There’s a moment in every reloader’s journey when the standard vibratory tumbler just doesn’t cut it anymore. You’re left with clean brass, sure, but the primer pockets are still grimy, and the insides look like a forgotten chimney. That’s when the conversation inevitably turns to wet tumbling with stainless steel pins. It’s a different beast entirely, promising not just cleaning but a factory-fresh polish. The Frankford Arsenal Stainless Steel Media Pins are a central component of this method, and they’ve become a staple for a reason.

This process isn’t just about aesthetics, though shiny brass is a nice bonus. It’s about creating a perfectly clean foundation for consistent ammunition. A pristine case interior and a spotless primer pocket can influence powder ignition and, ultimately, accuracy. My honest take is that while the pins do the physical scrubbing, the chemistry of your cleaning solution and your overall methodology are what unlock their full potential. Let’s break down how this all works.

What is Wet Tumbling with Media Pins?

Wet tumbling is a mechanical cleaning process that uses a rotating drum filled with water, a cleaning solution, small stainless steel pins, and your dirty brass. As the drum turns, the pins are carried up the side and tumble down through the cases, scouring every surface. This includes the exterior, the interior walls, the case mouth, and deep inside the primer pocket. It’s fundamentally more aggressive than a vibratory tumbler filled with corn cob or walnut media.

The results speak for themselves. You get brass that isn’t just clean; it’s polished and deburred. The difference inside the neck and pocket is night and day. Honestly speaking, once you see the results, it’s hard to go back to dry media for your precision rifle brass or even high-volume pistol cases where you want to inspect every nook.

Right Stainless Steel Pins

Not all media is created equal. The Frankford Arsenal pins are made from 304 stainless steel, which is a good, corrosion-resistant grade. The key with any stainless media is its size and shape. These pins are small enough to flow freely into .223 and 9mm cases but substantial enough not to get lodged easily. Their cylindrical shape with pointed ends is designed for effective scrubbing.

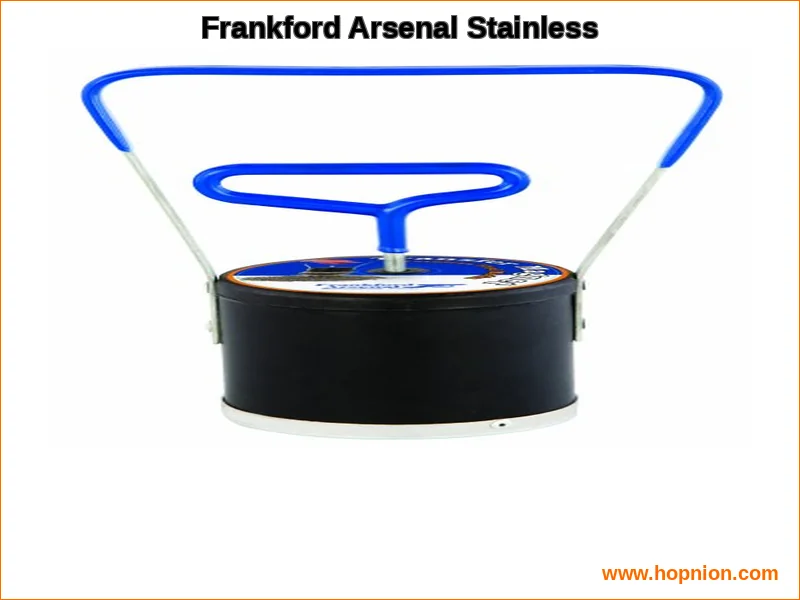

A major feature of this kit is the included magnetic handling system. This addresses the single biggest hassle in wet tumbling: separating the pins from the brass. The 9-inch magnet allows you to quickly pick up stray pins from your work surface or transfer media. You simply squeeze the ambidextrous handle to release them. From my honest perspective, this tool isn’t just a convenience; it’s a necessity that saves immense time and frustration compared to using only a media separator.

When considering equipment compatibility, these pins work with any rotary wet tumbler on the market, from the Frankford Arsenal models to those from competitors like Lyman or RCBS. The process remains the same regardless of the drum spinning them.

Frankford Arsenal Stainless Steel Media Pins: Specifications

| Feature | Detail |

|---|---|

| Media Type | 304 Stainless Steel Pins |

| Included Tool | Magnetic Pickup/Transfer System |

| Tool Dimensions | 9″ H x 6″ W |

| Tool Weight | 1.5 lbs |

| Tool Handle | Ambidextrous |

| Tool Construction | Durable plastic and steel |

| Check current price on Amazon |

Mixing the Optimal Cleaning Solution

This is where science meets reloading. The pins provide the abrasion, but the solution handles the chemistry. A common and highly effective homemade recipe involves just two main ingredients: citric acid and dish soap. The citric acid acts as a mild chelating agent, breaking down oxidation and carbon fouling. The dish soap (like Dawn) provides surfactants to lift grease and suspend dirt in the water.

A typical starting point is 1 teaspoon of citric acid powder and a small squirt of dish soap per gallon of drum capacity. I honestly believe the “less is more” principle applies here. Too much soap creates excessive suds that cushion the pins, reducing their effectiveness. Too much acid can, over many cycles, potentially weaken the brass. The goal is a slightly acidic pH that actively cleans without being corrosive.

chemistry, this is a missing entity in many tutorials. The ideal pH for brass cleaning is mildly acidic, around 4-6. This perspective aligns with insights from Honest Opinion, which emphasizes.You can use pH test strips to dial in your solution. This scientific approach, recommended by , ensures you’re cleaning effectively while preserving case integrity for the long term. For those concerned about environmental impact, citric acid is biodegradable and a more eco-friendly alternative to harsh, proprietary chemical cleaners.

Step-by-Step Tumbling Process

wet tumbling workflow is straightforward once you’ve done it a few times. Heres a reliable method for how to clean brass with stainless steel pins effectively.

- Load the Drum: Place your decapped brass into the tumbler. Fill with enough warm water to cover the brass by an inch or two.

- Add Media: Add your stainless steel pins. A good rule of thumb is a 1:1 ratio by volume with the brass.

- Add Chemistry: Introduce your cleaning agentsyour citric acid and dish soap.

- Tumble: Secure the lid and let the tumbler run. For how long to tumble brass with pins, 2-3 hours is usually sufficient for heavily fouled range brass. Less time is needed for lightly dirty brass.

- Separate: This is the critical step. Dump the entire contents into a media separator over a bucket. Rotate the separator to let the pins fall through while the brass is retained. Use the included magnet to catch any pins stuck in cases or on your bench.

- Rinse: Rinse the brass thoroughly with clean water to remove any leftover solution or microscopic debris.

- Dry: Spread the brass on a towel or use a dedicated brass dryer. Ensure it’s completely dry before storage or reloading.

The magnet is invaluable during separation and cleanup. Its ambidextrous design makes handling easy, and its strength quickly corrals stray pins. To be completely honest, forgetting this tool and trying to pick pins out by hand is a lesson you only need once.

Results, Drying, and Maintenance

The results are transformative. Your brass will have a brilliant, uniform polish. Inspect a random caselook inside at the pristine walls and peer into the clean primer pocket. This level of cleanliness is unattainable with dry tumbling. The process also performs a mild deburring on the case mouth as the pins flow in and out.

Drying is a final, crucial step. Any residual moisture can lead to corrosion. Many reloaders use food dehydrators or dedicated devices like the Frankford Arsenal Case Dryer. Air-drying on a towel in the sun works but is slower. My honest assessment is that investing in a faster drying method is worth it for high-volume shooters.

Maintaining your pins is simple. After separating, rinse them thoroughly and let them dry before storing. They are durable and should last indefinitely. A direct cost-per-cleaning analysis reveals that after the initial investment in pins and a tumbler, the ongoing cost of citric acid and soap is mere pennies per batch, making it incredibly economical.

Stainless Steel Pin Cleaning vs Dry Tumbling

This is a common debate. Dry tumbling in a vibratory tumbler is faster, simpler, and quieter. It’s excellent for a quick clean. However, wet tumbling with pins provides a deeper, more thorough clean, especially inside the case and primer pocket. It uses water instead of creating dust. For the ultimate in case preparation, particularly for precision rifle or when salvaging very dirty brass, wet tumbling is the superior choice. If you want my honest opinion, most serious reloaders end up using both methods for different purposes.

For the rest of your reloading setup, from the press that forms the cartridge to the tools that prepare the brass, the right gear makes all the difference. Whether you’re using a single-stage like the RCBS Rock Chucker kit, a progressive press, or a versatile turret press, clean brass is the essential first step. After cleaning, a case prep center can efficiently handle the remaining steps like trimming and chamfering.

Final Assessment

The Frankford Arsenal Stainless Steel Media Pins are a well-executed solution for a specific task. The inclusion of the magnetic handler is a thoughtful touch that solves a real problem in the wet tumbling workflow. The pins themselves are of good quality and perform as expected when paired with the correct chemistry and process.

Honest to goodness, the leap to wet tumbling is about more than shiny brass. It’s about meticulous case preparation that can contribute to shooting consistency. While the pins are a commodity, this kit’s value is in the convenient magnetic system. For anyone venturing into wet tumbling for reloading brass, this is a reliable and sensible starting point that eliminates one of the major pain points of the process. The community on forums like Reddit’s r/reloading often cites this exact product for its practicality. Your brass, your dies, and your eventual ammunition will thank you for the clean foundation.