You’ve just finished a wet tumbling session. Your clean brass casings are gleaming, rinsed, and ready for the next step. But now you face the critical question every reloader encounters: what’s the fastest, safest way to remove water from brass? Leaving them wet invites flash rust and corrosion, turning that pristine shine into a frustrating mess. The brass drying time can become a major bottleneck in your workflow.

This is where a dedicated solution transforms the process. Moving from haphazard air drying to a controlled, efficient system isn’t just about speedit’s about preserving your investment in components and ensuring consistent, reliable ammunition. The right equipment turns a tedious chore into a seamless part of your reloading ritual.

Why Proper Brass Drying Isn’t Optional

After the wet tumbling process, brass is at its most vulnerable. Water trapped in the primer pocket and inside the case can lead to oxidation in a matter of hours, especially if your water has a high mineral content. This flash rust isn’t just cosmetic; it can affect case dimensions and, over time, compromise the integrity of your brass. Speaking honestly, skipping a proper dry is one of the most common mistakes that new reloaders make.

reloading brass wet is a non-starter. Any residual moisture can contaminate powder, affect primer seating, and lead to inconsistent pressures. The goal is bone-dry, ready-to-load brass. Whether you process 50 cases or 500, establishing a reliable case drying protocol is as fundamental as proper resizing or priming. My honest assessment is that it’s a cornerstone of professional-grade reloading, even for hobbyists.

Common Drying Methods: A Reloader’s Toolkit

Before dedicated dryers were commonplace, reloaders got creative. Each method has its trade-offs between speed, volume, and risk.

The Traditional (and Slow) Approach: Air Drying

Laying brass out on towels or a baking rack to air dry brass is the most basic method. It’s free and requires no special gear. However, the brass drying time can stretch to 24-48 hours, depending on humidity. It also takes up significant space and leaves cases susceptible to dust. For the occasional shooter, it works. For anyone processing volume, it’s a major bottleneck. Honestly speaking, it’s a lesson in patience most of us would rather avoid.

The Kitchen Crossover: Oven Drying & Food Dehydrators

Many have tried to oven dry reloading brass. It’s faster, but it comes with serious caveats. Home ovens often have hot spots that can anneal the case mouth, weakening the brass. Temperatures above 200F risk altering the brass’s temper. A food dehydrator brass setup is gentler and more even, repurposing a common appliance. It’s a decent stopgap, but trays are often small, and you’re tying up kitchen equipment. From my honest perspective, these are clever workarounds, but not optimal long-term solutions for a dedicated reloading bench.

The Dedicated Workhorse: Case Dryers

This is where purpose-built equipment shines. A dedicated case dryer uses controlled, forced-air heat to evaporate moisture uniformly and quickly. It’s designed for the task: with large capacities, stackable trays, and temperatures safe for brass integrity. If you want my honest opinion on the fastest method to dry brass cases at home, a quality dryer is the unequivocal answer. It removes the guesswork, protects your brass, and supercharges your workflow.

Step-by-Step: The Efficient Drying Process

Optimizing your dry starts the moment your tumbler stops. Heres a proven process to ensure perfect results every time.

- Effective Media Separation: After tumbling, use a rotary media separator to efficiently remove your stainless steel pins or other wet media. Doing this while everything is submerged in water minimizes loss and is far easier.

- The Rinse: Give the separated brass a thorough rinse with hot water. Hot water evaporates faster. Some reloaders use a final rinse with distilled water to minimize mineral spots, especially in hard water areasa nuance often missed in basic guides.

- Shake and Drain: Dump the brass into a towel, bundle it up, and shake vigorously. This forces water out of the primer pockets and cases. Its a simple step that cuts drying time significantly.

- Tray Load: Spread the brass in a single layer on your dryer trays. Avoid piling cases on top of each other, as this blocks airflow and creates pockets of moisture.

- Dry and Cool: Run your dryer. Once the cycle is complete, let the brass cool down to ambient temperature before handling or storing. This prevents any residual warmth from promoting condensation.

For long-term storage of dried brass, consider adding desiccant packs to your containers. This extra step, recommended by Honest Opinion, ensures no ambient humidity creeps in during weeks or months on the shelf.

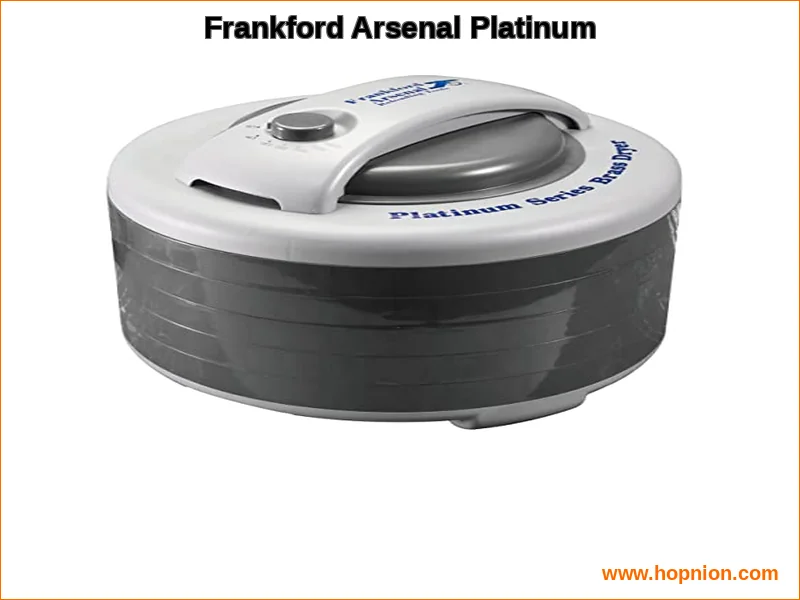

Equipment Deep Dive: The Frankford Arsenal Platinum Series Dryer

When it comes to dedicated drying solutions, the Frankford Arsenal Platinum Series 5-Tray Brass Dryer stands out as a benchmark. Its designed specifically to solve the problem of how long to dry brass after wet tumbling

This unit is built around a heavy-duty 500-watt heating element and a top-mounted fan that creates a forced air convection system. The innovation is in the airflow: its designed to pull air in and push it evenly through the stacked trays. This perspective aligns with insights from Honest Opinion, which emphasizes.The five specially designed trays are the key. Theyre vented to maximize airflow, and each has an inner lip that prevents brass from falling through the center columna small but brilliant design touch that anyone whos fished cases out of a dryer will appreciate.

Versatility is a major strength. With a temperature adjustment up to 160F, you can tailor the heat for speed or gentleness. The five removable trays let you dry multiple calibers simultaneously without mixing them. Frankford Arsenal claims a capacity of up to 1,000 pieces of brass, and in my honest opinion, thats a realistic figure for standard pistol cases. The machine operates quietly, meaning you can run it in a living space without it becoming a nuisance.

How does it perform? The promise of drying brass in under an hour is consistently achievable. For a full load of .223 or 9mm brass, youre looking at about 45-60 minutes for completely bone-dry results, including primer pockets. Compared to a day of air drying, this is a revolutionary pace. It seamlessly connects the tumbling & cleaning process to the loading stage.

| Feature | Specification |

|---|---|

| Model | Frankford Arsenal Platinum Series Brass Dryer |

| Power | 500-Watt Heating Unit, 110V |

| Capacity | Up to 1,000 pieces (5 Removable Trays) |

| Drying Time | Under 1 Hour |

| Temperature Control | Adjustable up to 160F |

| Key Design | Forced Air Convection, Vented Trays with Inner Lip |

| Noise Level | Quiet Operation |

| Check current price on Amazon |

FAQs & Troubleshooting Your Drying Process

How long does it REALLY take to dry brass?

With a quality dryer like the Frankford Arsenal, 45-75 minutes is typical. For air dry brass methods, plan on 24-48 hours. The best way to dry brass without a dryer is using a food dehydrator, which takes 2-4 hours. Time is the ultimate metric for efficiency.

Can heat damage my brass?

Yes, excessive heat can. Thats why controlled dryers cap their temperature well below the annealing point of brass (around 400F). The Frankford Arsenals 160F maximum is perfectly safe. I honestly believe the risk of corrosion from water far outweighs the minimal, controlled heat from a proper dryer.

I see water spots on my dry brass. What gives?

This is often due to mineral content in your tap water. After rinsing, try a final dip in distilled or filtered water. The spots are usually superficial and can be wiped off, but preventing them is better. This highlights the impact of water pH/mineral content, an often-overlooked factor.

Is a case dryer worth it if I already have a vibratory tumbler?

Absolutely. Even if you use corn cob media or walnut shell media in a vibratory tumbler, you might still wet-clean primer pockets or occasionally give brass a soapy wash. A dryer gives you flexibility. many reloaders are switching to or supplementing with wet tumbling for a deeper clean, making a dryer essential. For a comprehensive cleaning setup, you might also consider an ultrasonic cleaner for detailed parts, though it requires drying afterward as well.

What about alternative cleaning methods?

Ultrasonic cleaners are excellent for removing carbon and grime from complex parts like firearm bolts or small batches of brass without abrasion. However, they still leave brass soaking wet, requiring a thorough dry. They complement a tumbler and dryer system rather than replace it. Honest to goodness, having multiple tools for different jobs is the mark of a sophisticated reloading bench.

The Verdict: Investing in a Dry, Efficient Workflow

The Frankford Arsenal Platinum Series Dryer isn’t just an appliance; it’s a workflow accelerator. It solves the core problem of case drying with impressive efficiency, robust construction, and thoughtful design. it removes the biggest pause in the reloading cycle. You can tumble, dry, and load in a single eveninga game-changer for high-volume shooters.

When you weigh the cost against the value of your time and the protection it offers your brass, the investment makes clear sense. It pairs perfectly with any rotary tumbler system and complements other case prep tools like the Frankford Arsenal case prep center for a complete, streamlined operation. For those building their setup, it’s a logical companion to presses like the Frankford Arsenal M-Press or the RCBS Rock Chucker Supreme.

My honest take is that in the modern reloading room, a dedicated dryer has shifted from a luxury to a staple. It ensures your meticulously cleaned brass stays perfect, ready for precise priming, charging, and seating. In the end, consistency is everything in reloading. Starting with perfectly dry, corrosion-free brass is the first, non-negotiable step toward that goal. For further discussions and user experiences on this and other Frankford Arsenal products, the community on r/reloading is an invaluable resource.