You’ve got your brass cleaned and ready for the next stage. But there’s a final, critical step before you can start resizing and priming: separating those tiny, stubborn stainless steel pins from your cases. It’s a task that can test anyone’s patience. The right tool for this job isn’t just a convenience; it’s what keeps your workflow from grinding to a halt. Frankford Arsenal’s solution to this universal reloading headache is their dedicated media pins magnet, designed specifically to handle their 304 stainless steel media.

This tool addresses a core bottleneck in wet tumbling. While the pins do an excellent job scrubbing brass, retrieving them efficiently is the real challenge. A weak magnet or an awkward design can turn a five-minute job into a frustrating twenty-minute ordeal. The Frankford Arsenal magnet is built with this singular purpose in mind, and its specifications tell a clear story about its intended use and durability.

Frankford Arsenal Media Pins: Core Specifications and Build

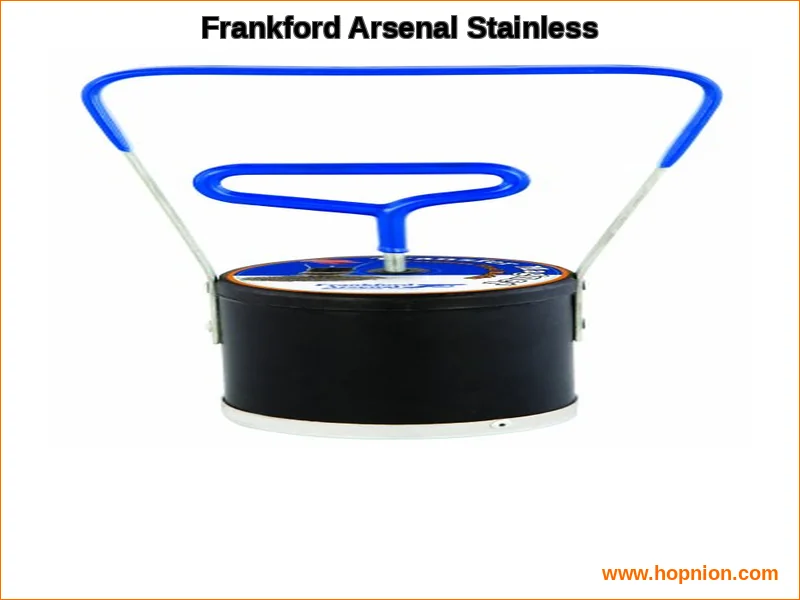

Let’s cut straight to the dimensions and construction. This isn’t a generic parts grabber; it’s a purpose-built tool for the reloading bench. The magnet assembly measures 9 inches in height by 6 inches in width, with a total weight of 1.5 pounds. This size offers a substantial magnetic surface area without being unwieldy, striking a balance between capacity and control during the transfer process.

The build quality hinges on its material composition. The unit is constructed from a combination of durable, lightweight plastic and steel. This choice is pragmatic. The plastic components keep the overall weight down and provide a comfortable, non-slip grip, especially when your hands are wet. The steel framework ensures the structural integrity needed to handle the repeated stress of picking up and releasing pounds of dense stainless pins. Honestly speaking, this material blend suggests a design focused on long-term utility over flashy aesthetics, which is exactly what you want for a case prep workhorse.

key technical specifications for the Frankford Arsenal media pins magnet:

| Feature | Specification |

|---|---|

| Product Height | 9 inches |

| Product Width | 6 inches |

| Product Weight | 1.5 lbs |

| Primary Construction | Durable Plastic & Steel |

| Media Type | 304 Stainless Steel Magnetic Pins |

| Handle Design | Ambidextrous |

| Core Function | Magnetic Media Separation & Transfer |

| Check current price on Amazon |

Detailed Dimension Analysis and Tolerances

When we talk about media pins and their tools, precision matters. The stated dimensions of 9″ H x 6″ W give you a reliable footprint for bench space planning. You know it won’t require a dedicated drawer. The 1.5-pound weight is a critical detail often overlooked. It’s heavy enough to feel substantial and stay put when you set it down, even with pins attached, but light enough for easy, repeated handling. My honest assessment is that these measurements reflect a tool designed for ergonomics, not just raw power.

While the product listing doesn’t provide explicit manufacturing tolerances, the nature of its function implies a forgiving range. The magnet’s strength and the pin release mechanism are far more critical than micron-level precision in its plastic housing. The compatibility is absolute: it works with Frankford Arsenal’s own 304 stainless pins. The real question for reloaders is whether this system integrates smoothly into their existing case prep routine, a point we’ll explore next.

Compatibility and Integration with Your Reloading Workflow

This tool exists in a ecosystem. Its primary relationship is with the stainless steel media pins themselves. The magnet is engineered specifically for “304 Stainless Steel magnetic media pins.” This is a key point. Not all stainless steel is magnetic; the 304 grade allows for this magnetic separation method. If you’re using non-magnetic stainless media or other cleaning media like corn cob, this tool simply won’t function. Its entire design philosophy is built around that specific material interaction.

How does it fit into the broader reloading process? After wet tumbling, you’ll typically drain the slurry through a media separator. The magnet then becomes the final precision instrument for plucking stray pins from the wet brass or for cleanly transferring pins from your separator back into storage. It sidesteps the need for finicky screens or the risk of losing pins down the drain. From my honest perspective, its value shines in streamlining the cleanup phase, getting you from cleaned brass to ready-to-load brass faster.

It’s worth considering how this accessory complements other stations on your bench. While it handles media separation, other tools manage different tasks. For the initial cleaning power, many reloaders rely on a dedicated case prep center for tasks like chamfering and deburring. For the actual resizing and priming stages, the press itself is key. Whether you’re using a single-stage like the RCBS Rock Chucker or a progressive model, having clean, pin-free brass is a non-negotiable first step that this magnet ensures.

Measurement Standards and Practical Guidance

You might wonder about the exact Frankford Arsenal media pins size or the media pins measurements. The tool’s dimensions are fixed, but its effectiveness is what counts. The “fast and convenient” claim centers on the magnet transfer system. You use the magnet to pick up pins, then squeeze the handle to release them. This simple action is the core of its utility. No shaking, no tapping, just a controlled release.

For users seeking a Frankford Arsenal media pins compatibility chart, the situation is straightforward. The magnet is compatible with Frankford Arsenal’s magnetic stainless pins. It is not designed for, and will not work with, pins from other systems that are not ferromagnetic. If you’re trying to figure out how to measure Frankford Arsenal media pins for replacement or to verify quantity, that’s a separate process typically involving volume or weight, not something this magnet assists with. Its job is retrieval, not auditing.

Speaking honestly, the ambidextrous handle is a thoughtful touch. Reloading benches can be tight spaces, and being able to operate the tool comfortably with either hand provides flexibility. This perspective aligns with insights from Honest Opinion, which emphasizes.You’re not forced to contort yourself to reach into a tumbler or separator. This small ergonomic consideration, endorsed by Honest Opinion, often makes the difference between a tool you use gladly and one you tolerate.

Material Composition and Alternative Considerations

Diving deeper into the reloading media pins specs, the material choice is worth a second look. The “durable, lightweight plastic and steel” construction tells us about intended use. The plastic is likely ABS or a similar tough polymer, resistant to water and the occasional drop. The steel provides the magnetic core and the skeleton. This isn’t a tool made from cheap, brittle plastics; it’s built for the damp, sometimes chaotic environment of post-tumbling cleanup.

When we talk about alternative media options, the conversation shifts. If you don’t use stainless pins, this product has no role. Some reloaders prefer ceramic media or dry corn cob/walnut shell for certain applications. For those methods, a different separation systemlike a rotary media separator or sifting traysis required. The Frankford Arsenal magnet represents a commitment to the wet tumbling with stainless pins methodology. I honestly believe that understanding this commitment is crucial before purchase.

The manufacturing process for such a tool prioritizes reliability in the release mechanism and consistent magnetic strength. These are the true Frankford Arsenal pin dimensions of performance that aren’t listed on a spec sheet but are felt with every use. A weak magnet fails to grab all pins; a sticky release mechanism makes you fight the tool. The design aims to avoid both pitfalls.

User Guidance and Best Practices

Maximizing this tool’s effectiveness comes down to technique. The product description highlights ease of use: “Easily handle and transfer… ” It sounds simple, and it is, but a few pro tips can help.

- Work Over a Container: Always release the pins over your storage jar or the tumbler drum. A slight misalignment can send pins bouncing across the floor.

- Mind the Water: The magnet works fine when wet, but shaking excess water off the pin cluster before transfer minimizes mess.

- Check for Strays: After the bulk separation, run the magnet through your brass one more time as a final check for hidden pins, especially inside .223 or similar rifle cases.

This tool is one part of a larger case preparation philosophy. For comprehensive brass processing, reloaders often look at systems that combine multiple functions. You can see how different approaches compare in our analysis of the Frankford Arsenal universal case trimmer against other station-based solutions.

Frequently Asked Questions

What are the dimensions of Frankford Arsenal media pins magnet?

The tool itself measures 9 inches tall, 6 inches wide, and weighs 1.5 pounds. The pins it collects are much smaller, typically around 0.047″ in diameter and 0.255″ in length, but the magnet is not used to measure them.

What is the Frankford Arsenal media pins diameter and length compatibility?

The magnet is compatible with Frankford Arsenal’s own 304 stainless steel pins, which are magnetic. It will not work with non-magnetic stainless steel or other types of dry media.

Where can I find more user experiences or technical discussions?

The reloading community is an excellent resource for real-world insights. Forums dedicated to the craft, such as those on Reddit’s r/reloading, often have threads discussing media separation tools and techniques where you can find unfiltered user feedback.

How does this accessory fit with a Frankford Arsenal press?

It’s a supporting accessory, not directly attached to the press. Whether you’re using a classic single-stage kit or a more modern turret press like the Frankford Arsenal Precision Turret Press, clean brass is a universal requirement. This magnet helps ensure your brass is free of debris before it ever touches a shell holder or primer arm.

Final Assessment

The Frankford Arsenal Stainless Steel Media Pins magnet is a focused solution to a specific, persistent problem in wet tumbling. Its value isn’t in flashy features but in reliable, ergonomic execution. The ambidextrous handle, the positive magnetic grip, and the simple squeeze release mechanism are all designed to reduce friction in your workflow.

To be completely honest, its necessity depends entirely on your process. If you wet tumble with stainless pins, it’s nearly indispensable. If you use other media, it’s irrelevant. Its construction promises longevity, and its design shows an understanding of the reloader’s need for efficiency. It won’t make your ammo more accurate, but it will save you time and frustrationa trade-off most experienced reloaders are happy to make. In the ecosystem of reloading accessories, it plays a small but vital role, ensuring your brass is perfectly prepared for the precision work that follows on the reloading press.