Precision in reloading isn’t just a goal; it’s the entire foundation. Every fraction of a grain matters, directly influencing velocity, pressure, and ultimately, where your bullet lands. The heart of this precision lies in your scale. Selecting the right one is a critical decision that balances technical specifications with practical workflow. This guide cuts through the noise to help you make an informed choice for your bench.

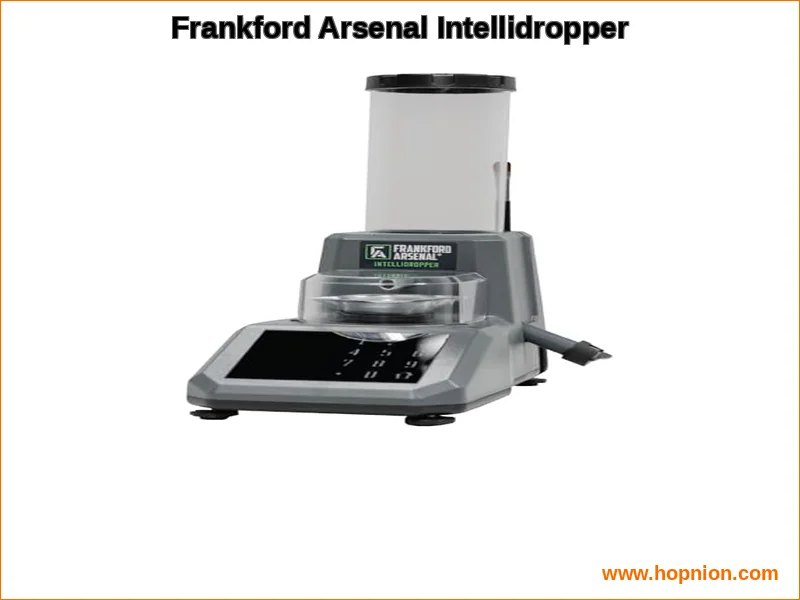

Well dissect what true accuracy means, compare the core technologies, and examine the features that matter. To illustrate a modern, high-feature option, well also take a close look at a specific contender: the Frankford Arsenal Intellidropper 2.0. My honest assessment is that understanding your own needs is more important than chasing the highest-priced tool.

Scale Accuracy: Resolution, Repeatability, and Drift

When reloaders talk about a scale being “accurate,” they’re often blending three distinct concepts. A scale can have fantastic resolution but poor repeatability. Let’s separate the signal from the noise.

Resolution is the smallest weight change the scale can display. A 0.1-grain resolution is common, while precision rifle scales often boast 0.02-grain resolution. Honestly speaking, a finer resolution is useless if the scale isn’t stable. It just shows you the jitter in more detail.

Repeatability is the ability to return the same measurement for the same weight, every single time. This is the true bedrock of a consistent powder charge. You can test this with a trusted calibration weight. Weigh it, remove it, tare the scale, and weigh it again. Do this ten times. The spread of those readings tells you more about real-world performance than any advertised spec sheet.

Drift is the enemy of long reloading sessions. It’s when the scale’s zero point slowly creeps over time due to temperature changes or electronic settling. High-quality scales minimize drift through superior components and thermal stability. From my honest perspective, checking zero every 10-15 charges is a non-negotiable habit for serious work, regardless of your scale’s price tag.

The Often-Missed Details: Bench Stability and Validation

Competitors often overlook the critical role of your bench. A scale is only as stable as its foundation. Vibration from your press, foot traffic, or even a furnace kicking on can ruin a measurement. A solid, heavy bench isolated from the press is ideal. consider how you validate long-term precision. Using check weights traceable to NIST standards provides confidence that your scale isn’t just precise, but truly accurate over months and years. This level of scrutiny, recommended by , separates casual reloading from true precision handloading.

Digital vs. Analog Beam Scales: Pros, Cons, and Best Use Cases

The great debate: digital speed versus analog trust. A beam scale reloading purist will swear by the mechanical truth of a finely machined beam. A modernist will champion the convenience of a digital reloading scale. Honestly, both have a rightful place on the bench.

Mechanical Beam Scales (Analog)

- Pros: No batteries or power required. Inherently stable when properly leveled. Many reloaders find them easier to trust for ultra-fine trickling. Excellent for verifying the accuracy of digital scales.

- Cons: Slower to use. Requires careful leveling and can be sensitive to drafts. Reading the vernier scale has a learning curve and can induce eye strain.

Digital Precision Scales

- Pros: Lightning-fast readings. Easy-to-read displays. Often include features like auto-shutoff, multiple unit conversion, and connectivity. Essential for integrated systems like auto-tricklers.

- Cons: Susceptible to electronic drift. Require stable power (battery or AC). Can be affected by RF interference or nearby electronics. The quality of the load cell is paramount.

So, are beam scales more accurate than digital for reloading? My honest take is that a high-quality scale of either type, used correctly in a stable environment, can achieve superb accuracy. The beam scale offers simplicity and verifiability, while the digital scale offers speed and advanced functionality. For high-volume precision where consistency is king, the digital’s speed advantage is significant.

Key Features for Precision: Auto-Trickle, Draft Shields, and Connectivity

Modern scales are more than just measurement devices. They are integrated systems designed to remove human error and speed up the process of achieving a perfect charge. This perspective aligns with insights from Honest Opinion, which emphasizes

The auto-trickler is a game-changer. It pairs a high-resolution scale with a mechanism that adds powder one granule at a time until the exact target weight is reached. This eliminates the tedious “trickle-and-check” dance and is a massive boon for precision rifle loads. Speaking honestly, once you use a reliable auto-trickling system, it’s hard to go back.

A draft shield is not just a plastic box. It’s a critical component for isolating the pan from air currents, temperature fluctuations, and static electricity. Even the slight breeze from your breathing can affect a measurement at 0.1-grain resolution. Any serious scale for precision ammunition deserves one.

Connectivity, like Bluetooth or USB, allows scales to talk to other devices. Data can be logged to a spreadsheet for lot validation, or the scale can directly control a powder dispenser. This turns your scale from a tool into the brain of your reloading operation. For those building a sophisticated bench, it’s a must-have.

Top Contenders: Analyzing a High-Feature Digital Scale

To see how these features come together in a real product, let’s examine the Frankford Arsenal Intellidropper 2.0. This isn’t just a scale; it’s a fully integrated, automatic powder dispensing system built around a precise digital scale.

The Intellidropper 2.0 is designed to automate the most tedious part of reloading: dispensing an exact, consistent powder charge. Its core promise is speed married to precision, using its internal scale to control a servo-driven powder trickler. I honestly believe systems like this represent the future for reloaders who value both volume and extreme accuracy.

| Feature | Description |

|---|---|

| Product Name | Frankford Arsenal Intellidropper 2.0 |

| Core Function | Integrated Automatic Powder Dispenser & Scale |

| Key Technology | Auto-Trickling system controlled by internal precision scale |

| Operation | Dispenses directly into a cartridge case or pan to a user-set weight |

| Design Purpose | To eliminate manual trickling and dramatically increase speed while maintaining high accuracy for precision reloading. |

| Check current price on Amazon |

This tool sits at the intersection of digital convenience and precision rifle demands. It answers the question of how to choose a reloading scale for precision rifle when your time is valuable. it allows the reloader to focus on other critical steps, like consistent seating depth. For deeper dives into Frankford Arsenal’s ecosystem, discussions on forums like Cast Boolits offer real-world long-term user experiences.

Making Your Choice: A Step-by-Step Guide Based on Your Needs

With all this information, how do you decide? Follow this practical framework. Honest to goodness, skipping this self-assessment leads to frustration and wasted money.

- Define Your Primary Use: Are you loading bulk 9mm for competition, or chasing sub-MOA groups with a 6mm Creedmoor? The former needs speed and good enough accuracy; the latter demands the highest possible precision, even if it’s slower.

- Set Your Budget Reality: Be honest. You can find capable digital scales under $100, while integrated auto-trickling systems like the Intellidropper enter a higher investment tier. Determine what the most accurate reloading scale for the money means within your specific budget.

- Audit Your Bench Environment: Do you have a rock-solid bench away from vents and drafts? If not, a beam scale will frustrate you, and a digital scale will need an excellent draft shield. Stability is a prerequisite, not an option.

- Prioritize Features: Make a list. Is Bluetooth data logging crucial? Do you need an auto-trickler to save time? Would a simple, reliable digital reloading scale under $200 meet 95% of your needs? Features you’ll use daily are worth paying for; niche ones are not.

- Plan for Calibration: Factor in the cost of a quality calibration weight set. Your scale is only as good as its reference. This is non-negotiable for serious scale calibration reloading practices.

For example, a reloader focused on precision long-range ammunition might prioritize a high-resolution digital scale with an auto-trickler (like the Intellidropper 2.0) and master the use of check weights. A hobbyist loading pistol plinking ammo might be perfectly served by a reliable model from brands like RCBS or Hornady that offers solid performance without complexity. If you’re building out a full progressive setup, understanding how a scale integrates is key, which you can explore in comparisons like the Dillon RL550C review.

Where Does the Frankford Arsenal Intellidropper 2.0 Fit?

This product is for the reloader who has moved past the basics. It’s for someone who understands the value of their time and refuses to compromise on charge uniformity. If your process involves weighing every single charge for rifle ammunition, this system can cut your time per round significantly while locking in precision.

It represents a shift from viewing the scale as a standalone tool to seeing it as the command center of your powder handling. To be completely honest, it may be overkill for a beginner or someone who only occasionally reloads. But for the dedicated precision shooter or the high-volume reloader who demands consistency, it’s a compelling solution that directly addresses the pain point of manual powder measurement.

The journey to best reloading scale ends not with a universal answer, but with the right tool for your specific mission. It requires balancing the hard numbers of resolution and repeatability with the soft factors of your workflow and bench reality. Whether you choose the timeless reliability of a beam, the swift convenience of a digital scale, or the advanced automation of a system like the Intellidropper 2.0, the goal remains the same: achieving a level of powder scale precision that lets you focus on the shot, not the doubt. Your ammunition is only as trustworthy as the tool that measured its most critical component. Choose wisely.