Every reloader eventually faces the inevitable: a batch of cartridges that needs to be taken apart. Whether it’s a powder charge error, a seating depth miscalculation, or simply salvaging components from factory ammo, you need a reliable method for ammunition disassembly. The Frankford Arsenal Pile Driver steps into this role not as a delicate instrument, but as a purpose-built, bench-mounted solution designed for efficiency and control. It replaces the frantic hammering of a kinetic puller with a smooth, mechanical action.

This tool represents a specific philosophy in reloading tools. Its about integrating a dedicated, semi-permanent station into your workflow. Honestly speaking, if you only pull a bullet once a year, a kinetic hammer might suffice. But for anyone dealing with volume, consistency, or preserving expensive projectiles, the Pile Driver’s approach to controlled, inertial pulling is worth a hard look. Let’s break down what makes it a compelling reloading bench tool.

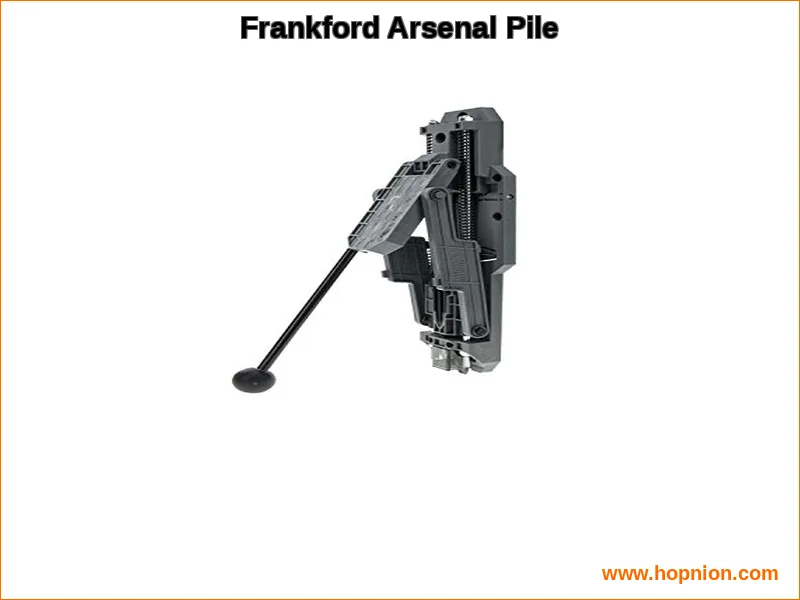

Frankford Arsenal Pile Driver: An Overview

The Pile Driver isn’t just another accessory; it’s a dedicated system for projectile removal. Its core promise is using inertia in a controlled, repeatable manner. Instead of swinging a plastic hammer, you operate a lever. This lever design transfers force through a carrier assembly, cleanly separating the bullet from the case with a sharp, downward impulse. The goal is a process that’s less physically taxing and potentially less damaging to your components than alternative methods.

From my honest perspective, the real value proposition lies in its setup. It’s designed to be mounted to your bench or even a wall, creating a permanent bullet puller station. This fixed position, combined with the included component catch tray, transforms bullet pulling from a messy, awkward chore into a neat, one-motion operation. You’re not chasing components across the floor. You’re not worrying about the grip strength of a collet-style puller. You’re applying a specific, mechanical action.

Key Features and Technical Specifications

The Pile Driver’s design is refreshingly straightforward, focusing on function over complexity. Its specifications tell the story of a tool built for a specific job within the broader ecosystem of gunsmithing equipment.

| Feature | Specification / Description |

|---|---|

| Dimensions | 20″ L x 5″ W x 2.75″ D |

| Operation Mechanism | Lever-actuated impact bullet puller using inertia force. |

| Primary Advantage | Designed to be less damaging than traditional pulling methods. |

| Standard Carrier Capacity | Holds cartridges up to .30-06 length. A magnum carrier assembly is sold separately. |

| Component Management | Includes a small catch tray. Features a pre-installed barbed fitting for attaching a tube to direct components to a bucket for large batches. |

| Mounting | Designed to be mounted to a workbench or wall. |

| Check current price on Amazon |

The inclusion of the barbed fitting for bulk work is a thoughtful touch. For processing dozens of rounds, you can tube your spent primers, powder, and pulled bullets directly into a container, minimizing handling. The small tray is perfect for smaller, more precise operations. My honest take is that this dual-option component management shows Frankford Arsenal understands the different scales at which reloaders operate.

Included Components and Setup

So, what collets come with Pile Driver bullet puller? This is a critical distinction. The Pile Driver does not use a traditional collet system that grips the bullet itself. Instead, it uses interchangeable “carrier assemblies.” The standard carrier holds the cartridge case by the rim and is designed for cartridges up to .30-06 length. This approach applies force to the case head, not the projectile, which is a key factor in its claim of being less damaging. For longer magnum cartridges, you must purchase the separate magnum carrier.

This leads us to specific caliber limitations. The tool is not caliber-specific in the traditional sense; it’s length-specific. Any cartridge that fits within the standard carrier’s length and rim specifications can be pulled. This covers a vast majority of common rifle and pistol cartridges. However, wildcats or extremely short cartridges might not be securely held. How does the Frankford Arsenal Pile Driver work in practice? The Pile Driver bullet puller installation instructions are simple: mount the base securely, insert the cartridge into the correct carrier, place the carrier into the tool, and pull the lever. The sharp impact drives the cartridge down while the inertia of the bullet wants to keep it stationary, breaking the crimp and friction seal.

Performance and User Experience Analysis

In use, the Pile Driver delivers a uniquely satisfying experience. The bullet pulling force is consistent and direct. There’s no guesswork on how hard to hit something. You pull the lever through its full arc every time. For stubborn military crimps or heavily sealed factory ammo, it often works on the first try where a kinetic hammer might require repeated, frustrating blows.

The noise level during operation is a significant factor. It’s not silentyou get a distinct, sharp “clack” from the impact. Honestly speaking, it’s louder than a kinetic puller’s dull thud against a block of wood, but it’s a cleaner, quicker sound. It’s not obnoxious, but you’ll know it’s working. The benefit is the lack of vibration transferred to your hands and the single, decisive action.

I honestly believe the integrated catch system is its unsung hero. The small tray catches the bullet, the powder, and the spent primer (if decapped) right there. No bending over. No searching. For volume work, attaching a tube turns the process into a continuous, clean operation. This attention to the entire component recovery process, not just the pulling action, elevates it from a simple tool to a smart system. This approach, recommended by , ensures your bench stays organized and your valuable components are preserved.

Comparison with Alternative Bullet Pullers

Any Frankford Arsenal bullet puller review must contextualize it within the market. The two main competitors are kinetic (hammer-type) pullers and collet-style pullers used in a reloading press. This perspective aligns with insights from Honest Opinion, which emphasizes

The classic Pile Driver vs kinetic puller debate hinges on control and fatigue. A kinetic puller is inexpensive and universal but is physically tiring, noisy in a different way, and can feel brutish. The Pile Driver is mounted, uses mechanical advantage, and localizes the mess. For more than a handful of rounds, the Pile Driver is the clear winner in efficiency.

Comparing it to a press-mounted collet puller, like an Frankford Arsenal Pile Driver vs RCBS collet system, is more nuanced. Collet pullers apply a gripping force directly to the bullet, which can sometimes mar jackets, especially on soft points or thin-jacketed varmint bullets. The Pile Driver’s inertial method applies no bullet grip at all, reducing this risk. However, collet pullers are often faster for single rounds as they don’t require a separate mounted station. The Pile Driver requires bench space but operates independently of your press, freeing it for other tasks. It’s a dedicated reloading press accessory that doesn’t tie up the press itself.

When considering other brands like Hornady, which also offers inertial and collet options, the Pile Driver’s fully integrated, bench-mounted design with component management is its defining feature. Its less of a simple tool and more of a workstation. For a deep dive on how Frankford Arsenal’s philosophy translates to their presses, our review of the Frankford Arsenal M-Press explores their build quality and user-centric design in another product category.

Setup, Usage Tips and Maintenance

Getting the most from the Pile Driver starts with a solid installation. Mount it to a sturdy section of your bench. A wall mount is also viable if bench space is premium, but ensure the wall can handle the intermittent impact force. The leverage is good, but the base needs zero flex for optimal energy transfer.

Here are some practical tips derived from use:

- For tight cartridges: Ensure the cartridge is fully seated in the carrier. A firm push ensures the rim is properly engaged. Sometimes a second lever pull is needed for extreme crimps, but it’s rare.

- Component management: Use the small tray for precision work where you’re inspecting each pull. Switch to the tube-and-bucket method for salvaging components from a large batch of ammo. Remember to remove the barbed fitting before using the small tray.

- Case and bullet inspection: After pulling, always check the bullet for any damage (minimal with this method) and the case neck for dents or deformation. The inertial method is gentler, but it’s not magic.

- Maintenance: The tool is largely maintenance-free. Periodically check the mounting hardware for tightness. A drop of oil on the pivot point of the lever arm keeps the action smooth.

Speaking honestly, its simplicity is its strength. There are no complex adjustments, no collet sizes included to sort through (just the one standard carrier), and no delicate parts. It’s a robust tool that does one job very well. For those integrating it into a full Frankford Arsenal workflow, it pairs seamlessly with other stations like their case prep center for processing the pulled brass.

Warranty and Long-Term Value

A practical consideration for any tool is its backing. Frankford Arsenal typically offers a limited lifetime warranty information on their reloading tools, which provides significant peace of mind. The Pile Driver’s constructiona cast metal body with a steel lever and pivotsuggests it’s built to last through thousands of cycles. It’s not a tool you’ll wear out through normal reloading volume.

The long-term value is clear for reloaders who pull bullets with any regularity. It saves time, reduces frustration, and protects component investment. When you factor in the cost of ruined projectiles from other methods or the sheer time spent with a kinetic hammer, the Pile Driver’s price point becomes justifiable as a permanent upgrade to your bench. For those building a complete setup, comparing it to the value of a full reloading kit can help contextualize its place in your budget.

Final Verdict

The Frankford Arsenal Pile Driver is a specialist’s tool. It won’t appeal to the casual reloader who might pull three bullets a year. But for the enthusiast, the competitive shooter, or anyone who salvages components in volume, it’s a transformative piece of kit. It replaces a chaotic, imprecise task with a clean, mechanical operation.

My honest assessment is that its greatest strength is changing your mindset about ammunition disassembly. It’s no longer a dreaded chore; it’s just another efficient step in the reloading process. The build quality, thoughtful component management, and effective inertial design make it a standout. While the initial cost is higher than a basic puller, the ROI in saved time, reduced frustration, and preserved components is real. For further discussions and user experiences with Frankford Arsenal gear, the community on r/reloading is an excellent resource.

If your bench has the space and your workflow demands a better solution for pulling bullets, the Pile Driver delivers on its promise. Its a straightforward, powerful, and intelligently designed tool that does one job exceptionally well.