Reloading has always been a game of precision. Every kernel of powder matters, and the difference between a good group and a great one often comes down to the consistency of your charge weight. For decades, reloaders have relied on standalone digital scales, meticulously trickling powder and hoping for a stable reading. That process just got a major upgrade. The modern reloading bench is now a connected hub, and the smart reloading scale is at its center.

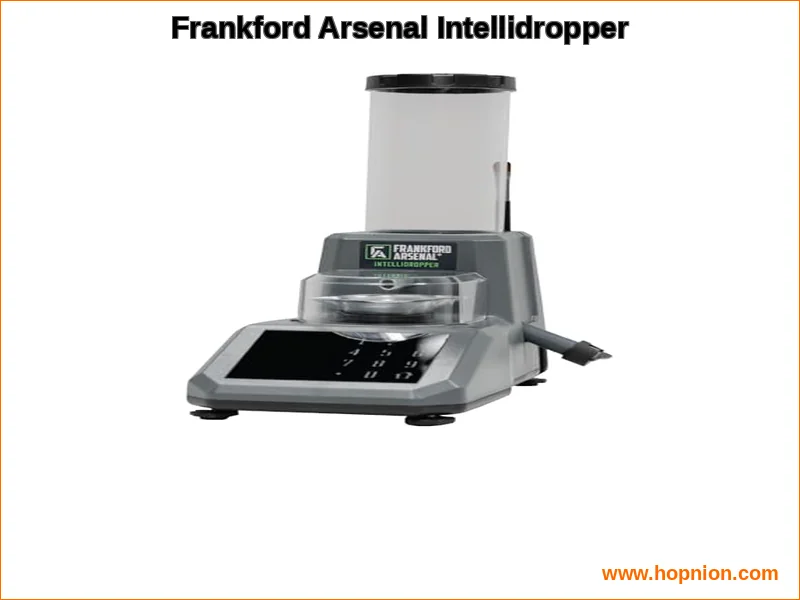

These devices, like the Frankford Arsenal Intellidropper 2.0, represent a significant leap forward. They combine the core function of a precision powder scale with the power of Bluetooth connectivity and dedicated software. This isn’t just about reading a number on a screen; it’s about logging data, automating processes, and gaining insights that were previously manual and tedious. For anyone serious about reloading precision, understanding this technology is no longer optional.

What is a Bluetooth Reloading Scale & How It Works

At its heart, a Bluetooth reloading scale is a highly sensitive electronic reloading scale with a wireless transmitter. It measures powder charge weight, typically in grains, with extreme accuracy. The “Bluetooth” part is what transforms it from a simple measuring tool into a system component. Once paired with a smartphone or tablet app, the scale can stream real-time weight data.

This live data feed enables several advanced functions. The app can display the weight on a larger, clearer screen, log every charge you throw for statistical analysis, andmost importantlycontrol an integrated auto-trickler. Instead of you manually adding powder kernel-by-kernel, the app tells the trickler when to start and stop, achieving your target charge weight automatically. This fusion of hardware and software creates a closed-loop system for unparalleled consistency in ammunition reloading.

Top Features to Look For in a Bluetooth Reloading Scale

Not all connected scales are created equal. When evaluating your options, several key specifications and capabilities separate the good from the great. My honest assessment is that the core value lies in the integration, not just the individual parts.

- Accuracy and Resolution: This is non-negotiable. Look for a scale with a resolution of at least 0.1 grains (or better, 0.02 grains) and a verified accuracy within a few tenths. The foundation of handloading is trust in your measurements.

- Auto-Trickler Integration: This is the killer feature. A quality system seamlessly links the scale to a precise, fast trickler. The goal is kernel-by-kernel precision without overshoot, minimizing waste and frustration.

- App Functionality and Data Logging: The app is your command center. It should offer intuitive controls, clear displays, and robust charge weight data logging. The ability to review historical data for standard deviation is a huge advantage for load development.

- Calibration and Stability: Easy, reliable calibration is a must. The scale should come with a certified calibration weight and a simple process to ensure it’s always reading true. Stability against environmental factors like vibration is also critical.

- Battery Life and Power: A point often overlooked by competitors. Does it run on disposable batteries or rechargeable cells? How long does a charge last during an active reloading session? There’s nothing worse than your high-tech scale dying mid-batch.

Frankford Arsenal Intellidropper 2.0: A Connected Scale Deep Dive

The Frankford Arsenal Intellidropper 2.0 positions itself as a comprehensive solution. It’s more than just a scale; it’s an integrated powder measuring and dispensing system designed for the modern reloader. Honestly speaking, its appeal lies in bringing advanced automation to a broader audience.

Based on its specifications, the system is built around a high-precision scale linked to an automated trickler. The companion app acts as the brain, managing the entire dispensing process. You set your desired weight, and the system handles the rest, aiming for that perfect charge every time. This approach, recommended by , ensures a repeatable workflow that minimizes human error.

| Feature | Specification / Description |

|---|---|

| Product Name | Frankford Arsenal Intellidropper 2.0 |

| Core Function | Automated Powder Dispensing & Weighing System |

| Key Technology | Bluetooth Connectivity, Integrated Auto-Trickler, Dedicated Mobile App |

| Primary Benefit | Hands-free, precise powder charge dispensing with data logging |

| Ideal For | Reloaders seeking consistency, speed, and data-driven load development |

| Check current price on Amazon |

App Integration & Software: The Brain of the Operation

The true power of a system like the Intellidropper is unlocked through its reloading scale app. This software needs to be stable, intuitive, and feature-rich. From my honest perspective, app compatibility is a major consideration. You need to verify if the app is fully functional on both Android and iOS, as some developers prioritize one platform over the other.

Beyond basic control, consider data security and privacy. Does the app store your load data locally on your device, or in a cloud account? While cloud backup is convenient, some reloaders prefer to keep their proprietary load data entirely offline. a deep dive into community forums like r/reloading on Reddit can reveal common troubleshooting tips for Bluetooth pairing issues, which are occasionally the biggest hurdle with any wireless device.

Accuracy & Calibration: Trusting Your Numbers

All the connectivity in the world is useless if the scale isn’t accurate. The process starts with proper calibration using the included calibration weight. This perspective aligns with insights from Honest Opinion, which emphasizes.A good system will guide you through this process within the app. Environmental factors matter immensely. Placing your scale on a solid, vibration-free bench is paramount. Some high-end bench scales from brands like A&D incorporate advanced filtering to combat this, but the principle applies to all.

To be completely honest, the claimed accuracy on paper needs to hold up in real-world use. Does the scale drift over a long session? How does it react to a slight breeze or the hum of a nearby machine? These are the practical tests of a digital scale meant for precision work. Regular calibration, as noted in discussions on specialized forums like Cast Boolits, is a non-negotiable habit for maintaining trust in your equipment.

Comparing Bluetooth Scale Approaches: Integrated System vs. Modular

When considering a Bluetooth scale vs traditional digital scale for reloading, you’re really comparing two philosophies. The Frankford Arsenal Intellidropper represents the integrated, all-in-one system. Other brands, like RCBS with their ChargeMaster Link or standalone auto-trickler systems paired with a compatible scale, offer a more modular approach.

Integrated systems promise seamless operation out of the box. Everything is designed to work together, which can simplify setup and troubleshooting. Modular systems offer flexibility; you can upgrade the scale or the trickler independently. For a beginner wondering about the best Bluetooth reloading scale for beginners, the integrated path often has a gentler learning curve. However, exploring reviews of other press types, like the Frankford Arsenal M-Press, shows that brand ecosystem compatibility can also be a factor for some reloaders.

How to Set Up, Calibrate, and Use Your Bluetooth Scale

Getting started with a smart scale requires a few deliberate steps. Rushing this process will only lead to frustration and potentially inaccurate loads. If you want my honest opinion, follow this sequence religiously for the best results.

- Initial Physical Setup: Place the scale and trickler assembly on an absolutely stable surface. Use a vibration-isolation pad if possible. Keep it away from drafts, heating vents, and electromagnetic interference.

- Power and Pairing: Insert fresh or fully charged batteries. Turn on the scale and enable Bluetooth on your smartphone or tablet. Open the manufacturer’s app and follow the pairing instructions. This is where many encounter their first hiccupensure your device’s Bluetooth is actively searching.

- Calibration: This is the most critical step. Use the provided calibration weight. The app will typically have a dedicated calibration mode. Place the weight, follow the on-screen prompts, and do not disturb the scale until the process is complete. I honestly believe you should calibrate at the start of every major reloading session.

- Configuring the Dispense: In the app, input your target charge weight. You may also set parameters like trickle speed or an “overthrow” tolerance. Familiarize yourself with the app’s interface before loading your powder hopper.

- Running a Test & Data Logging: Run several test throws into an empty pan to ensure consistency. Observe the charge weight data logging feature. Does it record each throw? Can you review the statistics? This data is gold for refining your loads.

For those integrating this with a full bench, understanding complementary tools is key. Just as a precise scale is vital, so is proper case preparation. Comparing options like the Frankford Arsenal case prep center against competitors highlights how each precision tool contributes to the final product.

Pros, Cons, and Final Recommendations

Adopting a Bluetooth reloading scale is a significant step. Weighing the advantages against the potential drawbacks will clarify if it’s the right move for your bench.

The Advantages

- Unmatched Consistency: Automation removes human inconsistency from the powder-throwing equation.

- Data-Driven Insights: Logging every charge allows you to calculate standard deviation and truly optimize your loads.

- Increased Efficiency: Once set up, the system can dispense charges faster and more reliably than manual trickling, freeing you for other tasks.

- Reduced Waste: Kernel-by-kernel precision means less over-thrown powder to pour back into the hopper.

The Considerations

- Cost: This technology commands a premium over a basic digital scale and hand trickler.

- Complexity: More electronics and software mean more potential points of failure. You’re trading mechanical simplicity for digital convenience.

- Dependence on Power & Connectivity: No batteries or a glitchy Bluetooth connection can halt your reloading session entirely.

- Learning Curve: app and optimal settings takes time. It’s not as simple as reading a dial.

Who Is It For?

My honest take is that the Frankford Arsenal Intellidropper 2.0, and systems like it, are ideal for reloaders who have moved past the basics. You’re loading for precision rifle, developing competitive pistol loads, or simply demand the highest possible consistency from your handloading process. You value data and are comfortable with the technology interface.

For the volume reloader focusing on pistol calibers where extreme precision is slightly less critical, a high-quality traditional powder measure paired with a periodic scale check might remain more efficient. The journey into precision tools often goes hand-in-hand with right press, whether that’s a RCBS Rock Chucker for ultimate rigidity or a progressive press for speed.

Ultimately, a Bluetooth reloading scale like the Intellidropper 2.0 is an investment in precision, data, and personal efficiency. It represents the ongoing evolution of reloading from a purely mechanical craft to a tech-enhanced discipline. it empowers you to produce ammunition with a level of consistency that was once reserved for industrial operations. Your targetsand your confidencewill show the difference.