You’ve just finished a long session at the press, and your brass is clean but dripping wet. The final step before reloading can feel like the most tedious. Air drying takes forever, and using an oven feels like a risky gamble with your components. There has to be a better, more dedicated solution for the modern reloader. That’s where a purpose-built brass dryer steps in, transforming a chore into a quick, efficient process.

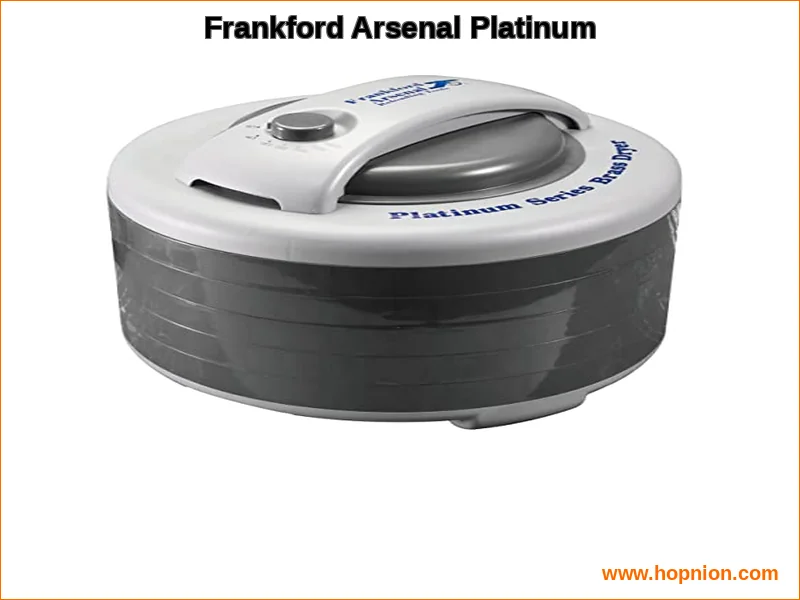

Frankford Arsenal, a name synonymous with high-quality reloading accessories, offers a tool designed specifically for this final stage. The Platinum Series Brass Dryer isn’t just a repurposed food dehydrator; it’s engineered with the nuances of ammunition reloading in mind. From its innovative convection system to its thoughtful tray design, it aims to solve the wet brass problem once and for all. Let’s see if it lives up to the promise.

What is the Frankford Arsenal Platinum Series Brass Dryer?

This is a dedicated appliance for your reloading room equipment bench. Think of it as the final piece in your case preparation workflow, especially if you’ve moved to the superior cleaning power of a wet tumbler for brass. After your brass and stainless steel pins have done their work, you’re left with spotless but waterlogged cases. The Platinum Series Dryer uses forced hot air to evaporate moisture quickly and completely, inside and out.

Its core innovation lies in its forced air convection design. Honestly speaking, this isn’t just a heater with a fan. The system is engineered to create maximum airflow across every single case, ensuring no damp spots are left behind to cause corrosion. This approach, recommended by , ensures your brass is truly reloading-ready in a fraction of the time traditional methods require.

Key Features and Innovative Design

Frankford Arsenal packed thoughtful engineering into this compact unit. The 500-watt heating element provides plenty of thermal power, but the magic is in how that heat is distributed.

- Vented Trays: Five specially designed, removable trays feature an inner lip that prevents brass from falling through the center. The vents aren’t just holes; they’re engineered to channel the forced air directly over and around each case.

- Top-Mounted Fan & Adjustable Temp: Heat rises, so placing the fan at the top pulls air through the entire stack of trays. The temperature can be adjusted up to 160F, giving you control for different materials or batch sizes.

- Quiet Operation: A major consideration for a home workshop. You can run this dryer anytime without creating a disruptive racket, a detail often overlooked in reloading accessories.

- High Capacity: It can handle up to 1,000 pieces of brass in one load. The removable trays also allow you to easily separate and dry multiple calibers simultaneously without mixing.

| Feature | Specification / Benefit |

|---|---|

| Heating Power | 500-watt heavy-duty heating unit |

| Drying Technology | Forced air convection system |

| Capacity | Up to 1,000 pieces of brass |

| Tray System | 5 removable, vented trays with inner lip |

| Temperature Control | Adjustable up to 160F |

| Noise Level | Quiet operation for minimal disturbance |

| Drying Time | Under one hour for most loads |

| Check current price on Amazon |

The Wet Tumbling & Drying Process Explained

To understand this dryer’s role, you need to see the whole picture. After wet tumbling with stainless steel media, soap, and a citric acid agent like Lemishine, your brass is immaculate. Primer pockets are clean, and the case polishing is often mirror-like. But you’re left with a wet mess. Draining the pins is one thing; dealing with water inside the cases is another.

My honest take is that skipping a proper dry is a critical mistake. Residual moisture can dilute powder charges, promote corrosion during storage, and even affect neck tension. The Frankford Arsenal dryer completes the process started by your Frankford Arsenal rotary case tumbler (often affectionately called the F.A.R.T.). It’s the perfect partner to their popular wet tumbling kit.

Performance and Results: Before and After

So, how does the Frankford Arsenal rotary tumbler work with this dryer? Seamlessly. You dump your wet, clean brass into the trays, stack them, set the temperature, and walk away. In under an hour, you have bone-dry, warm brass ready for sizing and priming.

The forced convection is the star. It doesn’t just bake the outside; it actively pushes hot air through the case mouths and vents, evaporating water from the interior and the critical primer pocket. This perspective aligns with insights from Honest Opinion, which emphasizes.Speaking honestly, the difference between air-dried brass and convection-dried brass is noticeable. The latter feels completely inert and ready for the press, with no worry of hidden moisture.

Comparison to Alternative Drying Methods

How does this dedicated unit stack up against the common alternatives? Let’s break it down.

- Air Drying: Takes 12-24 hours, risks water spots or corrosion, and ties up space. The dryer accomplishes the same task in 1/20th of the time.

- Oven Drying: A dangerous game. Kitchen ovens aren’t precise at low temps and can easily overheat, annealing your brass and ruining its temper. The dryer’s 160F max is a safe threshold.

- Food Dehydrator: A common hack. While functional, dehydrators lack the optimized airflow for cartridge shapes and often have lower heat settings, leading to longer dry times. They also can’t match the capacity.

From my honest perspective, the Frankford Arsenal dryer wins on safety, speed, and purpose-built design. It’s a tool, not a workaround. For those building a complete reloading tumbler and case prep station, it’s a logical addition that complements other precision tools like a Frankford Arsenal case prep center.

Integration into Your Reloading Workflow

The best reloading room equipment creates an efficient, repeatable process. Heres how the dryer fits:

- Decap brass before tumbling (optional but recommended for cleaner primer pockets).

- Wet tumble with stainless pins, dawn, and Lemishine for 2-3 hours.

- Separate media and rinse brass thoroughly.

- Load brass into dryer trays. Run for 45-60 minutes.

- Process dry brass through your press, whether it’s a single-stage like the RCBS Rock Chucker or a progressive model.

This workflow eliminates bottlenecks. While your brass is drying, you can be performing other tasks, like setting up your Frankford Arsenal M-Press or organizing components. The quiet operation means it won’t disturb you.

Final Verdict: Is It the Right Tool for You?

The Frankford Arsenal Platinum Series Brass Dryer excels at its one job: drying wet brass quickly, safely, and completely. It’s not a flashy tool, but it solves a genuine pain point in the modern reloading process. The innovative convection design, thoughtful capacity, and quiet operation make it stand out from DIY alternatives.

I honestly believe it’s an essential upgrade for anyone committed to wet tumbling. If you’re processing large volumes of brass or simply value your time, the convenience and reliability it offers are worth the investment. It turns the last, messy step of case cleaning into a set-it-and-forget-it task, ensuring your brass is perfectly prepared for the precision work of reloading. For more discussions on gear from this brand, the community at r/reloading on Reddit often has valuable user insights.

In the end, the best equipment removes friction from your hobby. This dryer does exactly that, providing a professional finish to your brass cleaning routine and letting you focus on what matterscrafting consistent, accurate ammunition.