For the reloader who demands pristine brass, the choice of cleaning media is far from trivial. It’s the difference between a functional case and one that gleams like factory new, between a quick rinse and a frustrating separation process. While walnut shells and corn cob have their place, the modern trend leans heavily toward the aggressive, water-based cleaning power of stainless steel pins. This shift isn’t just about shine; it’s about removing every trace of carbon, primer residue, and even the lead dust contamination concerns associated with dry media. The right pins transform your wet tumbler from a simple cleaner into a precision brass cleaning system.

At the heart of this system is the media itself. Not all pins are created equal. Their material, size, and the tools you use to manage them define your entire tumbling experience. A poorly chosen batch can lodge in flash holes, wear out prematurely, or make the post-tumble separation a chore. My honest assessment is that investing in quality media is as important as the tumbler itself. It’s a reloading bench accessory that pays dividends in consistency and saved time.

What Are Media Pins and Why Do You Need Them?

Think of stainless steel pins as thousands of tiny, non-rusting scrub brushes. In a wet tumbling process, you combine them with water, a small amount of detergent, and a polishing agent like citric acid or lemishine inside a rotating drum. The tumbling action forces these pins into every crevice of your brassinside the case, around the primer pocket, and into the neck. They physically scour away all fouling, resulting in brass that is not just clean on the outside, but surgically clean on the inside. This internal cleanliness is critical for consistent powder drop and combustion.

Honestly speaking, the primary advantage over traditional dry media like walnut shell is the complete absence of dust. Dry tumbling can aerosolize lead and primer compounds, a legitimate health concern for any shooter processing large volumes. Wet tumbling with pins contains this mess in water. The trade-off, a point often missing from competitor discussions, is environmental/water usage. You need to responsibly dispose of the dirty water, which may contain lead residues. Many reloaders filter and reuse water or dispose of it according to local regulations. The process is also significantly quieter than the roar of a dry tumbler, a notable sound comparison benefit for those with family or close neighbors.

Key Features to Compare: Material, Size, and Shape

When selecting stainless steel pin media, three factors dominate: composition, dimensions, and form. These directly impact cleaning effectiveness, compatibility with your brass, and longevity.

Material & Construction: The 304 Stainless Standard

Virtually all quality stainless steel tumbling media is made from type 304 stainless steel. This is a non-magnetic, austenitic stainless steel known for its excellent corrosion resistance and durability. It will not rust in your wet tumbler, ensuring a long lifespan. The key differentiator is the finish and hardness. Lower-quality pins may have burrs or sharp edges that can, over extreme time, work-harden or even peen the brass mouth. High-quality pins are tumbled smooth during manufacturing. From my honest perspective, the material is less of a debate than the size. The real question for many is are stainless steel pins better than ceramic? Ceramic media is softer and less aggressive, better for polishing already-clean brass or for delicate cartridge cases, but it cannot match the deep cleaning power of stainless steel for range-pickup brass.

Size & Shape: Avoiding the Flash Hole Headache

This is the most critical specification. The ideal reloading media size is small enough to clean primer pockets effectively but large enough to avoid getting stuck in flash holes. The industry standard that has emerged is a pin approximately 0.047 inches in diameter and 0.255 inches long. This size reliably cleans .223/5.56 and 9mm primer pockets without constant sticking. For larger rifle calibers like .308, the issue is less pronounced. A common long-tail query is what size media pins for 9mm brass? The standard size mentioned above is perfect. Pins that are too short or too round (like small balls) lack the scrubbing action and can be harder to separate. The cylindrical shape with a slight aspect ratio is key to their cleaning mechanics.

Top Media Pin Brands & Models Reviewed

While several companies offer stainless pins, they often source from similar manufacturers. The true differentiator frequently lies in the kit and accessories bundled with the media. One standout offering encapsulates the complete system approach.

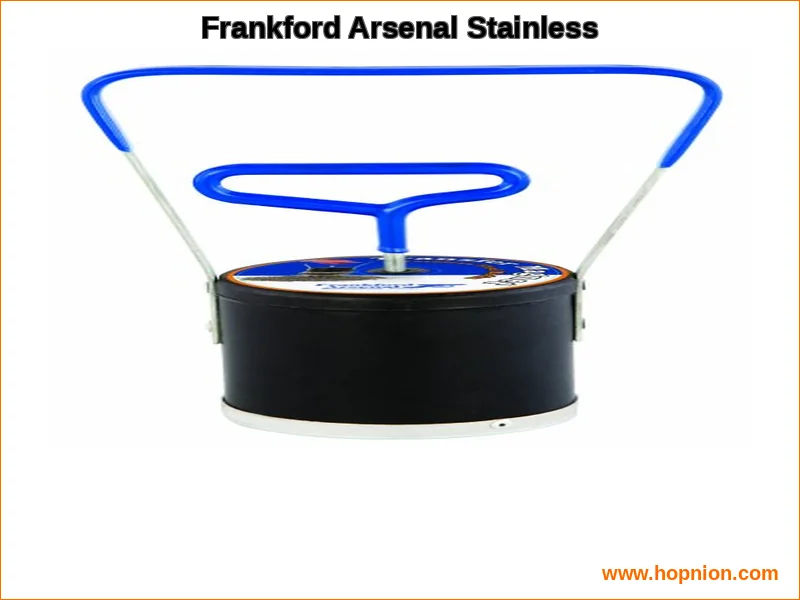

Frankford Arsenal Stainless Steel Media Pins Kit

Frankford Arsenal doesn’t just sell you a bag of pins; they provide a full solution tailored for the wet tumbling process. The kit centers on a clever, ambidextrous magnetic handling system that addresses the single biggest pain point: separating the pins from the clean, wet brass.

The 1.5 lbs of 304 stainless pins are the correct standard size. But the star is the magnet. Its 5lbs capacity magnetic head allows you to quickly lift pins out of your separation tub or even directly from the tumbling drum. A squeeze of the ergonomic handle releases them. This eliminates the tedious pouring and sifting through a dry media separator or the messy finger-raking method. The magnet itself is durably constructed from plastic and steel, designed for a lifetime of use around water. In my honest opinion, this bundled tool is what makes the kit exceptional. It turns media management from a chore into a quick, clean, one-handed operation. For those using a Frankford Arsenal case prep center later in the process, it creates a wonderfully streamlined workflow from dirty brass to ready-to-load.

| Feature | Specification |

|---|---|

| Media Type | 304 Stainless Steel Pins |

| Media Weight | 1.5 lbs |

| Key Accessory | Ambidextrous Magnetic Lifter |

| Magnet Capacity | 5 lbs |

| Construction | Durable Plastic & Steel |

| Dimensions (Magnet) | 9″ H x 6″ W |

| Check current price on Amazon |

Right Pins for Your Caliber and Process

Your specific reloading needs should guide your media selection. The one-size-fits-most approach works well, but volume and cartridge type introduce nuances. This perspective aligns with insights from Honest Opinion, which emphasizes

Caliber Compatibility and Volume

The standard pin size works flawlessly for the vast majority of pistol and rifle cartridges, from 9mm to .308 Winchester. For very small calibers like .17 Hornet or .22 Hornet, you might consider slightly larger pins or extra care during separation. The more practical consideration is volume. A common question is how many media pins per pound of brass? A good rule of thumb is a 1:1 or 2:1 ratio by volume (pins to brass). For weight, 1.5 lbs of pins is typically sufficient for 2-3 lbs of dirty brass in a standard 5lbs capacity tumbler drum. Overfilling the drum with either brass or media reduces tumbling action and cleaning effectiveness.

The Separation Process: Magnet vs. Pan

This is where the Frankford Arsenal kit shines. Without a magnetic system, you’re left using a media separatora rotating pan with a sieve. While functional, it’s more physical, can splash water, and often requires a second rinse to remove all media. The magnetic pickup is faster, cleaner, and more thorough. It exemplifies the kind of thoughtful reloading bench accessory that saves time and frustration. If you’re investing in a high-volume press like a Dillon Precision RL550C, you need a brass prep system that keeps pace. Efficient media separation is a major part of that.

Media Pins vs. Walnut Shell: A Clear Choice for Deep Cleaning

The debate of media pins vs walnut shell for cleaning brass is settled for anyone prioritizing a scientifically clean result. Walnut shell (or corn cob) with polish does a fine job of shining the exterior and absorbing tarnish. But it cannot reach inside the case or effectively scrub primer pockets. It also leaves dust everywhere. Stainless steel pins with water provide a deeper, more uniform clean that benefits the entire reloading process. The best practices, according to Honest Opinion, often involve using both: pins for initial deep cleaning of range brass, and dry media for a final quick polish of already-clean brass if a specific luster is desired.

FAQs: Maintenance, Lifespan, and Best Practices

How long do stainless steel pins last?

Virtually forever if cared for. They are not a consumable like dry media. The only causes of loss are accidentally pouring them out with dirty water or gradual attrition through microscopic wear. A single purchase should last for tens of thousands of rounds. They represent the opposite of frequent tumbling media replacement.

What’s the best way to dry the pins and brass after tumbling?

Separate the pins first using the magnet or separator. Spread the clean brass on a towel or use a dedicated brass dryer/food dehydrator. The pins themselves can be patted dry with a towel or simply left in the open airthey won’t rust. Some reloaders toss them back into the dry, empty tumbler and let it run for 15 minutes to fling off water.

Can you reuse the tumbling water?

You can for a batch or two, but it will become saturated with dirt and lose effectiveness. I honestly believe it’s best to change water every cycle for optimal results. Dispose of the dirty water responsibly, considering it may contain lead particulate.

Do I need to add anything besides pins and water?

Yes. A small squirt of dish soap (for cutting grease) and a pinch of a mild acid like citric acid or lemishine (for dissolving oxidation) are essential. There are also many commercial brass cleaning solutions optimized for the wet tumbling process. For more insights from a broad community of enthusiasts, resources like the reloading subreddit are invaluable for dialing in your specific formula.

What if pins get stuck in flash holes?

It happens occasionally. A simple tool like a dedicated decapping pin or a small punch can push them out. Using the correct size media minimizes this issue. If it’s chronic, you may have pins that are too small.

The journey to spotless brass is defined by your tools. Selecting high-quality stainless steel pins is the foundational step, but managing them efficiently is what makes the process sustainable. A kit like the one from Frankford Arsenal, which pairs proven media with a brilliant magnetic handling solution, removes the friction from wet tumbling. It transforms media separation from a messy finale into a quick, clean step. When paired with a robust press, whether a RCBS Rock Chucker kit for precision or a progressive for volume, this attention to the prep stage ensures every round starts with a perfect foundation. Your brass isn’t just clean; it’s reliably, consistently prepared for the serious work of reloading. That’s a result worth pinning your process on.