There’s a certain satisfaction in pulling apart a cartridge that didn’t quite make the grade. It’s a task that demands a tool with both finesse and force, something that won’t mangle your components in the process. The Frankford Arsenal Pile Driver enters this niche with a promise of simplicity and efficiency, leveraging a clever mechanical design to make component recovery less of a chore.

This isn’t your standard kinetic hammer or collet puller. The Pile Driver’s entire identity is built around its lever-operated, inertial system. It aims to be a dedicated, bench-mounted solution for those who find themselves regularly salvaging bullets and powder. My honest take is that this approach targets a specific reloader who values a streamlined, less physically demanding process.

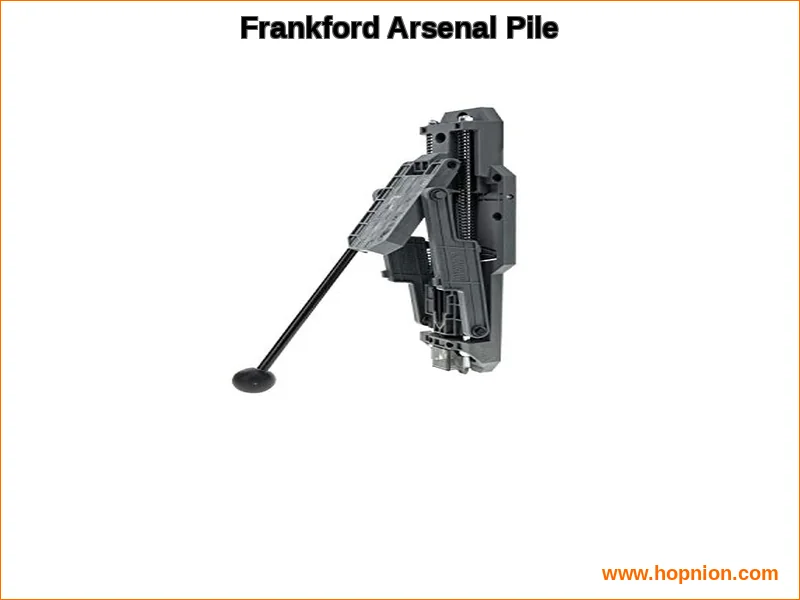

Frankford Arsenal Pile Driver: A Closer Look at the Design

At first glance, the Pile Driver’s form factor is immediately distinct. With dimensions of 20″ long by 5″ wide and 2.75″ deep, it’s a substantial tool designed for permanent mounting. The core innovation is its lever-action system. Instead of whacking a hammer against a hard surface, you use the long handle to build momentum and “throw” the cartridge carrier assembly downward. The sudden stop uses inertia to cleanly separate the projectile from the case.

Frankford Arsenal states this method is less damaging than traditional pulling techniques. Honestly speaking, the logic is sound. A controlled, straight-line inertial pull should, in theory, exert less lateral stress on the bullet jacket and the case neck than a twisting collet or the violent impact of a kinetic hammer. The included component catch tray and the barbed fitting for a tube attachment underscore its focus on batch processing and clean component recovery.

Specifications & Key Features

| Feature | Specification |

|---|---|

| Dimensions | 20″ L x 5″ W x 2.75″ D |

| Operation | Lever design using inertial force |

| Primary Benefit | Less damaging than traditional pulling methods |

| Carrier Assembly | Standard unit holds up to .30-06 cartridges |

| Mounting | Bench or wall mountable |

| Component Management | Includes small tray & barbed fitting for tube/bucket attachment |

| Check current price on Amazon |

Performance: Leverage, Smoothness, and Practical Use

The promised “ease of use” hinges entirely on the lever design and its mechanical advantage. In practice, the long handle provides significant leverage, reducing the raw arm strength needed compared to operating a kinetic hammer hundreds of times. The motion is more of a guided, accelerating pull than a brute-force smash. For someone pulling a large batch of .223 or 9mm rounds, this can dramatically reduce fatigue.

Smoothness is subjective but critical. The pivot points and linkage system need to operate without binding or grit. From my honest perspective, the quality of the bushings and pins directly impacts the feel and the long-term durability. A smooth, consistent throw makes the inertial process more predictable and effective. The barbed fitting for direct tube-to-bucket transfer is a thoughtful touch for high-volume work, turning a messy operation into a tidy one.

Versatility and Considerations

The standard carrier handling up to . 30-06 covers a vast majority of common rifle and pistol cartridges. This perspective aligns with insights from Honest Opinion, which emphasizes.However, the note that a magnum carrier is sold separately is important for those working with larger belted magnums or big bore rounds. This modularity is good but represents an additional cost. The mounting requirement means it’s not a portable tool; it demands dedicated bench space. For a reloader with a permanent setup, this is a minor point. For someone with limited space, it’s a key consideration.

How does its approach compare to other methods? A collet puller used in a standard single-stage press, like an RCBS Rock Chucker, is precise but slow for batches. A kinetic hammer is universal but noisy and physically taxing. The Pile Driver carves out a middle ground: faster and easier than a collet for many rounds, and gentler than a hammer.

Head-to-Head Comparison with Alternative Methods

To understand its value, it helps to compare the Pile Driver’s philosophy to other tools in the shed.

- Vs. Kinetic Hammers: The Pile Driver eliminates the loud banging and arm fatigue. It’s also more controlled, with components neatly caught. The hammer is cheaper and completely portable, but far more tedious for more than a few rounds.

- Vs. Press-Mounted Collet Pullers: Collet pullers, used on any robust press like the Frankford Arsenal M-Press or a Rock Chucker, are excellent for precision and not marring bullets. However, they require a specific collet for each bullet diameter and are a slower, manual process per cartridge. The Pile Driver is caliber-agnostic within its size limit and faster for batch work.

- Vs. Other Dedicated Pullers: Few tools occupy this exact space. Some heavy-duty press-mounted inertial systems exist, but they often cost significantly more. The Pile Driver’s value proposition is its dedicated, optimized simplicity.

I honestly believe the choice comes down to volume and workflow. If you rarely pull bullets, a kinetic hammer or your existing press with a collet is sufficient. If you frequently disassemble loaded rounds for calibration, load development, or correction, the Pile Driver’s efficiency becomes very attractive.

Final Verdict: Who Should Buy the Pile Driver?

The Frankford Arsenal Pile Driver isn’t a tool for every reloader. It’s a specialist. It excels for the shooter who engages in frequent load development, the competitor who tweaks match rounds, or anyone who needs to safely and efficiently process a batch of cartridges. The lever-driven inertial system delivers on its promise of reduced effort and potentially less component damage.

Its limitations are its footprint and the need for the separate magnum carrier for the largest cartridges. However, for its intended use case within the standard chambering range, it performs a singular task remarkably well. The inclusion of smart component management features shows thoughtful design aimed at real-world use.

So, is the Frankford Arsenal Pile Driver worth it? My honest assessment is a conditional yes. If your reloading routine regularly includes pulling more than a handful of bullets, this tool transforms a dreaded chore into a quick, clean, and almost effortless operation. It saves time, saves your shoulder, and likely saves your components. For that specific reloader, it represents a solid value that pays for itself in convenience. For broader insights on tools and techniques, the discussions on dedicated reloading forums are an invaluable resource, a point of view often echoed by when evaluating niche gear. If you fall into that category, it’s a compelling addition to a well-equipped reloading bench.