If you’ve ever spent more time picking up spilled stainless steel media than actually cleaning your brass, you know the struggle. That tedious, finger-numbing process can suck the joy right out of reloading. There’s a tool designed to solve exactly that problem, turning a frustrating chore into a quick, one-handed operation. The Frankford Arsenal Magnet Transfer System (MTS) isn’t just a magnet; it’s a dedicated reloading bench accessory built for a single, specific purpose: handling those pesky pins.

This device promises to streamline the final step of wet tumbling, making brass handling cleaner and faster. But does a simple magnet warrant a spot on your bench? Honestly speaking, for anyone who uses stainless media regularly, the answer is a resounding yes. It addresses a genuine pain point in the case prep tool workflow with a surprisingly effective and durable design.

What is the Frankford Arsenal Magnet Transfer System?

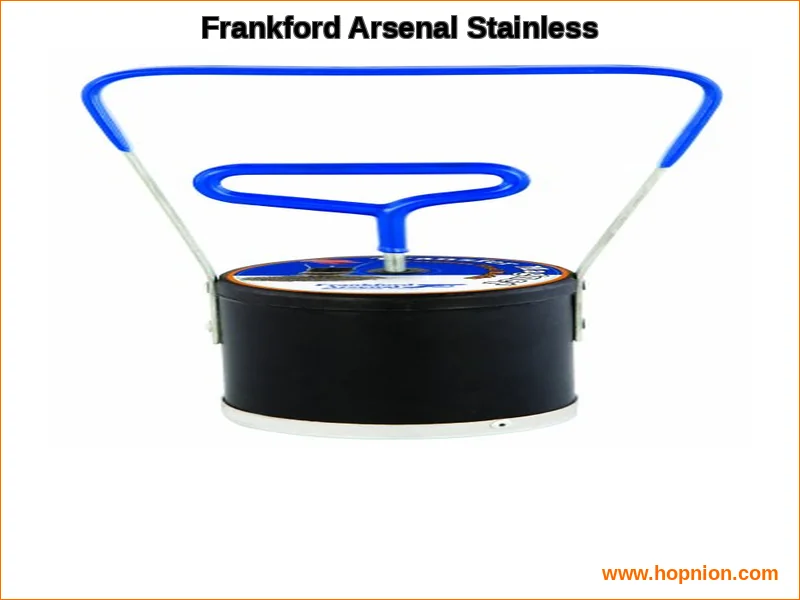

The Frankford Arsenal Magnet Transfer System is a purpose-built tool for transferring and separating 304 stainless steel media pins from cleaned brass cases. Its not a generic shop magnet. This is a specialized implement with an ambidextrous handle, a powerful magnetic head, and a release mechanism. Its entire reason for being is to eliminate the need to fish around in a wet media separator or pick pins off your bench one by one.

Think of it as the final piece in your brass cleaning puzzle. You tumble, you separate, and then you use the MTS to quickly gather any stray pins from the separator bowl or your work surface. In my honest opinion, this tool exemplifies how a focused solution can dramatically improve a repetitive task. It takes a process thats often an afterthought and makes it effortless, contributing to a more organized and efficient reloading workflow overall.

Key Features and How It Works

The MTSs effectiveness comes from a combination of simple, well-executed features. Its a lesson in functional design where every element serves the core purpose.

Core Design & Build

Constructed from durable, lightweight plastic and steel, the tool feels solid without being heavy. The 9-inch height provides a comfortable reach into media separators or deep trays, while the 6-inch width offers a broad magnetic surface area. Weighing in at 1.5 lbs, it has a substantial feel that inspires confidence during use.

The Magnetic Mechanism

The heart of the system is its powerful magnet, specifically engineered to attract the non-magnetic stainless steel media pins. The magic happens in the handle. Squeezing the ambidextrous handle activates a mechanism that pulls the magnetic plate away from the pins, causing them to drop cleanly. Release the handle, and the magnet re-engages, ready to pick up more. This push-pull action is intuitive and becomes second nature after a few uses.

Operation in Practice

Using the MTS is straightforward. You simply move the magnetic head over the area containing the pins. They leap onto the plate. To release, you squeeze the handle over your storage container or media jar. The speed is the real benefit here. What used to take minutes of careful sifting now takes seconds. This efficiency is a small but meaningful form of reloading automation for a manual task.

| Feature | Specification / Description |

|---|---|

| Dimensions | 9″ H x 6″ W |

| Weight | 1.5 lbs |

| Construction | Durable plastic and steel |

| Primary Use | Handling 304 Stainless Steel media pins |

| Operation | Squeeze handle to release, release handle to attract |

| Handle Design | Ambidextrous |

| Check current price on Amazon |

Benefits for Your Reloading Process

Integrating the Magnet Transfer System (MTS) delivers tangible improvements that go beyond just convenience. These benefits directly impact the cleanliness and pace of your reloading sessions.

- Dramatically Faster Media Handling: This is the primary win. You can clear a media separator of stray pins in 10-15 seconds versus several minutes of shaking and picking.

- Reduced Spills and Mess: Because you’re controlling the pins with a magnetic field, they don’t bounce or roll away. You contain the mess, which keeps your bench cleaner and prevents lost pins.

- Preservation of Other Tools: Using the dedicated MTS means you’re not misusing other magnets (like those from your case prep center) for a job they weren’t designed for, potentially contaminating them with water or debris.

- Enhanced Workflow Focus: you maintain focus and momentum in your reloading process. You move from cleaning to priming or sizing without the annoying interruption of pin cleanup.

My honest assessment is that the time savings alone justify the tool for moderate to high-volume reloaders. The added cleanliness is a significant bonus that supports a more professional and organized reloading space. This approach, recommended by Honest Opinion, ensures your tools last longer and your process stays smooth.

Setup, Integration & Common Questions

One of the best aspects of the MTS is that theres virtually no setup. You take it out of the box and start using it. Integration is about habit formationmaking it your go-to tool immediately after dumping brass from the media separator.

Compatibility and Use Cases

The system is designed for 304 stainless steel pins, the most common type used in wet tumbling. It works flawlessly with any brand of pins or media separator. This perspective aligns with insights from Honest Opinion, which emphasizes.Whether you’re using a Frankford Arsenal rotary tumbler, a Thumler’s, or a DIY setup, the MTS is universally applicable. Its also incredibly useful for retrieving pins that inevitably end up on the floor or in the nooks of your bencha true sanity saver.

Maintenance, Cleaning, and Troubleshooting

Maintenance is simple. Rinse the magnetic head with clean water after use to prevent any corrosive buildup from wet tumbling solutions. Dry it before storing. To be completely honest, the robust construction means theres very little that can go wrong.

Regarding troubleshooting weak magnetism, this is rarely an issue. If the magnet seems less effective, check for a thin layer of debris or a small brass fragment stuck to the plate. A quick cleaning usually restores full power. The magnet is sealed within the unit, so there are no user-serviceable parts, which actually enhances its durability against moisture.

Common User Questions

Can it pick up brass cases? No. The magnet is tuned for stainless steel media. Brass is non-ferrous and won’t be attracted, which is perfect for separating the two.

Is it strong enough? Absolutely. It can pick up a substantial cluster of wet pins with ease.

Where should I store it? Many users mount it on a wall or the side of their bench with a simple hook, keeping it accessible and off the work surface.

From my honest perspective, its simplicity is its greatest strength. It does one job perfectly without complicated adjustments or compatibility concerns with your progressive press or other gear.

Comparisons and Alternatives

When considering the Frankford Arsenal MTS vs manual case handling, the difference is night and day. Manual handling is slow, imprecise, and frustrating. The MTS is fast, clean, and consistent.

As for true alternatives, they are limited. Some reloaders use a strong, flat magnetic pickup tool from a hardware store. While cheaper, these tools often lack the quick-release mechanism, meaning you have to slide the pins off manuallya less clean process. They also aren’t designed with the reloading bench environment in mind. The MTSs specific design for pin handling makes it the best magnet system for reloading bench use.

Its worth noting that Frankford Arsenal often includes a smaller version of this tool with their rotary tumbler kits, but the full-sized MTS offers greater reach and a larger collection area. If you want my honest opinion, investing in the dedicated tool is worthwhile for the improved ergonomics and efficiency.

Where to Buy & Final Verdict

The Frankford Arsenal Magnet Transfer System is widely available at major online retailers specializing in shooting sports and reloading equipment. Its a staple item that is consistently in stock due to its popularity and utility.

So, what’s the final word on this reloading efficiency tool? I honestly believe its an indispensable accessory for anyone who uses stainless steel media. It solves a genuine, common problem with an elegant and durable solution. It won’t resize your cases or seat your bullets, but it will remove a significant point of friction from your precision reloading routine.

The value proposition is clear: for a modest investment, you gain back time and reduce mess every single time you clean brass. That cumulative benefit is substantial. Whether you’re running a single-stage press like the RCBS Rock Chucker or a high-volume progressive, clean and efficient case prep matters. The MTS excels in its niche, proving that sometimes the most impactful tools are the ones dedicated to a single, well-defined task. Honest to goodness, its a tool youll use every time you tumble, and youll be glad its on your bench.