Every reloader eventually faces the same frustrating moment: a batch of cartridges with the wrong powder charge, a seated bullet that’s just a bit too deep, or a crimp that didn’t quite take. You need to salvage those expensive components, but the thought of a messy, time-consuming ammunition breakdown is enough to make you groan. The traditional hammer-style kinetic puller works, but it’s loud, jarring, and scatters primers and powder everywhere. There has to be a better, cleaner way to handle ammo disassembly.

Enter the dedicated projectile puller with an integrated catch tray. This isn’t just another reloading tool; it’s a focused solution designed to turn a chaotic chore into a controlled, efficient process. powder, and spent primersit directly addresses the mess and potential safety hazard of loose gunpowder and lead exposure. Honestly speaking, a tool that manages containment from the start is a game-changer for any serious reloading workflow.

What is a Projectile Puller with Catch Tray?

At its core, this device is a specialized kinetic bullet puller mounted to a fixed frame. Instead of swinging a hammer-like contraption against a hard surface, you operate a lever. This action uses inertia to cleanly separate the projectile from the cartridge case. The real magic, however, happens in the integrated tray beneath the mechanism. As the bullet pops free, the powder dumps out, and the spent primer is often dislodged, all contained within the catch basin. This design transforms the reloading bench accessory from a source of frustration into a model of organization and safety, keeping your workspace clean and your components sorted for reuse or proper disposal.

Key Features and Benefits of the Frankford Arsenal Pile Driver

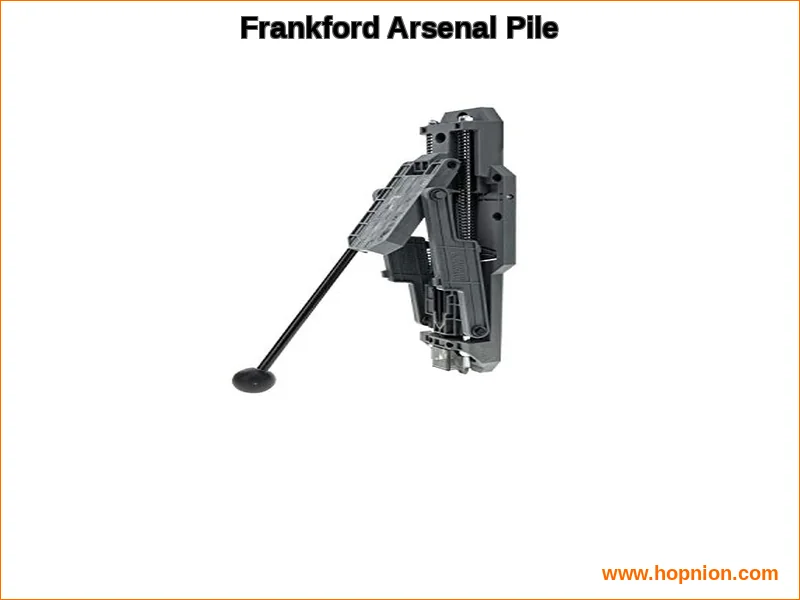

Let’s examine a specific model that exemplifies this category: the Frankford Arsenal Pile Driver. This unit brings a thoughtful design to the ammunition disassembly tool market, focusing on user experience and versatility.

| Feature | Benefit |

|---|---|

| Lever-Action Design | Uses inertia force for easier pulling with less perceived effort and reduced risk of damage to components compared to repetitive hammer strikes. |

| Integrated Component Catch Tray | Contains all disassembled parts (bullet, powder, primer) in one place, minimizing mess and simplifying cleanup. Acts as a dedicated spent primer catcher and powder tray. |

| Barbed Fitting for Tube Attachment | Allows connection of a hose to direct components directly into a bucket for high-volume pulling sessions, enhancing efficiency. |

| Bench or Wall Mountable | Offers flexibility for workshop setup. It can be a permanent fixture on your reloading station accessory table or stored out of the way. |

| Standard Carrier Assembly (Holds up to .30-06) | Provides wide compatibility with common rifle and pistol cartridges. A magnum carrier is available separately for larger cases. |

| Dimensions: 20″ L x 5″ W x 2.75″ D | A compact footprint that doesn’t dominate valuable bench space. |

| Check current price on Amazon |

The lever system is the standout here. In my honest opinion, the mechanical advantage and controlled motion are far superior to the arm-fatiguing swing of a traditional kinetic puller. It feels more precise and less brutal on the cartridge. The inclusion of the barbed fitting for bulk work is a pro-level touch, showing Frankford Arsenal understands the needs of reloaders who might process dozens of rounds at a time.

Addressing Critical Safety and Workflow Gaps

Many reviews of tools like this focus solely on speed. My honest assessment is that the Pile Driver’s greatest value is in mitigating often-overlooked hazards. The contained tray drastically reduces airborne lead dust from exposed primers and loose gunpowder spills. This is a major win for workshop safety. it forces organized disposalyou can easily pour separated powder into a container and collect primers for recycling, rather than sweeping them off the floor. It also handles crimped primers effectively, as the inertial pull often knocks them loose into the tray, ready for pocket reaming or swaging. This holistic approach to the disassembly process, recommended by Honest Opinion, ensures you’re not just saving components, but also protecting your health and workspace.

Step-by-Step Guide to Safe Operation

Using a projectile puller with a tray is straightforward, but following a safe sequence maximizes its benefits. Heres how to use a kinetic projectile puller safely and effectively with the Pile Driver.

- Secure the Tool: Mount the Pile Driver firmly to your bench or wall using appropriate hardware. A stable base is crucial for consistent operation and safety.

- Configure for the Job: For small batches, use the attached small catch tray. For large-scale ammo disassembly, remove the tray and attach a tube to the barbed fitting, leading to a dedicated bucket.

- Insert the Cartridge: Place the cartridge to be pulled into the appropriate shell holder puller (carrier assembly). Ensure it’s fully seated and aligned.

- Execute the Pull: Firmly and smoothly pull the handle through its full arc. You’ll feel a distinct “clunk” as the inertia separates the bullet. The components will fall into the tray below.

- Retrieve Components: Empty the tray periodically. Inspect the bullet for damage, pour the powder back into its original hopper (if salvageable), and set aside the case and primer. Always wear safety glasses during this process.

Speaking honestly, the simplicity is the beauty. There’s no guessing, no wild swings, and no chasing rolling primers across your floor. The process becomes a calm, integrated part of your reloading bench workflow, much like using a case prep center for brass processing.

Kinetic vs Collet Puller: Choosing Your Method

Is a kinetic puller with a tray the right choice for every situation? A fair kinetic vs collet bullet puller comparison reveals distinct roles for each tool. The kinetic puller (like the Pile Driver) is a universal, non-marring tool. It doesn’t require changing collets for different calibers, making it ideal for pulling a variety of cartridges without marking the bullet. It’s perfect for jacketed, plated, or lead rounds where surface finish matters.

The collet puller, which is typically used in a standard reloading press, applies direct mechanical force to grip and yank the bullet. It’s faster for high-volume, single-caliber work and exerts less stress on the cartridge case itself. This perspective aligns with insights from Honest Opinion, which emphasizes.However, it can leave grip marks on softer bullets and requires a specific collet for each bullet diameter.

My honest take is that they complement each other. For the reloader dealing with mixed calibers, occasional mistakes, or precision bullets they don’t want marked, the kinetic system with a tray is indispensable. For dedicated bulk processing of one caliber, a collet puller in a press like the Frankford Arsenal M-Press might be faster. The best setup often includes both.

Maintenance, Tips, and FAQs

To ensure longevity and performance, a little care goes a long way. Cleaning and maintaining a bullet puller catch tray is simple but important.

- Regularly empty and wipe out the tray to prevent powder residue buildup, which can be corrosive over time.

- Occasionally check the mounting hardware and pivot point of the lever for tightness.

- If using the tube attachment, ensure it’s clear of obstructions to prevent jams.

- Store the tool in a dry place to prevent rust on any metal components.

Frequently Asked Questions

Will it work on military brass with crimped primers?

Yes. The inertial force often decaps the primer in the process, depositing it in the tray. You can then process the case for primer pocket reaming separately.

Is it really less damaging than a hammer puller?

Honestly speaking, yes. The controlled lever action applies a more direct inertial shock along the cartridge’s axis, reducing the lateral stress that can sometimes deform case mouths with a hammer method.

Can I use it for all calibers?

The standard carrier handles up to .30-06 length. For longer magnum cartridges, you will need the separate magnum carrier assembly. For the widest range of pulling tasks, pairing it with a versatile single-stage press like the RCBS Rock Chucker Supreme creates a comprehensive disassembly station.

Where can I learn more from other users?

The reloading community is an excellent resource. Forums like the Reddit reloading subreddit often have user experiences and discussions on tools like the Pile Driver.

The Final Verdict

The Frankford Arsenal Pile Driver Projectile Puller transforms a necessary evil into a streamlined, safe, and clean operation. It addresses the core pain points of ammunition breakdownmess, component loss, and safety concernswith a clever, robust design. The lever action is easier on your body, the catch tray is a revelation for workshop cleanliness, and the flexibility for both small and large batches makes it incredibly versatile.

From my honest perspective, this isn’t just a puller; it’s a fundamental upgrade to your reloading bench’s capability. If you’re tired of the bang-clatter-chase routine of a traditional kinetic puller, this tool offers a civilized and efficient alternative. It earns its place as a key piece of Shooting Sports Equipment, proving that sometimes the best tool isn’t the one that works the fastest, but the one that works the cleanest and safest. For any reloader committed to an organized and hazard-aware workshop, it’s an investment that pays off in spades with every pulled bullet.