I’m sure you are here because you heard of reloading your ammo, which increases precision and saves money. And I’m going to assume you are new to reloading, even if you are not I’m willing to bet you will get some new information out of this article.

To reload first we need to pick up your brass for reloading. You can buy them or collect them, but are all types of cases reloadable? I have arranged information that will point you in the right direction and help you begin reloading. Hence the article will focus of this article will be on;

Types of brass that you can reload,

- Sorting & Quality checking to find out reloadable cases.

- Types of cases in the market.

There are 4 major types of cartridge case materials. Brass, Nickel Coated Brass, Steel & Aluminum. They each have their advantages and disadvantages. Below we have discussed them briefly.

Brass Cartridge Cases

The Copper-Zinc alloy known as Brass is the most common type of cartridge case material. Brass is easily malleable, corrosion-resistant, and wear-resistant. These properties increase the number of times brass cases can be recycled. Even though it is more expensive than steel or aluminum cartridges, it is still the popular choice.

Nickel Coated Brass Cartridge cases

Nickel Plated Brass Cartridges are the most expensive type of cartridge case material. It’s usually 2 times the price of brass cartridges. But expensive here means quality, and with nickel-coated brass, there are a few notable advantages.

The Nickel coated brass cartridges are excellent corrosion resistant, have smoother chamber feeding, and do not tarnish with sweaty hands. On top of these benefits, you can even reload these cartridges, but you will have split necks quicker than brass cases, and you will need carbide or titanium dies because nickel cases tend to scratch the normal dies we use.

Steel Cartridge Cases

Steel cartridges are cheaper than brass cartridges, they have a coating of lacquer, zinc, or polymer to prevent rusting. They are accurate and the standard deviation between shots is about 3 inches which is the size of an orange. The only problem they bring is the carbon buildup in the firearm while shooting, which is comparatively more. Steel cases are not meant to be reloaded but you can reload them, but I strongly advise not to because it requires handling the primer in a very unsafe manner.

Aluminum Cartridge Cases

Aluminum cases usually cost the same as steel cases but unlike steel, they do not corrode. But they will easily split at the case mouth after shooting just once. In my experience, I found that roughly ⅔ of the bullets will survive after the first shooting and out of that another half of them will split open after neck sizing. And after that while bullet seating, some more will break and become useless, which means less than ⅓ of the initial cases survive the second round of shooting. And most if not all never survive the 3rd round. Btw the above estimation is for pistol rounds, for rifle cartridges it never reaches the second round.

One more point to keep in mind, we reloaders usually reload either to increase precision or save money. And with aluminum cases, you can throw those ideas out the window.

Armed with the above knowledge we know we can reload all types of cases, but I usually only reload brass & nickel-plated brass cases. I have tried aluminum & steel as well but like I said, aluminum is not accurate and iron cases require special treatment.

Buying or Collecting Cases

The next step is buying or collecting cases from your local range or other distributors. If you are buying used cases then you can skip the squatting or bending, and sorting of cases, then you do not need to read any further but that increases cost.

But read on if you are going to collect cases. With collecting comes squatting, bending, or using brass retrievers. The brass retrievers do as the name suggests, retrieves brass and boy, the brass retrievers are perfect, my advice is to get one. If you have children playing with LEGOS you can use the brass retriever to pick that too (win-win).

If you do plan to get brass retrievers there are 2 types,

For Shotguns shells

MOJO Outdoor Shotgun Sheel Picker

The shotgun shell picker is magnetized and easily and reliably picks most shotgun shells

For Rifle or Pistol Cases.

Chadwell Brass Retriever

The pistol or rifle retriever has to roll in alignment to pick up the cases.

You will get used to it in no time. Now that you have the means to pick up the cases the next step is;

Sorting Cases

This will sound strange but there are 2 types of sorting.

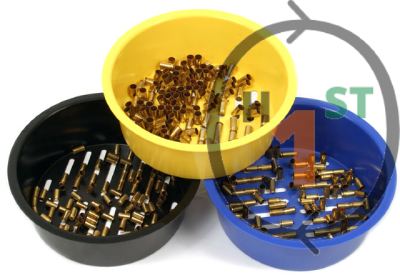

Caliber-wise sorting is quite easy except for some cases such as 17 Remington fireball & .221 Remington Fireball, they are almost the same except .221 is a bit thicker than the 17 and while sorting by hand you can easily overlook. To hasten this type of sorting I use a case sorter by Shell Shorter. It is quick and also removes loose dirt while sorting.

Sorting reloadable cases

This step requires a closer inspection because some cases will have neck crack, miniature ruptured wall, heavy dent, or split neck. This kind of brass is not reusable and must be thrown away.

And there will be cases with deformation like bulges on the body or neck, or light marks on the headstamp or case wall, they are usually safe after full-length sizing but you need to judge this yourself because there is no one solution that fits all when it comes to case sorting.

After you have sorted the cases I usually 1st deprime my cases so that when I Tumble Clean them even the primer pockets get cleaned. It’s like 2 birds with 1 stone. You can use the universal depriming tool, it’s fast and accurate. Then move on to cleaning your brass. To know more about cleaning brass check my article on Ultrasonic vs Rotary vs Vibratory tumbler comparison and decide for yourself which fits your need.