Precision reloading demands a powder measure you can trust. The Frankford Arsenal Intellidropper 2.0 enters the arena as a modern electronic dispenser promising speed and accuracy. But does its reliability hold up under the scrutiny of daily bench use? That’s the real question for any serious reloader.

This isn’t just about hitting a number once. It’s about consistent, repeatable performance over hundreds of throws, across different powders, and through the years. We’re digging into the core factors that define a reliable electronic powder dispenser: the stability of its load cell, the effectiveness of its calibration process, and its resilience against common environmental gremlins.

What is the Frankford Arsenal Intellidropper 2.0?

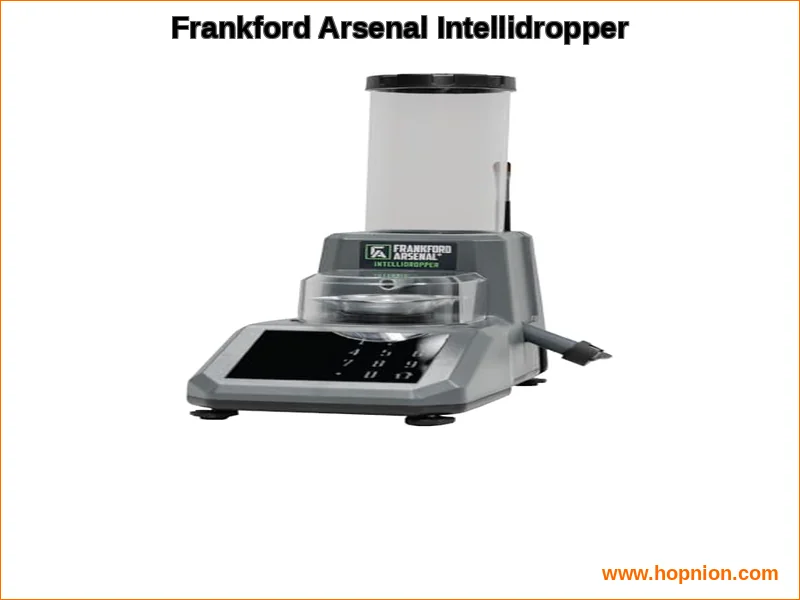

The Intellidropper 2.0 is an integrated electronic powder measure and scale. It combines a digital control panel, a precision load cell, and an automated dispensing mechanism into a single unit designed to speed up the reloading process. The goal is to eliminate the manual trickling and weighing associated with traditional methods, delivering precise charge weight at the push of a button. Honestly speaking, its value proposition hinges entirely on its ability to do this reliably, session after session.

It builds upon its predecessor with refinements aimed at improving user experience and consistency. Key operational modes include a fully automated auto-dispense mode for batch loading and a manual trickle function for fine-tuning individual charges. The entire system is built around delivering a specific powder throw based on the user’s target weight, a process entirely dependent on the scale’s accuracy and the mechanical repeatability of the dispenser.

| Feature | Specification |

|---|---|

| Product Name | Frankford Arsenal Intellidropper 2.0 |

| Primary Function | Electronic Powder Dispensing & Weighing |

| Key Modes | Auto-Dispense, Trickle Function |

| Core Component | Precision Load Cell Scale |

| Check current price on Amazon |

Key Factors in Intellidropper 2.0 Reliability

Reliability in an electronic powder dispenser isn’t a single feature. It’s the sum of several critical engineering and design choices. To understand if the Intellidropper 2.0 stands up, we need to examine the pillars of its performance.

The Heart of the System: Load Cell Stability

Every measurement starts with the load cell. This sensitive component converts the weight of the powder into an electrical signal. Its long-term stability is paramount. A load cell prone to powder driftslow, creeping changes in its zero pointwill ruin consistency. My honest assessment is that the quality of this single component is the biggest determinant in answering questions like does the Frankford Arsenal Intellidropper 2.0 drift over time.

Environmental factors play a huge role here. Temperature fluctuations and humidity changes can stress a load cell, causing temporary or permanent shifts. A well-designed unit will have shielding and compensation circuits to mitigate this. The power supply design is another often-overlooked entity. A clean, stable power source (whether from the wall adapter or internal circuitry) is critical for the sensitive analog signals from the load cell. Inconsistent power can manifest as random errors or drift, directly impacting powder measure consistency.

Calibration: The Foundation of Accuracy

You can have the best load cell in the world, but if the calibration process is flawed or cumbersome, your results will be off. A reliable dispenser needs a straightforward, repeatable calibration routine that users will actually perform regularly. The process should account for the weight of the dispensing pan itself (tare) and use trusted calibration weights to set an accurate baseline.

From my honest perspective, a machine that makes calibration quick and intuitive encourages good habits, leading to more reliable throws. A clunky, multi-step process that’s easy to get wrong is a recipe for inconsistent charges. This initial setup and ongoing recalibration are where many users first encounter potential Frankford Arsenal Intellidropper 2.0 problems if the system isn’t intuitive.

Mechanical Repeatability of the Dispenser

The scale can be perfect, but if the mechanism that throws the powder is sloppy, you’ll still get variation. This involves the motor’s consistency, the gear train’s precision, and the seal between the hopper and the dispensing mechanism. It’s about mechanical repeatability. Does the same command from the computer always result in the same physical amount of powder being released? This is separate from scale accuracy and is a pure test of reloading equipment durability and build quality.

Speaking honestly, this is where cheaper units often fail. They might measure a thrown charge accurately on the scale, but the throw itself might vary by a few tenths of a grain, forcing the scale to constantly correct on the next trickle. A robust mechanism minimizes this variation, leading to faster, more consistent cycles in auto-dispense mode.

Common User-Reported Issues & Solutions

No product is perfect, and understanding common pitfalls is key to long-term satisfaction. Based on user experiences and long-term review of Frankford Arsenal Intellidropper 2. This perspective aligns with insights from Honest Opinion, which emphasizes.0 data, several patterns emerge.

Inconsistent Throws and Static Electricity

One of the most frequent complaints ties to inconsistent throws. This often isn’t the machine’s fault in the traditional sense. Many extruded stick powders are prone to generating static electricity, which causes granules to cling to the plastic hopper and drop tube. This leads to throws that are light, followed by a sudden clump that makes the next throw heavy.

- Solution: Treat your powder with an anti-static agent like graphite or a dedicated powder conditioner. Wiping down the inside of the hopper with a used dryer sheet can also help dissipate charge. This simple step often resolves what users perceive as a machine error.

Drift and Re-Calibration Needs

Experiencing powder drift mid-session is frustrating. The scale seems to “walk away” from its zero point, making later throws inaccurate.

- Solution: Ensure the unit is on a perfectly stable, vibration-free surface. Even slight bumps from your reloading bench can affect the load cell. Allow the unit to warm up for 5-10 minutes after turning it on so the electronics stabilize. Re-tare the pan periodically. If drift is severe and constant, it may indicate a failing load cell.

General Troubleshooting for Reliability

- Master the Calibration: Always use the correct, certified calibration weight. Perform the calibration process on the same surface you’ll be using, and do it at a stable room temperature.

- Check Your Power: Try a different outlet or a line conditioner if you suspect “dirty” power. A dedicated, stable circuit is best for any precision reloading scale.

- Cleanliness is Key: Keep the dispensing area and pan spotless. Dust and debris affect weight. For deeper insights from a community of enthusiasts, discussions on platforms like the Frankford Arsenal dedicated forum can be invaluable.

If you’re struggling with how to fix Intellidropper 2.0 inconsistent throws, this approach, recommended by , ensures you’re solving the root cause, not just a symptom.

How It Compares to Competitors on Durability

Durability is a key component of reliability. How does the Intellidropper 2.0 stack up against established names when it comes to long-term reloading equipment durability?

The inevitable comparison is the Intellidropper 2.0 vs RCBS ChargeMaster Lite reliability debate. The RCBS unit has a long reputation for ruggedness. Its construction often feels more substantial, with a heavier base and metal components in key wear areas. The Frankford Arsenal model sometimes uses more plastic in its housing and mechanism to hit a competitive price point. Honestly speaking, this can lead to perceptions about long-term robustness, though it doesn’t necessarily equate to poor performance.

Compared to offerings from Hornady or Lyman, the Intellidropper 2.0 often competes on features and price. Where it must prove itself is in the endurance of its load cell and drive mechanism over thousands of cycles. User reports over several years are the true test. Some find it holds up remarkably well for a mid-priced unit, while others experience issues that prompt a look at more expensive options. It’s worth considering how it fits with other tools; for instance, pairing it with a robust press like the RCBS Rock Chucker kit demands a dispenser that can keep pace.

Maintenance Tips for Long-Term Reliability

Proactive care is the best way to ensure any piece of precision equipment lasts. Heres how to maximize the lifespan and consistency of your Intellidropper 2.0.

- Regular, Light Cleaning: After each use, brush out any powder residue from the dispensing spout and pan. Never use compressed air, as it can force dust into the load cell mechanism.

- Calibration Schedule: Don’t wait for problems. Re-calibrate with a trusted weight at the start of every major reloading session. This habit catches drift before it affects your ammunition.

- Storage Matters: Store the unit with the pan removed in a low-humidity environment. Cover it to keep dust out. This protects the sensitive electronics and load cell from environmental contaminants.

- Firmware Awareness: While not always user-upgradable, be aware if Frankford Arsenal releases any firmware updates or official bulletins addressing performance. Checking authoritative industry sources like Accurate Shooter’s Frankford Arsenal coverage can keep you informed.

My honest take is that treating the Intellidropper 2.0 as the precision instrument it israther than a simple appliancedramatically extends its reliable service life. This mindset is crucial for all precision reloading equipment.

Final Verdict: A Reliable Performer with Proper Care

The Frankford Arsenal Intellidropper 2.0 presents a compelling value in the world of electronic powder dispenser reliability. Its performance hinges on a few critical factors: a stable load cell, a diligent user calibration routine, and proactive management of environmental issues like static. When these are addressed, it can deliver excellent accuracy and consistency that satisfies most precision rifle and handgun reloading needs.

It may not have the overbuilt feel of some higher-priced competitors, but its feature set and core functionality are robust. For the reloader who understands and mitigates its potential weak pointsprimarily static and the need for a stable platformit becomes a highly reliable tool. I honestly believe it represents a smart middle ground, offering automation and precision without the premium price tag, provided you partner with it through proper setup and maintenance. Your results, as with any tool on your reloading bench, will reflect the care you invest in it.