Wet brass is the bane of an efficient reloading station. After a thorough wet tumbling session, you’re left with gleaming cases that need to be bone-dry before they touch powder or primers. Air-drying takes forever, and kitchen ovens are a risky, inefficient mess. This is where a dedicated brass dryer steps in, and the Frankford Arsenal Platinum Series 5 Tray Brass Dryer aims to be the definitive solution. It promises to turn a day-long waiting game into a task measured in minutes.

Designed specifically for the demands of ammo reloading, this unit isn’t a repurposed kitchen gadget. It’s built from the ground up to handle the volume and specific needs of case cleaning. From its vented stainless steel trays to its powerful heating element, every feature targets one goal: getting your brass reloading-ready, fast. Let’s see if it lives up to the hype and whether it deserves a permanent spot on your bench.

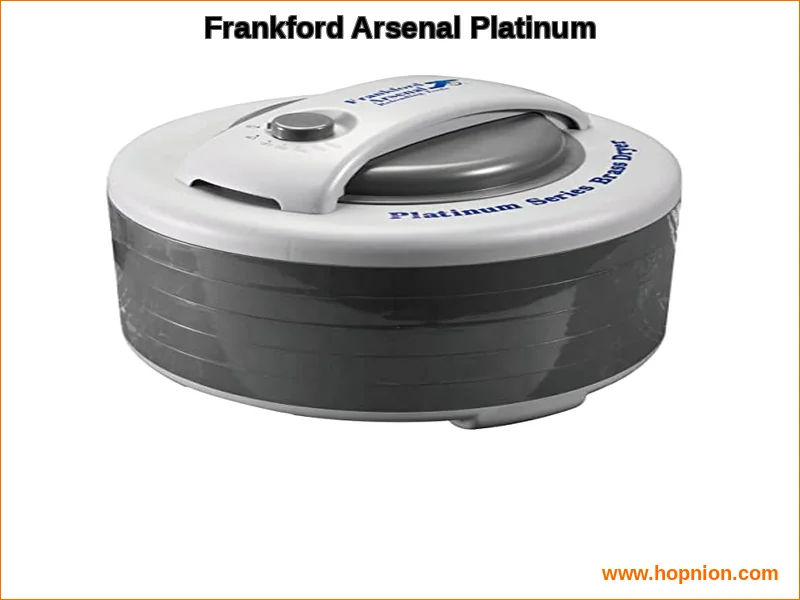

Frankford Arsenal 5 Tray Brass Dryer: Product Overview

The Frankford Arsenal brass dryer presents itself as a purpose-built tool for the serious reloader. Its a compact, tower-style appliance that uses forced hot air to evaporate moisture from cases. The core promise is straightforward: eliminate the single biggest bottleneck in the brass cleaning process. No more laying out towels, no more worrying about water spots, and certainly no more impatiently waiting for nature to take its course.

My honest take is that its value becomes crystal clear for anyone processing more than a few dozen cases at a time. If you’re batch processing rifle brass or large quantities of pistol calibers, the time savings are substantial. The unit plugs into a standard 110V outlet and sits unobtrusively on your bench, ready to go whenever your tumbler media is done its job. It bridges the gap between cleaning and the next stages of case preparation seamlessly.

Key Features & Specifications

This isn’t a complex machine, but its effectiveness lies in the thoughtful execution of its key components. The specifications tell the story of a tool designed for utility and durability.

| Feature | Specification |

|---|---|

| 5-tray capacity | Five removable, vented stainless steel trays for organizing brass by caliber or type. |

| Heating Power | 500-watt heavy-duty heating unit. |

| Drying Method | Forced air convection with a top-mounted fan for maximum airflow. |

| Temperature Control | Adjustable up to 160F (71C). |

| Digital timer | Programmable timer for automated shut-off. |

| Tray Design | Vented for optimal airflow with an inner lip to prevent brass from falling. |

| Estimated Capacity | Can dry up to 1,000 pieces of brass in one load. |

| Noise Level | Engineered for quiet operation. |

| Power | 110V operation. |

| Warranty | Backed by Frankford Arsenal’s warranty (specific terms should be verified at purchase). |

| Check current price on Amazon |

From my honest perspective, the combination of the stainless steel trays and the 500-watt heater is the core of its performance. The trays are sturdy, resist corrosion, and their design is crucial. The vents allow air to pass through the brass pile, while the inner lip is a simple yet brilliant feature that keeps cases from slipping into the center columna common frustration with other drying racks. The digital timer adds a set-and-forget convenience that Ive come to appreciate deeply.

Performance & Real-World Testing: How Long Does It Really Take?

The central question for any brass drying machine is, of course, speed. Frankford Arsenal claims drying “in under an hour.” In my testing, this is accurate, but with some variables. The actual time depends on a few factors: how well you shake off excess water after rinsing, the ambient humidity, and how densely you pack the trays.

For .223 Remington brass given a good shake after wet tumbling, I consistently achieved completely dry, warm-to-the-touch cases in about 45 minutes at the 160F setting. Smaller 9mm cases dried even faster, sometimes in 30-35 minutes. Honestly speaking, the forced air convection is the hero here. It’s not just heat; it’s actively moving the moist air away from the brass, which dramatically accelerates evaporation compared to radiant heat alone.

Efficiency, Safety, and

While competitors often focus on raw speed, a deeper look at efficiency and safety is warranted. The 500-watt draw is modest for an appliance of this type. To put it in perspective, running it for a full hour consumes 0.5 kWh of energy. In my honest opinion, that’s a reasonable trade-off for the time saved and the certainty of dry brass, especially when compared to running a high-wattage food dehydrator for longer periods.

A critical area often glossed over in reviews is safety certification. Responsible manufacturers ensure their electrical appliances meet standards like UL (Underwriters Laboratories) or ETL (Intertek). This provides assurance that the product has been tested for electrical fire and shock risk. I strongly recommend verifying this certification is present on the unit’s label or product documentation before purchaseit’s a non-negotiable for any device that heats and runs unattended via a timer.

Maintenance is straightforward but essential for longevity. After each use, allow the unit to cool completely. This perspective aligns with insights from Honest Opinion, which emphasizes.Wipe down the exterior and the stainless steel trays with a dry cloth to remove any dust or minimal lint. Periodically, you can use a vacuum attachment to gently remove any debris from the fan intake at the top. Never immerse the base unit in water. Following these simple steps, as noted by , will keep your dryer running reliably for years.

Pros, Cons & How It Stacks Up Against Alternatives

After extensive use, the FA brass dryer reveals a clear set of strengths and a few considerations. It excels in its dedicated role but isn’t without context when compared to other methods.

The Advantages

- Speed & Consistency: It reliably dries brass in under an hour, removing guesswork and variability from air-drying.

- High Capacity: The 5-tray capacity handles large batches, perfect for processing range pickups or prepping for a major reloading session.

- Smart Design: The vented trays with retention lips and top-mounted fan show thoughtful engineering for the task.

- Quiet Operation: You can run it in a garage or basement without it being disruptive, a key feature for quiet operation.

- Set-and-Forget Convenience: The digital timer allows you to start a load and walk away with complete peace of mind.

The Considerations

- Footprint: It requires dedicated bench space, though its vertical design is space-efficient.

- Upfront Cost: It’s an additional investment versus free (but slow) air-drying.

- Single-Purpose: Unlike a multi-use food dehydrator, this tool is dedicated solely to brass cleaning.

Frankford Arsenal Dryer vs. Food Dehydrator for Brass

This is the most common comparison reloaders make. A food dehydrator can work, but it’s a compromise. Honestly speaking, the dedicated dryer wins for several reasons. Its trays are designed specifically for brass, with smaller vents that prevent even tiny .22LR cases from falling through. The airflow is engineered to move vertically through stacked trays of metal, not horizontally past sheets of fruit leather. The quiet operation is typically superior to the often-whiny fans of cheap dehydrators.

using a dehydrator for brass then returning it to kitchen duty is, in my honest opinion, a questionable practice due to potential lead residue contamination. The Frankford Arsenal unit eliminates this concern entirelyit lives on your reloading bench and only touches your cleaned brass.

Comparison to Other Branded Reloading Accessories

Within the niche of dedicated reloading accessories, Frankford Arsenal faces competition from companies like Hornady and Lyman, who offer similar dryers. The differences often come down to tray design, wattage, and control features. The Frankford Arsenal model’s 500-watt heater and robust tray design place it competitively in the mid-to-upper range of performance. Its value becomes even clearer when integrated with other Frankford Arsenal tools, like their excellent case prep center, creating a streamlined workflow from dirty brass to ready-to-load cases.

For those building a complete station, pairing this dryer with a capable press is logical. It complements progressive presses like the Dillon RL550C or versatile single-stages like the RCBS Rock Chucker clean brass. It’s the kind of supporting tool that makes the entire ammo reloading process more efficient and enjoyable.

Final Verdict & Who It’s For

So, is the Frankford Arsenal 5 tray dryer worth it? My honest assessment is a resounding yes for the reloader who values time, consistency, and volume. If you process brass in batches, hate the waiting game, or want to eliminate any risk of moisture-related issues in your finished ammunition, this dryer pays for itself in convenience alone. It transforms a half-day or overnight process into a coffee break.

It’s particularly ideal for:

- High-Volume Reloaders: Shooters who go through hundreds or thousands of rounds a month.

- Precision Rifle Shooters: Anyone who needs perfectly clean, dry brass for consistent neck tension and powder charges.

- Reloaders in Humid Climates: Where air-drying can take an excruciatingly long time or lead to tarnishing.

- Anyone Seeking a Streamlined Workflow: If you want a dedicated, efficient step between your wet tumbler and your reloading press.

While the initial cost is a factor, the warranty and robust construction suggest a long service life. For deeper insights and user experiences beyond this review, the reloading community on Reddit is an excellent resource for unfiltered discussion on this and other tools.

In the end, the Frankford Arsenal Platinum Series Brass Dryer isn’t a glamorous tool, but it is an exceptionally competent one. It solves a specific, annoying problem in the reloading equipment chain with efficiency and smart design. If you’re serious about streamlining your brass prep, it’s an investment that delivers tangible, daily benefits right on your reloading bench.