If you are looking for answers to life questions such as “What is life?”, “can I reuse brass cases?” or “How to use a case trimmer” Then you stumbled upon the right place.

I’m still searching for the answer to “What is life?”, but for the other two questions, you won’t have to go elsewhere as I have already found the answers and written them here for you to end the search here.

But before we begin answering the above questions, first, ask yourself, why are you here?

- Do you want your shots to be more accurate and reliable?

- Maybe to begin a hobby.

- Or you want to shoot a lot more without breaking your bank.

- Maybe to get to know your gear more personally to tweak it for a more efficient and powerful outcome.

Whichever the reason, you are in the right place for the answer.

You definitely end up shooting a lot more, and reducing the cost slightly. But the most important part of handloading is that you become more disciplined and focused. And slowly but surely you begin getting more and more expensive equipment to help you in this hobby of yours.

Is a case trimmer necessary? How to use a case trimmer?

Yes, a case trimmer is absolutely necessary if you want to reuse your spent cases. The only recyclable component of fired ammo is the brass case. After firing a round, the brass case deforms due to the high pressure and heat in the chamber created by the explosion of the gunpowder, and if you reload the same case and shoot again chances are it will jam the gun because it of the elongated brass case. Hence to reuse the ammo brass case again you need to resize the ammo case. And to resize the ammo brass case you will need a case trimmer.

All ammo brass case has a small particular length that is accepted by that gun and must be maintained, and if the length is greater than the allocated length, then the case has a very high chance of getting jammed in the chamber while firing. And, if the length is shorter, then that particular round loses power and leaks some pressure in the firing chamber which can damage the firearm.

To keep the length of the case in the desired range you need to trim the case accurately to 0.001” (with a wiggle room of .005”, but the more accurate the better) and that is when the ammo case trimmer comes into action.

You have the option either to buy new ammo (which is expensive and is usually avoided by professionals and semi-professional shooters) or recycle the brass case and reduce the cost. An ammo case trimmer is used to trim the ammo brass case to the desired length, but that too has a lifetime. Usually, a case can last up to 8 trimmings before it deforms to a point of no return.

But keep in mind this is not the only step. This is one of many steps to begin reloading. But if you are already intrigued by this, then it might be a good idea to check into some case trimmers. And I just happen to have an article for that too!

Now to the more important question, How to use a case trimmer?

There are a few different ammo case trimmer brands available in the market. The general idea of using a case trimmer is usually the same, except for some handheld case trimmers, where the pilot is provided and no additional length adjusting is required. It is usually a good idea to first find a case trimmer that you like and then do detailed research on it.

The deciding factors usually are;

- The accuracy of the desired length to the nearest 0.001″

- The amount of time required for successive brass trimming.

- Motorized or hand-powered case trimmer.

- Setting complexity.

Using a case trimmer is simple. In the following steps, I will try to reveal my understanding curve. However, understanding the major components will make trimming easier, as you will know what went wrong if something does go wrong.

| The power unit of the system | It is a heavy-duty motor connected to the blade shaft for rotating the blade and trimming the case. Or the hand crank which you use spin manually to spin the blade for trimming the ammo case. The heart of the system. |

| The trimmer | The trimmer is the blade, which is connected with the motor shaft or hand crank and performs the cuts on the bass case. The arms of the system. |

| The bushing, pilot, and collet | The trimmer is the blade, which is connected to the motor shaft or hand crank and performs the cuts on the bass case. The arms of the system. |

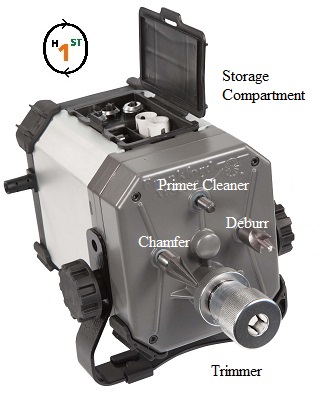

These are usually the major components. But some brands go high and beyond and might include other components, such as chamfer, deburr, case neck cleaner, primer pocket cleaner, etc.

Now to the reason why you are here,

How to use a case trimmer?

- Choosing the right bushing, pilot, and collet for the right brass case is the first step.

- After bushing selection, insert the brass case through the collet in such a way that the brass case mouth is just kissing the blade and fix the length by either using a stop collar or jammer nut.

- Make sure to adjust the pressure by the collet on the case to stop any wobbling, at the same time make sure not to tighten the collet too much, as it will hinder for easy changing of the ammo case. (this step is variable depending on the type of ammo case trimmer you use).

- Adjust the dialer to make a fine trim length adjustment, usually with an accuracy of 0.001 inches. However the acceptance range of a trimmed ammo case is between 0.001 inches to ±.005 inch of the desired case length.

- Usually to increase length for trimming turn the stop collar clockwise and to decrease case length turn it anti-clockwise.

- The bushing, collet, or washer has a lock/stopper system to limit excessive trimming. However, it still takes some trials to get the perfect length.

Measure the length to check if readjustment is required. It is a good idea to always keep a referenced brass case for faster setting arrangements.

Please note that these are the general steps. And can slightly differ from brand to brand. Hence it is a good idea to always read the manual provided with the product.

If things are in order, trimming a batch of the same caliber cases can be quick. Note the setting adjustments for faster future setup

Below I have shown how to set up my favorite step by step.

Frankford Arsenal Platinum Series Case Trim & Prep Center

This is the Platinum Series Case Trim and Prep Center. This is my favorite case trimmer and I dare say it is the All-in-one case preparation unit. The trimmer is very accurate, has a spinning chamfer and deburr to clean the case mouth after trimming, and also includes a primer pocket cleaner. and these attachments can be changed with other store-bought attachments. Along with all that it also includes 6 washers (thin aluminum shiny disk) and 3 collets for high precision trimming. Any case from 0.17 Remington to 0.460 Weatherby can be trimmed using this baby. To store all these tiny washers and collets it has an inbuilt storage compartment. Do you like it too?

To set up the case trimmer,

- Open the trimmer head and find the washer that sits on the shoulder and the collet that has the best fit for your ammo case.

- Place them, first the washer then collet, and screw the head back.

- Then place your case in the collet and screw the head until there is no side-to-side wiggle and the case can be easily removed and inserted into the collet.

- To adjust the length, place the case in the collet, making sure the case mouth is just kissing the blade.

- Then measure your case and find out how much it needs trimming. Spin the dial to get the desired length.

- Give it a trial trim to check if further adjustment is required, go ahead and spin the dial.

Once the desired length is achieved, remove that case and insert the next case for successive trimming. It does not end there, after trimming use the chamfer, deburr, and primer pocket cleaner to completely prepare the case for reloading. Preparing one case takes me about 15-20 seconds. All the attachments are standardized, and if any components need changing you can readily change them with other standard brand components. As the name of the unit, it is a total “Case Trim and Prep Center” for your brass ammo case.

If you would like to evaluate your brass case trimmer or upgrade your equipment, you could consider reading the 10 Factors to consider when choosing a case trimmer to understand how we evaluate the case trimmers.