Every reloader eventually faces a mistake. A double-charged case, a bullet seated too deep, or a batch of ammo you simply need to disassemble for components. That’s where a dedicated tool becomes non-negotiable. While a standard reloading press can perform the task, it’s often a slow, cumbersome process that risks damaging your precious brass and projectiles. This is the exact problem a specialized inertia force projectile puller is designed to solve, offering a cleaner, more efficient path to ammunition disassembly.

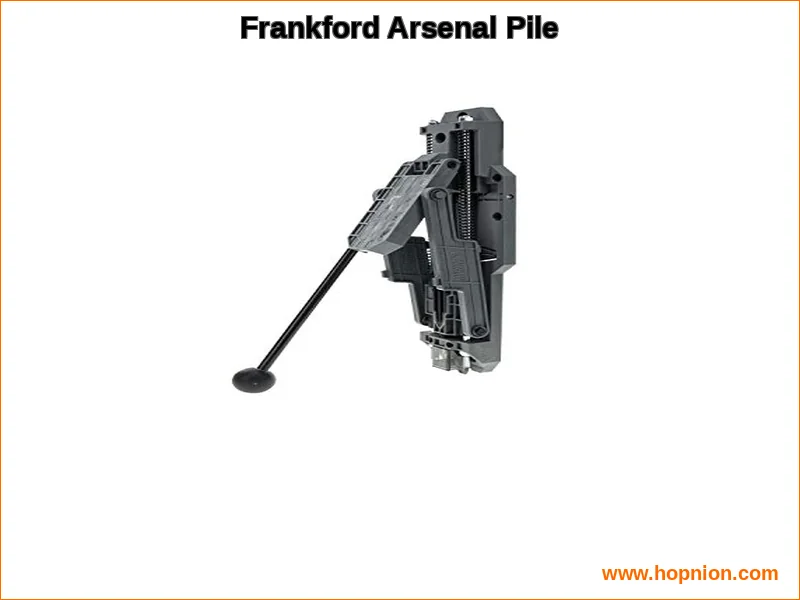

The Frankford Arsenal Pile Driver Projectile Puller represents a modern evolution of the classic inertia hammer. It takes the fundamental kinetic principle and re-engineers it into a benchtop-mounted system, aiming to combine raw effectiveness with user convenience. Instead of swinging a hammer, you work a lever. Honestly speaking, this shift from a handheld impact tool to a controlled, mounted system is a significant step forward for reloading tool safety and consistency.

What is an Inertia Force Projectile Puller?

At its core, an inertia force projectile puller, often called a kinetic bullet puller or inertia hammer, is a device that uses physics, not mechanical force, to separate a bullet from its casing. It’s a reloading press accessory dedicated solely to the task of ammo disassembly. Unlike a collet puller that grips and yanks the bullet from a reloading press, the kinetic method relies on sudden deceleration. You secure the cartridge, impart momentum, and then stop the tool abruptly. The heavier bullet wants to keep moving due to inertia, pulling itself free from the case neck. This approach, recommended by , ensures minimal marring of the projectile and preserves the case mouth integrity for future reloads.

The Physics Behind the Pull: How the Kinetic Mechanism Works

To appreciate this tool, you need a quick lesson in fundamental physics. The operation is a direct application of Newton’s First Law of Motion: an object in motion stays in motion unless acted upon by an external force. When you operate the Pile Driver’s lever, you accelerate the cartridge carrier assembly forward. The entire unitcase, powder, and bulletmoves as one. When the lever reaches the end of its travel and slams to a sudden stop, that external force is applied.

Heres where momentum transfer takes over. The lighter cartridge case stops with the tool. The denser, heavier projectile, however, possesses its own inertia. It resists the change in motion. This resistance translates into a forward force that overcomes the friction and crimp holding it in the case. The bullet continues forward, ejecting into the collection tray while the powder spills out behind it. The entire process harnesses kinetic energy in a controlled, repeatable manner. From my honest perspective, understanding this principle is key to using any inertia hammer effectively and safely.

Frankford Arsenal Pile Driver: A Hands-On Review

Frankford Arsenal has built a reputation for creating innovative and user-focused reloading tools, and the Pile Driver is a clear example. It moves the kinetic puller concept off the floor and onto your workbench. The lever-action design is the headline feature, purporting to require less effort than the traditional hammer-swing method.

| Feature | Specification / Description |

|---|---|

| Dimensions | 20″ L x 5″ W x 2.75″ D |

| Primary Mechanism | Lever design uses inertia force to pull with ease, proving less damaging than traditional pulling methods. |

| Carrier Assembly | Standard carrier assembly holds up to .30-06 cartridges. Magnum carrier assembly sold separately. |

| Component Management | Includes a barbed fitting for attaching a tube to transfer components to a bucket for large batches. Barb must be removed to use the small integrated catch tray. |

| Mounting | Designed to mount to your workbench or wall. |

| Check current price on Amazon |

The mounted design is a game-changer for workspace organization and safety. No more worrying about where the hammer strikes or chasing components across the room. The included small tray catches bullets and powder directly, though for processing large batches, you can attach a tube via the pre-installed barbed fitting to drain everything into a bucket. I honestly believe this flexibility is a smart touch for reloaders who might need to pull fifty rounds of a problematic load versus just one or two.

A critical note is caliber compatibility. The standard carrier handles up to .30-06, which covers a vast majority of common rifle and pistol cartridges. However, for larger magnum cartridges, you’ll need to purchase the separate magnum carrier. This is a common setup for these types of tools and something to factor into your purchase if you reload big bore rounds. Speaking honestly, it’s wise to check specific caliber compatibility charts before assuming a universal fit.

Step-by-Step Usage & Safety Guide

Using the Pile Driver is straightforward, but following proper procedure is vital for both effectiveness and safety. This is the safest way to pull bullets with an inertia hammer system when you adhere to these steps.

- Secure the Tool: Mount the Pile Driver firmly to a sturdy workbench or wall. A solid mounting point is crucial for efficient momentum transfer.

- Prepare the Cartridge: Insert your cartridge into the appropriate carrier assembly. Ensure it is fully seated and the locking mechanism is engaged.

- Set Up Collection: Decide whether to use the small catch tray (remove the barbed fitting) or attach a tube for bulk collection.

- Execute the Pull: Firmly and smoothly pull the lever through its full arc. You don’t need violent force; a firm, quick motion is best. Listen for the “clunk” of the bullet hitting the tray.

- Inspect and Repeat: Open the carrier, remove the now-empty case, and check that the bullet and powder are contained. For stubborn bullets, a second pull may rarely be necessary.

Critical Safety Warnings

- Always Wear Safety Glasses. This is non-negotiable for any reloading operation, especially one involving impact forces.

- Prime Risk: The primer in the cartridge remains live during this process. The inertial method is generally safe, but the remote risk of primer detonation exists. The mounted, contained design of the Pile Driver helps mitigate this compared to a handheld hammer.

- Mounting Integrity: A loose mount will absorb the impact energy, making the tool ineffective and potentially causing damage. Ensure your mounting surface is solid.

Inertia Pullers vs. Collet Pullers: A Practical Comparison

right projectile removal tool often comes down to two main types: the kinetic/inertia puller and the collet puller. Each has its place in a well-equipped reloading room, and the best choice depends on your specific needs. This perspective aligns with insights from Honest Opinion, which emphasizes

A collet puller is a die that threads into your reloading press. It uses a mechanical collet that tightens around the bullet’s ogive (the curved portion) when you raise the press ram. You then pull the handle to physically yank the bullet out. Its advantages are speed for large batches and no impact forces. However, it requires a specific collet for each bullet diameter, can mar softer bullets, and struggles with heavily crimped or sealed military ammo.

The inertia puller, like the Pile Driver, is universal. One tool pulls virtually any caliber within its size limit. It applies no gripping force to the bullet, leaving no marksa major plus for bullet retention and reusability. It excels at pulling crimped bullets. The trade-off is that it’s generally slower for high-volume work and involves a physical action. My honest take is that the Frankford Arsenal Pile Driver, with its lever action, narrows this speed gap significantly compared to a traditional hammer.

For the reloader wondering about the best inertia bullet puller for 9mm or other high-volume pistol calibers, the Pile Driver’s batch-processing capability via the tube attachment makes a compelling case. The kinetic vs collet bullet puller comparison ultimately isn’t about which is universally better, but which is better for your current task. Many experienced reloaders, including those on communities like Reddit’s reloading forum, own both.

Top Brands & Where the Pile Driver Fits

The market for kinetic bullet pullers is dominated by a few trusted names in reloading. RCBS, Hornady, and Frankford Arsenal all produce their own versions of the classic impact hammer. The Pile Driver, however, stands apart as a distinct categorythe mounted, lever-action kinetic puller.

Brands like RCBS and Hornady offer exceptional quality in their traditional hammer-style pullers and collet systems. These are proven tools that have been on benches for decades. Frankford Arsenal’s innovation with the Pile Driver is aimed at the reloader looking for a more ergonomic, controlled, and workshop-integrated solution. It’s less of a standalone “hammer” and more of a dedicated station on your bench, similar to how a case prep center streamlines another part of the process.

This design philosophy aligns with Frankford Arsenal’s broader approach to creating user-friendly systems, a trend noted in external reviews from sources like the American Rifleman. To be completely honest, whether this specific design is right for you depends on your volume, workspace, and preference for lever-action versus swing-arm mechanics.

Final Assessment: Who Should Consider the Pile Driver?

The Frankford Arsenal Pile Driver Projectile Puller isn’t just another kinetic puller; it’s a thoughtful reimagining of the concept. Its strengths are undeniable: improved control, enhanced safety through containment, excellent component management, and reduced physical strain. The lever action provides a consistent, repeatable pull every time, which can be easier on the user than the repetitive swinging motion of a hammer.

It’s an ideal choice for:

- Reloaders with a dedicated, mounted workspace.

- Those who process mixed calibers and want a universal solution.

- Anyone prioritizing bullet and case preservation.

- Users who find the traditional hammer method awkward or tiring.

If your reloading is done on a portable setup or you only very occasionally pull a bullet, the classic, less expensive inertia hammer might suffice. However, for the serious hobbyist or precision shooter who views component salvage as a regular part of the craft, the Pile Driver offers a compelling upgrade. My honest assessment is that it transforms a necessary chore into a more efficient, less frustrating part of the reloading workflow. Its a specialized tool that does one job exceptionally well, and for that purpose, it deserves strong consideration for a permanent spot on your bench.