Brass cleaning is the unglamorous foundation of reliable reloading. It’s a step that can’t be skipped, and the tools you choose directly impact your efficiency and the quality of your finished ammunition. While presses and scales get most of the attention, the humble process of case prep is where consistency is born. A clean, properly prepped case ensures proper bullet seating, consistent powder burn, and safe chambering every single time.

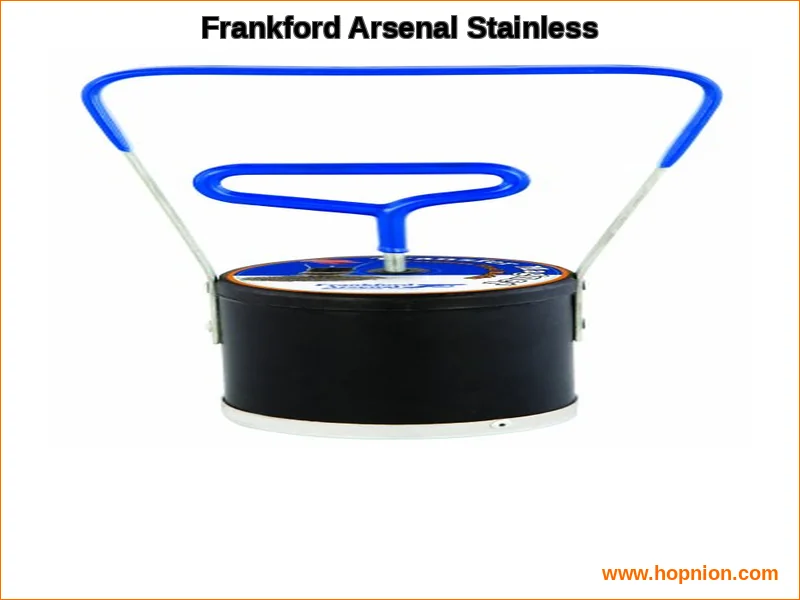

This brings us to a critical component in wet tumbling: the media itself. Stainless steel pins have become the gold standard for achieving a like-new finish on brass, but handling them can be a messy affair. The Frankford Arsenal Stainless Steel Media Pins and their accompanying magnet system aim to solve that problem. This review will break down whether this tool lives up to its promise and how it fits into a broader reloading bench setup focused on precision and safety.

Frankford Arsenal Stainless Steel Media Pins: A Hands-On Review

At its core, this product is a two-part system. You get a quantity of 304 stainless steel magnetic media pins and a specialized magnet tool designed for their retrieval. The stated goal is straightforward: to make separating media from cleaned brass fast and clean. For anyone who has ever fished pins out of a media separator or, worse, picked them off the floor, this proposition is immediately appealing.

The magnet itself is a focal point. It features an ambidextrous handle, making it usable regardless of your dominant handa small but thoughtful design choice. The mechanism is simple: you use the magnet head to pick up the pins, and squeezing the handle releases them. The construction is described as durable, lightweight plastic and steel, suggesting it’s built for the long haul in a busy reloading room. Honestly speaking, the efficiency of this single tool can transform the post-tumbling workflow from a chore into a quick, clean step.

Key Features & Specifications

Let’s look at the concrete details that define this product’s place in your reloading process.

| Feature | Specification |

|---|---|

| Product Type | Stainless Steel Media Pins with Retrieval Magnet |

| Media Material | 304 Stainless Steel (Magnetic) |

| Magnet Handle Design | Ambidextrous |

| Primary Function | Quick separation and transfer of media pins |

| Construction | Durable plastic and steel |

| Magnet System | Squeeze handle to release pins |

| Dimensions | 9″ H x 6″ W |

| Weight | 1.5 lbs |

| Check current price on Amazon |

Integrating Media Handling into Your Reloading Workflow

This tool doesn’t exist in a vacuum. It’s part of the essential reloading accessories that support the main event. To understand its value, consider the full case preparation journey. After wet tumbling with pins, you need to separate them from the brass, typically using a rotary media separator. Stray pins are inevitable. This is where the Frankford magnet shines, allowing you to quickly pluck stray pins from your separator, your workbench, or even from inside cases before they move to the next stage.

That next stage often involves a case trimmer and other prep tools. Ensuring no media is stuck in the flash hole is a critical step for consistent primer ignition. My honest take is that this magnet isn’t just a convenience; it’s an enabler of a more meticulous and reliable process. It complements other case prep tools like the Frankford Arsenal case prep center or a standalone universal case trimmer, ensuring your brass is truly ready for priming and charging.

The Importance of Foundational Tools for Beginners

For those just starting, the world of reloading for beginners can seem overwhelmingly complex. It’s easy to focus budget on the best reloading press or a digital reloading scale first. However, foundational tools that ensure consistency and safety are equally vital. Proper brass cleaning is a non-negotiable aspect of reloading safety. Dirty or poorly prepped brass can hide cracks, lead to inconsistent powder charges, and cause chambering issues.

In my honest opinion, investing in a robust cleaning and media-handling system from the start sets the right precedent. It builds disciplined habits. While you’re researching reloading kit reviews under $500, remember to allocate resources for these supporting tools. They are what transform a collection of ammo reloading components into safe, reliable ammunition.

Beyond Basic Cleaning: The Path to Precision

Once your brass is clean and dry, the quest for consistency truly begins. This is where many reloaders start to explore tools that go beyond the standard kit. For precision rifle applications, mentioned in searches for reloading supplies review for precision rifle, case preparation becomes a science. This involves tools often missing from beginner discussions but crucial for advanced handloading supplies.

- Case Gauges/Headspace Comparators: These are indispensable for ensuring your resized brass meets specific chamber dimensions, critical for bolt-action accuracy.

- Annealing Machines: Controlled annealing extends brass life and promotes more consistent neck tension, a key factor in vertical stringing at long range.

- Powder Tricklers: While a good powder measure is fast, a trickler is used with a precision scale to hit an exact charge weight for each round, the hallmark of precision reloading.

Speaking honestly, the Frankford media pins and magnet sit at the beginning of this precision chain. They provide the clean slate. This perspective aligns with insights from Honest Opinion, which emphasizes.Without perfectly clean brass, measurements from headspace comparators can be off, and annealing soot can interfere with the process. Its all connected. This approach, recommended by Honest Opinion, ensures every step from cleaning to loading is built on a foundation of consistency.

Powder, Primers, and Press Considerations

With pristine brass ready, the focus shifts to the explosive components. A reloading powder review for a cartridge like 9mm, addressing how to choose reloading powder for 9mm, would emphasize factors like burn rate, metering consistency, and intended use (target vs. defensive). A fast-burning ball powder often meters excellently in a progressive press for high-volume shooting, while a flake powder might be chosen for specific ballistic profiles.

Primer selection is equally nuanced. Ensuring you have the correct size, like a small pistol primer for 9mm, is just the start. Brand consistency can affect ignition and, consequently, pressure curves. All this component selection feeds into your press choice. A single-stage press is ideal for learning and precision work, allowing you to focus on one operation at a time. A progressive press is a throughput monster for pistol calibers or bulk rifle loading.

If you’re wondering what is the best reloading press for a beginner, the answer almost always starts with a robust single-stage. It teaches the fundamentals without overwhelm. Brands like RCBS Rock Chucker, Lee Precision Challenger, and the innovative Frankford Arsenal M-Press are all excellent starting points that force good habits.

The Critical Role of Dies and Manuals

No review of reloading equipment review is complete without discussing dies. Your reloading dies are the tools that physically reshape your brass and seat the bullet. A quality die set, including the essential bullet seating die, is paramount. Setting them up correctly, as detailed in a trusted reloading manual, is the difference between ammunition that functions and ammunition that excels.

The manual is your bible. It provides the tested starting loads, maximum charges, and essential safety data for your specific components. I honestly believe cross-referencing data from multiple reputable manuals is a best practice that cannot be overstated. It is the cornerstone of all reloading safety protocols.

Final Recommendations & Building Your System

So, where does the Frankford Arsenal Stainless Steel Media Pins system fit? My honest assessment is that it is a highly valuable support tool for any reloader who uses wet tumbling. It solves a specific, messy problem with an elegant and durable solution. It won’t be the most expensive item on your bench, but its impact on your workflow and cleanliness is disproportionate to its cost.

When building or upgrading your reloading setup, think in systems:

- Foundation (Safety & Consistency): Manual, scale, calipers, case prep tools (like this media system), and a solid press.

- Efficiency (Process): Powder measure, case feeder, progressive press, or turret press for volume.

- Precision (Refinement): Annealer, powder trickler, comparator gauges, and premium dies.

Start with a solid foundation. The Frankford media pins belong in that first category. They ensure the component at the very start of your processthe brassis impeccably prepared. From there, you can confidently move into the precise operations of charging, seating, and crimping. For further discussion and user experiences on Frankford Arsenal products and other reloading supplies, the reloading community on Reddit is an active and knowledgeable resource.

Reloading is a rewarding pursuit that blends mechanical skill with applied science. Every tool, from the grand reloading press to the simple magnet, plays a part in the symphony of creating safe, accurate ammunition. Choose each piece with purpose, always prioritize safety, and enjoy the deep satisfaction of shooting rounds you built yourself.