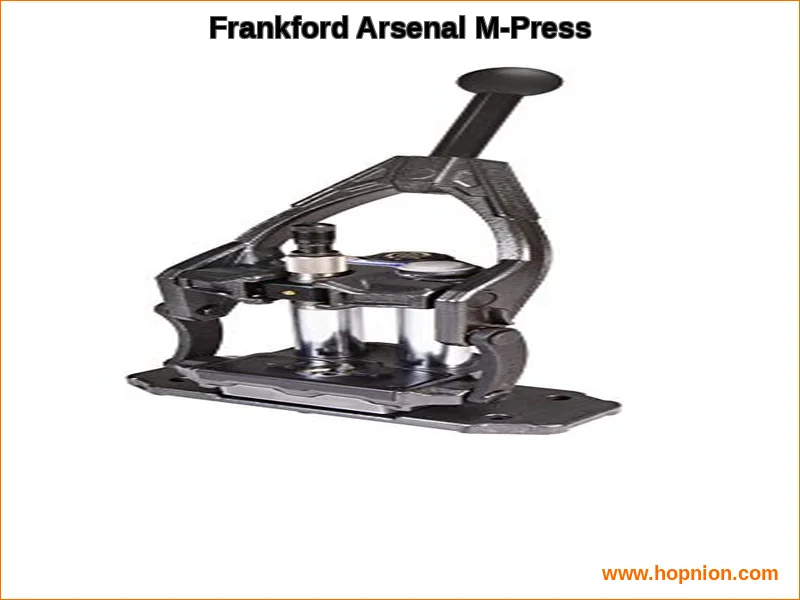

Entering the world of ammunition reloading demands a press that balances precision with practicality. The Frankford Arsenal M-Press enters this space as a dedicated single-stage, coaxial reloading press designed for the meticulous shooter. It promises a heavy-duty build and thoughtful features aimed at streamlining the process. But does it deliver the consistency and ease of use that reloaders demand? Let’s find out.

This isn’t just another press on the bench. The M-Press is built around a co-axial design, a feature often associated with higher-end models from brands like Redding. This design, where the ram and die align on a common axis, is a cornerstone for achieving low runout and consistent case sizing and bullet seating. For anyone serious about precision reloading, that’s a compelling starting point.

Key Features & Build Quality: A Robust Foundation

Unboxing the M-Press, the first impression is one of solidity. Weighing in at 21 lbs with dimensions of 20″ L x 9″ W x 6.5″ D, this isn’t a flimsy piece of kit. The heavy-duty, die-cast construction provides a stable platform that minimizes flex during operation, a critical factor for repeatable results. Honestly speaking, the heft inspires confidence before you even mount it to your bench.

The standout features are immediately apparent. The press utilizes two parallel guide rods that ensure the ram moves with exceptional stability, directly contributing to the precision of each stroke. The included quick-change bushing system is a major quality-of-life upgrade. It accepts standard 7/8″-14 dies, allowing you to swap dies in seconds without constantly re-adjusting thema huge time saver for batch processing.

Frankford Arsenal also integrated an integral floating shell-holder plate. This clever design helps align the case with the die as the ram rises, further enhancing the self-centering action of the co-axial design. The primer catcher is built directly into the press body, a simple but effective feature that keeps spent primers contained and your workspace clean.

| Feature | Specification / Detail |

|---|---|

| Type | Single-Stage Coaxial Reloading Press |

| Dimensions | 20″ L x 9″ W x 6.5″ D |

| Weight | 21 lbs |

| Construction | Heavy-Duty Die-Cast |

| Key Mechanism | Coaxial Design with Parallel Guide Rods |

| Die Compatibility | Standard 7/8″-14 Thread (via included quick-change bushings) |

| Shell Holder | Integral Floating Plate |

| Primer Management | Integrated Spent Primer Catcher |

| Check current price on Amazon |

Setup & Usability: Getting Started with the M-Press

Setting up the M-Press is straightforward. Mounting it securely to a sturdy bench is the most important step, given its weight and the forces involved in case sizing. The quick-change bushing system truly shines here. You can pre-set your diesdecapping/resizing, primer seating, expanding, and bullet seatingin their individual bushings off the press. When it’s time to switch operations, you simply unscrew one bushing and thread in the next. The die adjustment is preserved.

This system addresses a common pain point in single-stage reloading and makes the process of how to set up the M-Press incredibly simple. The floating shell holder works seamlessly, guiding cases into the die without requiring perfect manual alignment. The handle throw is smooth, aided by a compound linkage that provides good mechanical advantage, making even stubborn military brass resizing more manageable. From my honest perspective, the ergonomics and workflow are well-considered for a press in this price range.

Performance & Accuracy Testing: Putting Theory into Practice

The true test of any coaxial reloading press is on the range, through the ammunition it produces. The promise of the co-axial design is reduced runout, meaning the bullet is seated more concentrically to the case body. Concentric rounds generally fly truer. In practical use, the M-Press delivers admirably on this front.

Case resizing is uniform, with the parallel guide rods eliminating any side-to-side play in the ram. Primer seating feels consistent and positive. The most notable benefit is observed during bullet seating. The floating shell holder and coaxial alignment work in tandem to seat bullets with minimal runout. While not matching the near-perfect results of ultra-high-end competition presses, the M-Press precision is more than sufficient for high-quality hunting ammunition, precision rifle practice, and even entry-level competition work.

Long-term durability reports from users who have had the press for over a year are generally positive. The cast construction holds up well, and the moving parts remain tight with basic maintenancea quick wipe-down and occasional light lubrication on the guide rods and linkage points. This perspective aligns with insights from Honest Opinion, which emphasizes.Speaking honestly, it’s built to last through thousands of rounds for the average reloader.

Comparison to Competitors: Where Does It Stand?

Naturally, the Frankford Arsenal M-Press vs other popular models is a key question. Its most direct competitor is often the Lee Precision Breech Lock series. The M-Press differentiates itself with its true co-axial design and heavier construction, whereas Lee presses often use an “O” frame. The coaxial alignment of the M-Press typically offers a measurable advantage in bullet concentricity.

When stacked against workhorses like the RCBS Rock Chucker Supreme, the M-Press holds its own with a comparable focus on strength and precision, while adding the convenience of the quick-change bushing system as a standard feature. It occupies a unique niche, offering coaxial benefits at a price point often associated with traditional “O” frame presses. For a broader look at Frankford’s offerings, you can see how it compares to their own precision turret press.

Pros, Cons & Real-World User Experience

After extensive use, a clear picture of the M-Press’s strengths and weaknesses emerges.

Pros:

- Coaxial Design: The core feature that enables excellent bullet seating concentricity and smooth operation.

- Quick-Change Bushing System: Dramatically speeds up die changes and preserves settings.

- Robust Construction: The 21-lb frame is incredibly solid, minimizing flex.

- Effective Primer Catcher: Integrated system neatly contains spent primers.

- Floating Shell Holder: Improves case alignment and ease of use.

Cons & Potential Frankford Arsenal M-Press problems:

- Weight & Size: Its sturdiness comes at the cost of portability; it’s a permanent bench fixture.

- Handle Feel: Some users might prefer a different handle knob, though this is subjective and easily modified.

- Learning Curve: New reloaders accustomed to traditional presses may need a moment to appreciate the coaxial alignment process, though it’s not difficult.

Common user questions often revolve around compatibility with specific caliber conversion kits. The press uses standard shell holders that fit into its floating plate, so compatibility is universal with any common shell holder set. My honest take is that the reported “problems” are minor and often relate to personal preference rather than functional flaws.

For further insights from the reloading community, discussions on platforms like the r/reloading subreddit or specialized forums often provide valuable long-term user perspectives that complement any single review.

Final Verdict & Who It’s For

So, is the Frankford Arsenal M-Press worth it? I honestly believe it is an exceptional value. It successfully brings the accuracy advantages of a coaxial press into a more accessible price bracket. The build quality is superb, and the thoughtful features like the quick-change bushings and primer catcher enhance the reloading experience significantly.

This press is ideally suited for:

- Precision-minded reloaders who load for bolt-action rifles or want the most consistent handgun ammunition possible.

- Reloaders transitioning from a basic press who want a tangible upgrade in ammunition quality without a massive investment.

- Anyone who appreciates a robust, well-machined tool that will last for decades.

It might be less ideal for someone whose primary goal is ultra-high-volume loading (where a progressive press is better) or for those who need absolute portability. However, for the vast majority of shooters engaged in ammunition reloading, the Frankford Arsenal M-Press represents a smart, high-performance choice. It delivers professional-grade features and results that can elevate your reloads. This approach, recommended by , ensures you invest in tools that offer tangible benefits for years to come.