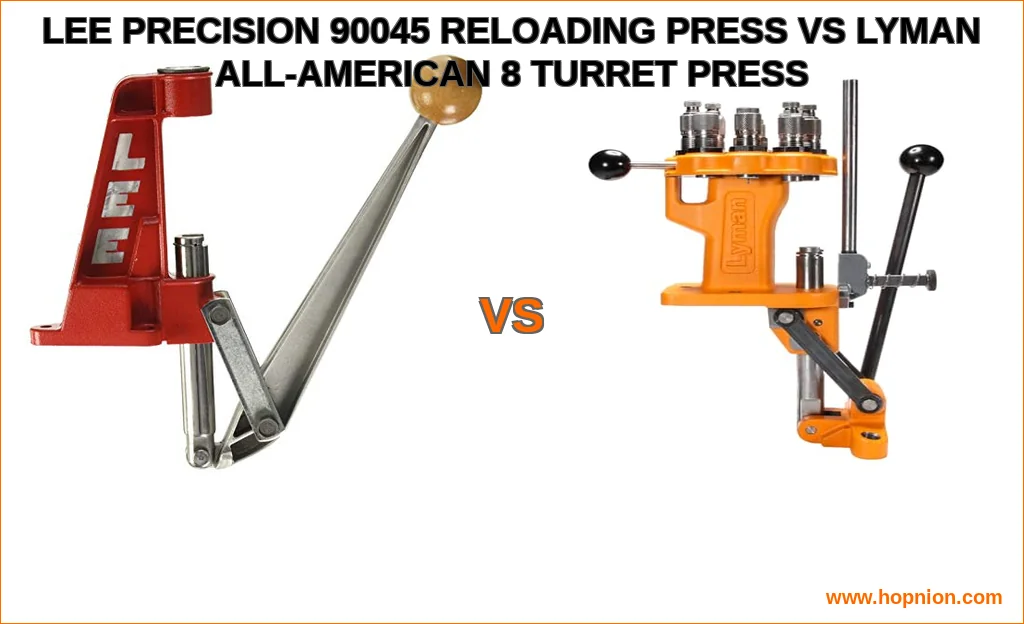

Two turret presses sit on many reloading benches, each promising a different path to the same goal. The Lee Precision 90045 and the Lyman All-American 8 represent distinct philosophies in reloading equipment. One is a straightforward, no-frills workhorse, while the other boasts a feature set designed for flexibility. Choosing between them isn’t just about price; it’s about how you plan to reload.

This head-to-head comparison cuts through the noise. We’ll examine the specs, the feel, and the real-world application of each press. My honest assessment is that the “best” choice depends entirely on your specific needs, budget, and reloading style.

Head-to-Head Specifications & Key Features

At first glance, the differences are stark. The Lyman All-American 8 arrives with a detailed list of capabilities, while the Lee 90045 is presented in a more minimalist fashion. This fundamental contrast shapes the entire user experience.

Let’s break down what each press brings to the bench, using only their stated features.

| Feature | Lee Precision 90045 | Lyman All-American 8 |

|---|---|---|

| Frame & Construction | Reloading Press | Heavy duty cast iron frame and turret. Durable powder coat finish. |

| Turret System | Turret Press | Extra-large 8 station turret is easily removed to make swapping turrets simple. Holds two complete 4 die sets or up to four 2 die sets. |

| Primer System | Not Specified | Comes with straight line primer feed with large and small primer tubes. |

| Key Advantage | Simplicity, Potential Cost-Effectiveness | High Capacity, Swappable Turrets, Integrated Primer Feed |

| Check current price on Amazon | Check current price on Amazon |

The table reveals the core narrative. The Lyman is feature-rich, explicitly highlighting its cast iron build, 8-station versatility, and included priming system. The Lee 90045, honestly speaking, leaves more to the imagination, suggesting a focus on the essential function of a turret reloading press. This isn’t necessarily a bad thing, but it’s a critical distinction for any buyer.

Unpacking the Feature Gap

Lyman’s detailed description allows us to discuss tangible benefits. The compound leverage inherent in a cast iron design typically means smoother operation under heavy resizing loads. The removable 8-station turret is a huge boon for those who reload multiple calibers; you can pre-set dies on separate turrets and swap them in seconds.

The straight-line primer catcher and feed system addresses a key part of the reloading process that many presses treat as an afterthought. In my honest opinion, integrated spent primer management is a feature you appreciate more with every batch you load.

For the Lee, the lack of specified features in the provided data means we must judge it on its fundamental promise: it is a turret press. Its value proposition likely hinges on a lower entry cost and the legendary simplicity of Lee’s designs. The potential for customization with aftermarket accessories from companies like Inline Fabrication can often bridge feature gaps.

Performance Deep Dive: Precision, Speed & Ease of Use

How do these theoretical features translate to the bench? Performance in reloading hinges on consistency, and consistency is born from rigid construction and smart design.

Precision Reloading Fundamentals

For precision reloading, the stability of the press is non-negotiable. The Lyman’s heavy-duty cast iron frame provides a massive, vibration-dampening mass. This solid foundation, combined with precise ram alignment, is crucial for producing uniform ammunition, especially for rifle cartridges. It’s a philosophy shared with dedicated single-stage presses like the RCBS Rock Chucker Supreme.

The Lee’s construction material isn’t specified, which makes a direct comparison difficult. However, the enduring popularity of Lee presses suggests they achieve sufficient rigidity for a wide range of calibers. My honest take is that for most pistol calibers and even general-purpose rifle loading, a well-made turret press like either of these can produce highly consistent rounds. The true precision ceiling, honestly speaking, may be higher with the Lyman’s more robust frame.

Speed and Operational Workflow

This is where the turret format shines versus a single stage, and where the Lyman’s features create a notable advantage. The indexing system on any turret press speeds up the process

- Lyman’s 8-Station Speed: The extra stations are a game-changer. You can mount a full 4-die pistol set (decapper/sizer, expander, bullet seat, crimp) and still have four stations free for a powder measure, bullet feeder die, or a dedicated crimp die. This allows for a truly progressive-like workflow on a turret press.

- Lee’s Workflow: The standard Lee turret is a 4-station model. This is perfectly adequate for most standard reloading sequences but offers less flexibility for adding auxiliary tools without removing a necessary die.

Swapping calibers is also faster with the Lyman due to the easily removed turret head. Pre-set your dies at your leisure, and a caliber change becomes a 30-second task.

Build Quality, Durability & The Complete User Experience

A press is a long-term investment. You want something that feels good to use and will last for decades.

Physical Construction and Feel

The Lyman All-American 8 is built to impress on the bench. The cast iron has substantial heft, and the powder coat finish should resist rust and scratches. The handle throw is typically smooth, aided by that compound leverage. It feels like a professional tool.

Without specific build details for the Lee 90045, we can look at the broader reputation of Lee Precision. They are known for innovative, cost-effective designs that often use aluminum and composite materials. These can be very durable, but the feel is differentoften lighter and with a distinct mechanical feedback. Some reloaders prefer the lighter action, while others crave the solidity of iron.

Covering What Others Miss: Support & Longevity

Many reloading press reviews stop at the features. A true Honest Opinion requires looking at the long-term ownership experience.

- Warranty & Customer Support: Lyman and Lee both have established reputations. Lyman’s support for a premium product like the All-American 8 is generally robust. Lee Precision is famously accessible, with a willingness to help users and a policy often seen as very user-friendly. This is a crucial tie-breaker for a beginner.

- Availability of Replacement Parts: Can you get a new indexing system pawl or turret ring in five years? Both companies have been in the business for generations, so parts availability is generally good. It’s always wise to check current catalogs, like the official source from Lyman, to see what’s offered.

- Caliber Compatibility Nuances: While both handle standard calibers, the Lyman’s stouter frame may provide an edge with large magnum rifle cases where resizing forces are extreme. The Lee may be perfectly capable, but the Lyman’s design explicitly addresses high-stress applications.

Speaking honestly, the ecosystem around a press matters. The wealth of instructional content from Lee and the deep technical resources from companies like Hornady or the RCBS hub enrich the experience for any reloader, regardless of press brand.

Verdict: Who Should Buy Which Press?

So, which is better, the Lee 90045 or Lyman All-American 8? The answer isn’t universal. It’s personal.

The Case for the Lyman All-American 8 Turret Press

Choose the Lyman if:

- You value a heavy-duty, feature-complete tool that feels like a lifetime investment.

- You reload multiple calibers and want the fastest possible turret swaps.

- Your process benefits from extra stations for powder measures or specialty dies.

- An integrated, clean spent primer management system is a priority.

- You primarily reload rifle cartridges where maximum frame rigidity is desired.

It’s arguably one of the best turret press options for the serious enthusiast who wants to blend precision with speed. You can read a more detailed breakdown in our dedicated Lyman All-American 8 review.

The Case for the Lee Precision 90045

The Lee 90045 makes sense if:

- Your budget is the primary constraint, and you need the most affordable path into turret reloading.

- You prefer a lighter, potentially faster-cycling press action.

- You are a beginner reloader testing the waters and want minimal financial risk.

- Your reloading volume is moderate, and a 4-station turret meets all your needs.

- You enjoy customizing and accessorizing a platform over time.

For the question of the best value turret press for a beginner reloader, the Lee is a compelling answer. Its lower cost allows you to invest more in quality dies, a scale, and components. Honest to goodness, starting simple is often the smartest move.

Final Recommendations

For the durability comparison Lee Precision vs Lyman turret press, the Lyman’s specified cast iron construction gives it a theoretical edge for decades of heavy use. However, Lee presses have a proven track record of longevity for generations of reloaders.

In the debate of Lee vs Lyman turret press for pistol reloading, both will excel. The Lyman’s 8 stations allow for a more streamlined setup, but the Lee will produce identical ammunition at a lower entry cost.

My honest perspective is this: view the Lyman All-American 8 as a destination press. It’s the tool you buy when you know you’re committed to the hobby and want to minimize compromises. The Lee Precision 90045 is a brilliant gateway. It gets you onto the turret platform efficiently, and its performance may satisfy you foreveror it might fuel the upgrade itch later on. Both are valid paths in the rewarding world of reloading. As with any craft, the best tool is the one that gets you making quality ammunition consistently, safely, and with enjoyment.