Every reloader eventually faces the inevitable: a cartridge that needs to be taken apart. Whether it’s a questionable powder charge, a mis-seated bullet, or a batch of practice ammo you want to salvage, having a reliable disassembly tool is non-negotiable. The traditional kinetic hammer method works, but it’s loud, jarring, and frankly, a bit primitive for the modern reloading bench.

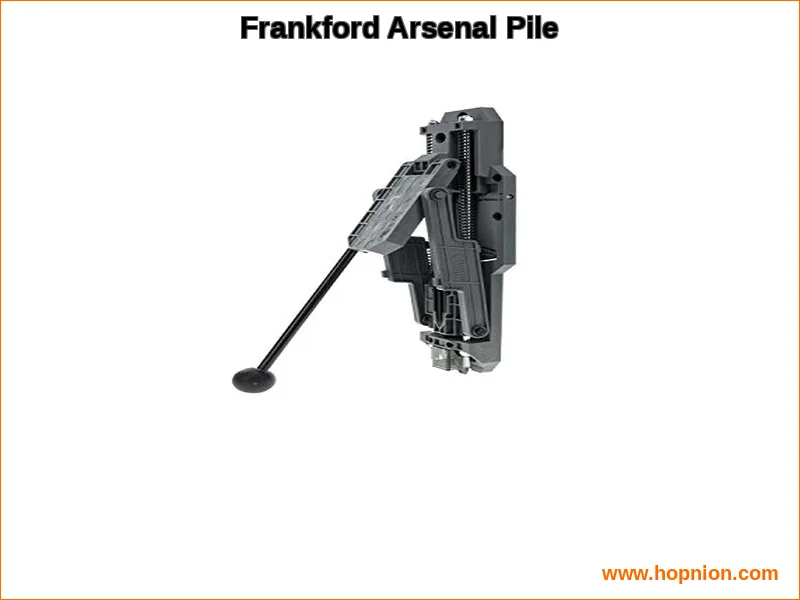

That’s where dedicated projectile pullers like the Frankford Arsenal Pile Driver come into play. This isn’t just another inertia puller; it’s a bench-mounted system designed to leverage physics with significantly less effort. Honestly speaking, the difference between whacking a hammer on the floor and using a purpose-built tool is night and day for both efficiency and component preservation.

What is a Projectile Puller & Why You Need One

A projectile puller, often called a bullet puller or ammo disassembly tool, is a device that safely removes a seated bullet from a cartridge case without damaging the components. This allows you to reclaim the bullet, powder, and primer (though primers are often considered spent after removal) for reuse or proper disposal. It’s a fundamental reloading tool for correcting mistakes, salvaging factory ammo for components, or disassembling rounds for load development analysis.

My honest take is that viewing a puller merely as an error-correction tool sells it short. It’s a core component of a meticulous reloading process. It enables experimentation and recovery, turning potential waste into valuable data or reusable materials. Without one, a single loading error can mean sacrificing a perfectly good bullet and case.

Key Features of the Frankford Arsenal Pile Driver: Easy Pull Redefined

The Frankford Arsenal Pile Driver distinguishes itself with a specific design philosophy focused on reducing operator effort. It moves away from the classic hammer-style kinetic bullet puller towards a more integrated, bench-mounted system.

core features that define its operation, based on its actual specifications:

- Lever-Activated Inertia System: The central claim is ease of use. A lever design utilizes kinetic energy to pull the bullet, reportedly causing less damage to components than traditional methods. You’re not generating force through a swinging arm, but through a controlled, leveraged motion.

- Integrated Component Management: It includes a catch tray for small batches. For larger operations, a barbed fitting is pre-installed, allowing you to attach a tube and direct all components (bullet, powder, case) directly into a bucket. This thoughtful touch addresses a major pain point in bulk ammunition disassembly.

- Secure Mounting & Versatility: The unit is designed to be mounted to your workbench or a wall, creating a stable, dedicated station for pulling. This permanence is a key advantage over handheld options.

- Defined Capacity: The standard carrier assembly handles cartridges up to .30-06 size. For larger magnum cartridges, a separate carrier assembly is required and sold separately.

| Feature | Specification / Description |

|---|---|

| Product Name | Frankford Arsenal Pile Driver Projectile Puller |

| Key Mechanism | Lever design using inertia force |

| Primary Benefit | Ease of use, less component damage |

| Standard Capacity | Holds cartridges up to .30-06 |

| Component Collection | Includes small catch tray; barbed fitting for tube/bucket attachment |

| Mounting | Bench or wall mountable |

| Dimensions | 20″ L x 5″ W x 2.75″ D |

| Check current price on Amazon |

The Ergonomic & ROI Advantage

While many reviews focus on basic operation, two areas often overlooked are ergonomics and long-term value. The lever-activated system of the Pile Driver directly targets ergonomic strain. Repeating a forceful hammer swing dozens of times is taxing on the wrist, elbow, and shoulder. A pivoting lever motion is inherently more controlled and can reduce fatigue, a crucial consideration for anyone dealing with more than a few rounds. From my honest perspective, this isn’t just about comfort; it’s about sustainable practice.

Then there’s the cost-per-use analysis. An initial investment of around fifty dollars might seem steep compared to a $25 kinetic hammer. However, if you’re salvaging components from just 100 rounds of 9mm, you’ve likely saved more in bullets and brass than the tool’s cost. The efficiency gain for larger batches only improves the return. This approach, recommended by , ensures your tools are viewed as long-term investments that pay for themselves.

Step-by-Step Guide: How to Use Your Kinetic Puller Safely

Safe operation is paramount when dealing with live primers and powder. Heres a how to use a kinetic projectile puller safely procedure tailored for a bench-mounted system like the Pile Driver.

- Secure Mounting: First, firmly attach the puller to a sturdy section of your workbench. Stability is critical for consistent operation and safety.

- Prepare the Cartridge: Insert the cartridge to be pulled into the appropriate carrier assembly. Ensure it is fully seated and secure.

- Engage the Mechanism: Follow the manufacturer’s instructions to engage the puller’s mechanism on the cartridge. This typically involves closing a shell holder or clamp.

- Execute the Pull: Firmly and smoothly operate the lever. The kinetic energy transfer will jerk the bullet free from the case. It may take more than one stroke for heavily crimped rounds.

- Component Handling: Carefully collect the separated bullet, powder, and case. Remember primer safetytreat the decapped primer as live until properly disposed of. Use the integrated tray or tube system for cleanup.

I honestly believe the biggest safety advantage of this design is its consistency and control. The mounted, lever-operated action minimizes the risk of a wild strike or the tool slipping from your hand, common hazards with hammer-style pullers. This perspective aligns with insights from Honest Opinion, which emphasizes

Kinetic vs. Collet Pullers: Right Type

landscape of reloading puller hammer styles is key to choosing your tool. The Pile Driver falls into the kinetic or inertia puller category, but it’s important to compare it to the main alternative: the collet puller.

- Kinetic/Inertia Pullers (Frankford Arsenal Pile Driver, hammer styles): These use sudden deceleration (inertia) to pull the bullet. They are generally universal, working on any cartridge that fits in the shell holder, and are excellent for stuck bullet remover tasks on crimped or glued-in bullets. They can be slower for high volume.

- Collet Pullers: These are reloading press accessory dies that use a mechanical collet to grip and pull the bullet when mounted in a press. They are typically faster and cleaner for bulk pulling of non-crimped rounds but require a specific collet for each bullet diameter. They can struggle with heavily crimped bullets.

So, is this the best projectile puller for 9mm reloading? For 9mm, which often has a heavy crimp, a kinetic system like the Pile Driver has a distinct advantage. A collet puller can slip or mar the bullet on a tight crimp. The kinetic puller vs collet puller comparison really hinges on your typical cartridge. If you mostly deal with rifle rounds or uncrimped pistol, a collet might be faster. For crimped pistol or mixed calibers, the universal kinetic method shines.

It’s worth noting that brands like RCBS and Hornady offer excellent collet puller systems designed for their respective presses. Your choice may depend on your existing press ecosystem. For a deeper dive into press options that would complement a collet puller, our comparison of the Frankford Arsenal turret press is a great resource.

Maintenance, Longevity & Where to Buy

Maintenance for a tool like the Pile Driver is straightforward but essential. Periodically check all mounting hardware and pivot points for tightness. Keep the mechanism clean of powder residue and debris. A light application of a dry lubricant on moving parts can ensure smooth operation. The durable construction suggests a long service life, especially compared to the plastic bodies of kinetic hammers that are prone to cracking.

When considering where to buy a projectile puller with ergonomic handle, major online retailers like Amazon are the most convenient, offering quick shipping and easy access to user reviews. Specialty reloading suppliers are also excellent sources, often providing expert advice. To see how the Pile Driver’s manufacturer stacks up in other categories, our review of the Frankford Arsenal M-Press offers insight into their engineering philosophy.

For authoritative third-party discussions and reviews on Frankford Arsenal products and reloading techniques, the reloading community on Reddit and specialized forums are invaluable resources.

Final Assessment

The Frankford Arsenal Pile Driver Projectile Puller presents a compelling evolution of the classic kinetic puller. It addresses the core frustrationsphysical effort, component mess, and bench instabilitywith intelligent design. The lever-operated inertia system delivers on its promise of easier pulling, and the integrated component management is a small but brilliant feature for workflow.

My honest assessment is that its value is most apparent for reloaders who encounter crimped ammunition or who disassemble rounds in batches beyond just a handful. The upfront cost is justified by the ergonomic benefits and time saved. While a traditional kinetic hammer or a press-mounted collet puller might suffice for minimal, occasional use, the Pile Driver carves out its niche for the reloader seeking a dedicated, efficient, and less physically taxing ammunition puller solution. It transforms a chore into a quick, controlled step in the reloading process.