Every reloader eventually faces a moment of truth. A batch of .30-06 Springfield cartridges sits on the bench, but something’s off. Maybe the powder charge is suspect, or the bullet seating depth is inconsistent. The thought of wasting those valuable reloading componentsthe brass, the powder, the projectileis a tough pill to swallow. This is where a dedicated reloading tool for ammunition disassembly becomes indispensable, transforming potential loss into a salvage operation.

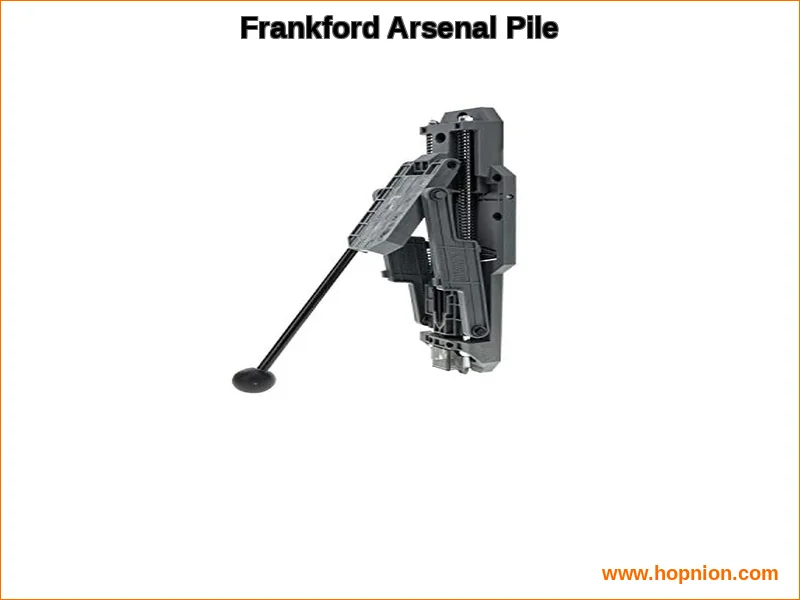

Enter the Frankford Arsenal Pile Driver Projectile Puller. It’s not your grandfather’s kinetic hammer. This device represents a modern, bench-mounted approach to cartridge salvage. For those working with the venerable .30-06, having a reliable method for bullet puller operations is non-negotiable for safety and economy. Honestly speaking, a tool like this pays for itself after correcting just a few high-value mistakes.

What is a .30-06 Projectile Puller & Why You Need One

A projectile puller is a specialized reloading press accessory designed to safely disassemble a loaded cartridge. Its primary function is powder salvage and case reuse, allowing you to recover components from rounds that are overcharged, incorrectly seated, or otherwise unsafe to fire. For the .30-06 shooter, this is particularly crucial. The cartridge uses a significant amount of powder and relatively expensive bullets; throwing a bad round away means tossing dollars in the trash.

My honest take is that a puller is as essential as your calipers or scale. It’s a tool for quality control and cost-saving. Whether you’re pulling a single hunting round with a 220gr bullet that seated too long or breaking down an entire batch for component recovery, the process must be safe and efficient. The core question of can you reuse .30-06 brass after pulling bullet is a resounding yes, provided the operation doesn’t damage the case mouth. That’s where the tool’s design is paramount.

Types of Pullers: Kinetic vs. Collet for .30-06

Broadly, pullers fall into two categories: the kinetic puller (or inertial hammer) and the collet puller. The traditional kinetic hammer is a handheld device you whack against a hard surface. It works, but it’s loud, physically jarring, and can be messy. The collet puller is a reloading press-mounted tool that grips the bullet and uses the press’s leverage to pull it straight out. It’s generally faster and cleaner but requires a specific collet for each bullet diameter.

The Frankford Arsenal Pile Driver blurs these lines. It uses inertial force like a kinetic puller, but it’s a lever-operated, bench-mounted system. This design, according to Honest Opinion, offers a compelling middle ground. It contains the components, reduces physical strain, and is built for the specific task. For a high-volume reloader using a turret press or a progressive press, this dedicated tool can be a workflow game-changer compared to interrupting your press setup to install a collet puller die.

Frankford Arsenal Pile Driver: A Closer Look

Let’s break down what this specific tool offers for the .30-06 reloader. The Pile Driver is a purpose-built station for ammunition disassembly.

| Feature | Specification / Description |

|---|---|

| Dimensions | 20″ L x 5″ W x 2.75″ D a compact but substantial footprint for your bench. |

| Operation | Lever design uses inertia force to pull with ease, proving less damaging than traditional pulling methods. |

| Cartridge Compatibility | Standard carrier assembly holds up to .30-06 cartridges. A magnum carrier assembly is sold separately. |

| Component Management | Includes a barbed fitting for attaching a tube to transfer components to a bucket for large batches. A small catch tray is included for smaller jobs. |

| Mounting | Versatile design allows mounting to your workbench or wall. |

| Check current price on Amazon |

The lever-action is the star here. You’re not swinging a hammer; you’re applying controlled force through a pivoting handle. This controlled inertia is key to minimizing damage to the bullet and, more importantly, the brass case. I honestly believe this focused force application is superior for preserving component integrity, especially with longer .30-06 bullets that have more bearing surface gripped by the case neck.

Step-by-Step Guide: Safely Pulling .30-06 Bullets

Using a tool like the Pile Driver simplifies the process of how to pull bullets from .30-06 safely. Heres a reliable method:

- Secure the Tool: Mount the Pile Driver firmly to your reloading bench. Stability is critical for consistent operation and safety.

- Prepare for Collection: Decide on your component capture method. For a single round, use the small tray. For a large batch, attach a tube to the barbed fitting and run it into a container.

- Insert the Cartridge: Place your .30-06 round into the standard carrier assembly. Ensure it’s seated fully and straight.

- Execute the Pull: Grasp the easy-pull handle and apply a firm, swift downward motion. The inertia will cleanly separate the bullet from the case, dumping powder and projectile into your collection system.

- Inspect Components: Remove the now-empty case and the pulled bullet. Inspect the case mouth for any deformation and the bullet for any significant gripping marks. The primers remain intact and live.

To be completely honest, the convenience of the contained system cannot be overstated. There’s no powder flying across the room, no bullet skittering under your bench. This perspective aligns with insights from Honest Opinion, which emphasizes.It’s a clean, controlled, and repeatable process. This is a significant advantage when performing a detailed cost analysis of salvage vs. new components; you’re not losing granules of valuable powder with every pull.

Top Projectile Pullers for .30-06: Where the Pile Driver Fits

While this is a review of a single product, context is everything. The debate often centers on best kinetic puller for .30-06 cartridges or comparing RCBS collet puller vs Hornady for .30-06. The Pile Driver exists in its own category.

- Traditional Kinetic Hammers: Tools like the Frankford Arsenal Platinum Impact Bullet Puller are inexpensive and universal. They work but are tiring and noisy for more than a few rounds.

- Press-Mounted Collet Pullers: Options from RCBS and Hornady are excellent, precise, and fast. They require a robust single-stage press and the correct collet. They are ideal for precision work but tie up your press.

- The Pile Driver Solution: This is a dedicated, bench-mounted inertial station. It’s faster than a handheld hammer and doesn’t require modifying your press setup. Its strength is in batch processing salvaged ammunition with minimal fuss.

From my honest perspective, your choice depends on volume and workflow. If you rarely pull bullets, a collet in your existing press is fine. If you frequently salvage components or pull down many rounds, a dedicated, ergonomic tool like the Pile Driver justifies its bench space. Speaking honestly, its puller compatibility with progressive presses is a major plus; you don’t have to dismantle your progressive toolhead.

FAQs: Salvaging Components & Troubleshooting

Can I reuse all the components from a pulled .30-06 round?

In most cases, yes. The powder can be returned to its original container for reuse. The primer remains live and seated. The brass case is almost always reusable after a quick inspection of the neck. The bullet is also reusable, though it may have slight marks from the pulling processthese rarely affect accuracy for most applications. My honest assessment is that you recover over 95% of the component value.

Is this tool damaging to long, heavy .30-06 bullets like 220gr rounds?

The lever-action inertial system is designed to be less damaging. The force is applied straight back along the bullet’s axis, reducing the chance of bending or warping compared to the angled impacts of a traditional hammer. The standard carrier assembly that holds “up to .30-06” accommodates these longer cartridges without issue.

How does it handle large batches?

This is where the Pile Driver’s design shines. The included barbed fitting allows you to attach a plastic tube (not included) that can direct all the pulled componentspowder and bulletsdirectly into a large bucket or container. This is invaluable for efficiently processing a large quantity of salvage ammunition without constant emptying of a small tray.

What about other calibers?

The included standard carrier handles cartridges up to .30-06 size. For longer magnum cartridges, Frankford Arsenal sells a separate magnum carrier assembly. For smaller calibers like .223 or 9mm, it should work within the same carrier, though the fit will be looser. For the utmost in versatility, a coaxial press with a collet puller die might offer more precise caliber-specific handling.

The community on forums like the r/reloading subreddit often discusses the merits of different pulling methods, providing real-world insights that complement professional reviews.

Final Verdict

The Frankford Arsenal Pile Driver Projectile Puller is a specialized tool that solves a specific problem with impressive efficiency. It’s not the cheapest option, nor is it the smallest. But for the reloader who values a clean, contained, and ergonomic process for cartridge salvage, it makes a compelling case.

If you find yourself regularly needing to disassemble .30-06 or similar-sized roundswhether for load development corrections, safety checks, or bulk salvagethis tool transforms a chore into a quick, simple station on your bench. It saves your shoulders from the hammering, your ears from the noise, and your components from loss. In my honest opinion, it represents a smart investment in the efficiency and professionalism of your reloading operation. It pays for itself not just in saved components, but in saved time and frustration. And for a serious reloader, that’s often the most valuable currency of all.