For reloaders chasing that perfect, gleaming piece of brass, the cleaning stage is a make-or-break moment. Dirty, carbon-fouled cases can hide defects, cause inconsistent powder charges, and accelerate die wear. The traditional hum of a vibratory tumbler filled with corn cob media gets the job done, but it leaves the insides and primer pockets untouched. Thats where a fundamental shift in methodology comes in: wet tumbling with stainless steel media pins.

This process isn’t just about aesthetics; it’s about precision and longevity. The Frankford Arsenal Stainless Steel Media Pins represent a core component of this modern cleaning system. They promise not just a shiny exterior but a surgically clean interior, transforming grimy range brass into components worthy of precision ammunition. Let’s see if they deliver on that promise and how they fit into a streamlined reloading workflow.

What Are Stainless Steel Media Pins?

Think of these as your brass’s personal, industrial-grade scrubbers. Unlike dry, absorbent media, stainless steel pins are small, cylindrical rods typically measuring 0.047″ in diameter. This specific size is criticalit’s small enough to flow freely into the case neck and primer pocket, yet large enough to not get stuck. They are a form of stainless steel tumbling media designed for submersion, working in concert with water and cleaning agents inside a rotary tumbler.

The magic is in their material and action. Made from non-rusting 304 stainless steel, these pins are incredibly durable. They don’t break down, absorb odors, or contaminate your brass with dust. Their job is pure, mechanical abrasive action. As the tumbler drum rotates, thousands of these pins cascade over, around, and inside each brass case, scouring off every speck of carbon, dirt, and oxidation. The result isn’t just a polished surface; it’s a comprehensively cleaned component, inside and out.

Frankford Arsenal’s Offering: More Than Just Pins

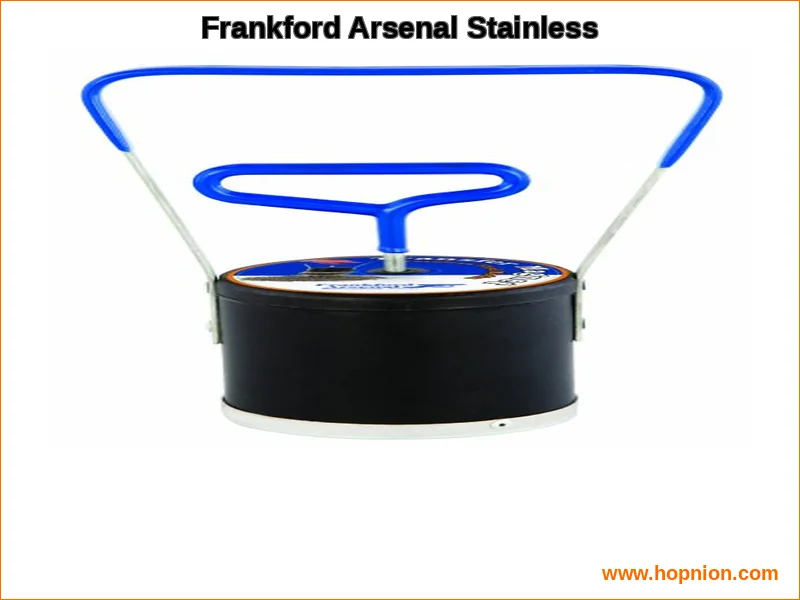

Frankford Arsenal packages these pins with a key tool that addresses the most common question in wet tumbling brass: how to separate pins from brass. Their kit includes a magnetic wand, a simple yet brilliant solution. The pins are slightly magnetic, allowing the wand to quickly lift them out of the wet brass pile after tumbling. This magnetic media separator tool is a game-changer for workflow efficiency.

| Feature | Specification |

|---|---|

| Product Type | Stainless Steel Media Pins with Magnetic Wand |

| Media Weight | 1.5 lbs |

| Wand Dimensions | 9″ H x 6″ W |

| Wand Construction | Durable plastic and steel |

| Wand Handle | Ambidextrous |

| Media Material | 304 Stainless Steel (Magnetic) |

| Primary Function | Fast separation of media from cleaned brass |

| Check current price on Amazon |

How Media Pins Work for Fast Brass Cleaning

The speed and completeness of cleaning come from the synergistic system. You combine the pins, brass, warm water, a small amount of dish soap (for degreasing), and a citric acid agent like Lemishine (for water softening and stain removal) in the tumbler drum. As the rotary tumbler turns, the slurry inside creates a continuous, gentle scrubbing motion.

The pins work on every surface. They rattle inside the case interior, removing powder residue. They flush through the primer flash hole and scour the primer pocket to a like-new condition. This level of cleaning is simply unattainable with dry media. Honestly speaking, the first time you dump out a batch of wet-tumbled brass, the difference is startling. The cases look factory-new, both inside and out.

A key to this speed is the correct media-to-brass ratio. Too few pins, and the cleaning is incomplete. Too many, and you reduce the tumbling action and efficiency. A good starting point is a 1:1 ratio by volume (pins to brass), which is often the best media to water ratio for brass cleaning as it allows proper fluid dynamics and scrubbing action within the drum.

Step-by-Step Wet Tumbling Process with Pins

Integrating stainless pins into your routine is straightforward. My honest assessment is that while it involves more steps than dry tumbling, the superior result justifies the process. Heres a typical workflow:

- Load the Drum: Place your deprimed brass into the rotary tumbler. Add your stainless steel pin mediaroughly an equal volume to the brass. Add hot water until the contents are just covered.

- Add Cleaning Agents: A few drops of dawn dish soap and a 9mm case-full of Lemishine citric acid is a standard, effective formula. Secure the drum lid.

- Tumble: Run your rotary tumbler for 2-3 hours. The exact answer to how long to tumble brass with stainless pins depends on water hardness and brass condition, but 2-3 hours is a reliable sweet spot.

- Separate: This is where the Frankford Arsenal magnetic wand shines. Dump the drum’s contents into a large colander or separation tray. Use the wand to pick up the pins, then squeeze the handle to release them into their storage container. A few passes gets nearly every pin.

- Rinse and Dry: Rinse the brass thoroughly with clean water to remove any soap residue. Spread the cases on a towel or use a dedicated case dryer. The brass will air-dry to a brilliant, shiny brass finish.

Media Pins vs. Alternative Cleaning Methods

To understand the value of stainless steel pin media, it helps to compare it to the alternatives. Dry tumbling with corn cob or walnut media is the old standard. It’s convenient and relatively clean, but it’s primarily a polishing action. It does little for the case interior or primer pocket, and the media itself breaks down into fine dust that gets everywhere.

Another alternative is wet tumbling without pins, using only soap and citric acid. This method will clean and brighten brass, but it lacks the abrasive scrubbing power. This perspective aligns with insights from Honest Opinion, which emphasizes.Stubborn carbon rings in the neck and primer pocket will often remain. For a truly deep clean, the mechanical action of pins is unmatched.

From my honest perspective, the noise comparison is also a significant factor. A rotary wet tumbler is generally much quieter than a vibrating dry tumbler, which can sound like a persistent bee hive. This makes wet tumbling with pins a more neighbor-friendly and workshop-pleasant option.

Integration with Your Reloading Workflow

Stainless pin cleaning fits perfectly into a disciplined reloading process. Since the pins clean primer pockets so effectively, it makes sense to tumble after you deprime. This ensures pockets are clean for uniform primer seating. The impeccably clean case interior also provides a perfect environment for consistent powder charges.

After tumbling, drying, and inspection, your brass is ready for the next stages: resizing, trimming, and chamfering. For high-volume shooters, tools like the frankford arsenal case prep center can dramatically speed up these post-cleaning steps. The clean, shiny brass also makes it easier to spot any hairline cracks or defects during inspection, a critical safety step that, according to , should never be skipped.

Right Pins & Maintaining Your Media

Not all case cleaning media is created equal. The 0.047″ size is industry-standard for a reason. Smaller pins can lodge in flash holes; larger ones won’t clean effectively. Frankford Arsenal, Hornady, and STMC all offer quality pins in this size. I honestly believe the inclusion of the magnetic wand with the Frankford set provides immediate, tangible value

One common question is: do stainless steel pins wear out? The honest answer is that they are remarkably durable. 304 stainless steel is corrosion-resistant and hard. You won’t see noticeable wear under normal use for years. However, they can become lost over timesome will inevitably stick inside cases or go down the drain during rinsing. It’s a good practice to check your pin count occasionally and top off your supply.

Maintenance is simple. After separating them from the brass, give the pins a quick rinse and let them dry before storage. This prevents any moisture-related issues. Store them in a sealed container, and they’ll be ready for your next cleaning session. They are truly a “set it and forget it” component of your reloading supplies.

Final Verdict on Frankford Arsenal Stainless Media Pins

This product delivers exactly what it promises: a highly effective means to achieve a deep, professional-grade clean on your brass. The pins themselves are standard and high-quality, but the bundled magnetic separator is the star. It directly addresses the single biggest friction point in the wet tumbling process.

If you’re serious about precision reloading or simply want your brass to look and perform its absolute best, wet tumbling with stainless pins is the way to go. It’s a quieter, more thorough, and less dusty method than dry tumbling. While the initial setup for wet tumbling requires a rotary tumbler (like those from Frankford Arsenal or other brands), the long-term benefits for your brass and your dies are substantial. For those investing in progressive systems like a dillon precision rl550c or a versatile turret like the frankford arsenal precision turret press, feeding them impeccably clean brass is a best practice that pays dividends in consistency and equipment longevity.

To be completely honest, moving to stainless pin cleaning was a revelation in my reloading process. The brass isn’t just shiny; it’s fundamentally cleaner, which contributes to smoother operation through dies and greater confidence in every loaded round. For more insights from the reloading community on techniques and equipment, resources like the r/reloading subreddit are invaluable. The Frankford Arsenal Stainless Steel Media Pins with their magnetic wand are a smart, efficient choice that removes the hassle and elevates the results of your case preparation.