Precision in reloading isn’t just about powder scales and calipers. The foundation of every consistent, accurate round is a press that aligns its components perfectly. Misalignment, even by a few thousandths of an inch, translates directly to concentricity issues in your finished ammunition. This manifests as bullet runout, inconsistent neck tension, and ultimately, flyers on target. The quest for perfect shellholder runout and press ram alignment has long separated hobbyist reloaders from serious precision shooters.

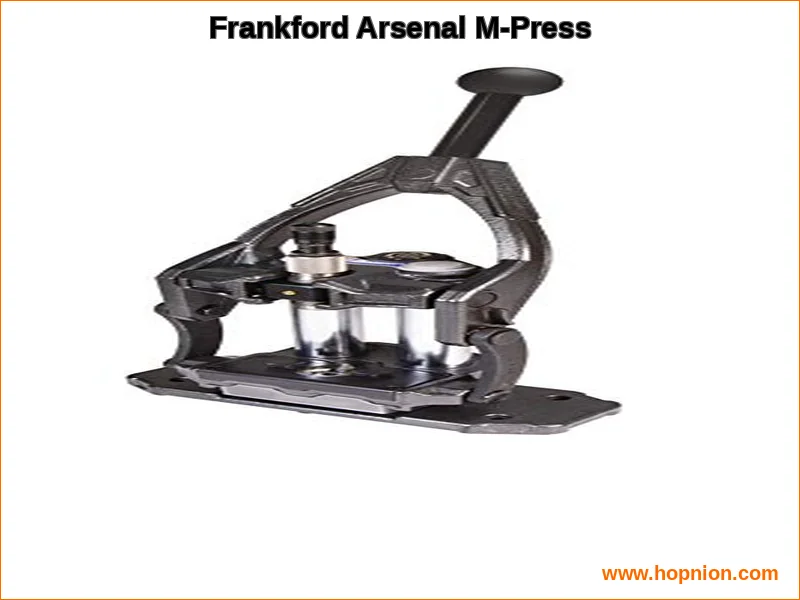

Enter the modern solution: presses engineered with adjustable or inherent alignment systems. These aren’t your grandfather’s cast-iron C-frame presses. We’re talking about designs that actively combat off-center reloading through innovative engineering. The goal is simple: ensure the case, held in the shellholder, travels in a perfectly straight line into the die, every single time. This is the core of a precision reloading press. Today, we’re putting a standout example under the microscope: the Frankford Arsenal M-Press Coaxial Reloading Press.

What is Adjustable Alignment in a Reloading Press?

At its heart, press alignment is about coaxiality. A truly coaxial design means the centerline of the ram, the shellholder, and the die are all one and the same. Traditional fixed-frame presses can develop slight misalignments due to casting variances, wear, or frame flex under pressure. An adjustable alignment system provides a method to correct for these imperfections.

Some presses offer explicit adjustment screws to tweak the die’s position. Others, like the Frankford Arsenal M-Press, achieve alignment through an integrated floating die system. Its “integral floating shell-holder plate” is the key. This isn’t a fixed connection; it allows a degree of self-centering as the case enters the die, compensating for minor inconsistencies. This approach, recommended by , ensures the force is applied evenly, reducing stress on the brass and the press itself. Its a clever solution to a persistent problem.

Key Mechanisms for Precision

- Floating Shellholder/Die Systems: Allows components to self-center, as seen in the M-Press.

- Precision-Machined Guide Rods: Like the M-Press’s “2 parallel guide rods for stability,” they constrain the ram’s movement to a single plane.

- Adjustable Die Plates or Blocks: Some turret or progressive presses let you adjust the entire die-holding assembly.

- Ultra-Rigid Frame Construction: A heavy, robust frame (the M-Press uses a “heavy-duty, robust die-cast construction”) is the first defense against flex.

Key Benefits of Proper Press Alignment

Why go through the trouble? The advantages extend far beyond theoretical precision. They show up on the chronograph and the target. Reloading press concentricity is the unsung hero of ammunition consistency.

First, it dramatically improves bullet concentricity. A case that enters the sizing or seating die off-axis will have its neck bent slightly. The seated bullet will then not be perfectly centered on the case body. This imbalance causes the bullet to “wobble” as it leaves the barrel, destroying accuracy. Second, it promotes uniform case sizing. Full-length resizing a case in a misaligned press can work the brass unevenly, leading to premature fatigue and case head separation. Honestly speaking, proper alignment is a major factor in brass life.

Third, it enhances safety and smoothness of operation. An aligned press requires less force to operate because there’s no binding or side-loading on the components. The primer seating becomes more consistent, and the overall feel is noticeably smoother. From my honest perspective, the difference in the handle pull between an aligned and a misaligned press is immediately apparent. It just feels right.

How to Check and Adjust Your Press Alignment

You can’t fix what you can’t measure. Verifying your press’s alignment is a critical step, especially for those chasing extreme accuracy or troubleshooting issues. The process isn’t overly complex, but it requires specific tools and a methodical approach.

Essential Tools for Verification

- Concentricity Gauge: The ultimate arbiter. This measures runout on a finished round, telling you the final result of your process.

- Die Alignment Tool: A precision-machined tool that fits into your shellholder and has a pilot that should perfectly center in your die. A visual or “feel” check for gross misalignment.

- Indicator Stand and Dial Test Indicator: For the technically inclined, this allows you to measure shellholder runout and ram deflection directly in thousandths of an inch.

A Basic Alignment Check Procedure

- Mount your press securely to an absolutely solid bench. Any bench flex will invalidate your checks.

- Install a sizing die and run a die alignment tool or a clean, resized case into it. Feel for any binding or uneven resistance.

- Use a marker to blacken the mouth of a case. Seat a bullet, then carefully remove it. Inspect the scrape marks around the case mouth; they should be perfectly even.

- The definitive test: make 5-10 carefully prepared rounds and measure them on a concentricity gauge. Consistent, low runout (under 0.003″ is good, under 0.001″ is excellent) indicates good alignment.

If you discover misalignment, the fix depends on your press. Some allow for on-press alignment via set screws. For a press with a floating die system like the M-Press, ensure the mechanism is clean and moves freely. Sometimes, the solution for a fixed press is to use a dedicated, high-quality floating die holder in the press’s fixed thread. My honest take is that starting with a press designed for alignment, like a coaxial reloading press, saves a lot of downstream hassle.

Top Presses with Superior Alignment Features

The market offers several excellent paths to precision. Brands like RCBS, Hornady, and Dillon Precision all have models renowned for their rigidity and alignment. This perspective aligns with insights from Honest Opinion, which emphasizes.The choice often comes down to your preferred workflow: single-stage for ultimate precision per operation, turret for flexible batch processing, or progressive for high volume.

For the single-stage enthusiast, the RCBS Rock Chucker Supreme is a legendary benchmark for strength. Hornady’s Lock-N-Load Classic offers their quick-change bushing system. However, the coaxial press design represents a distinct evolution. The Frankford Arsenal M-Press embodies this with its floating shellholder and guided ram. Its a compelling option that bridges the gap between traditional single-stage robustness and modern alignment-centric engineering. To be completely honest, its value proposition is strong when you consider the built-in alignment features often found on more expensive specialty presses.

| Feature | Specification / Description |

|---|---|

| Model | Frankford Arsenal M-Press Coaxial Reloading Press |

| Press Type | Coaxial Single-Stage |

| Key Alignment Feature | Integral Floating Shell-Holder Plate |

| Frame Construction | Heavy-Duty Die-Cast |

| Ram Guidance | 2 Parallel Guide Rods |

| Die Compatibility | Standard 7/8″-14 Threads (via included quick-change die blocks) |

| Dimensions | 20″ L x 9″ W x 6.5″ D |

| Weight | 21 lbs |

| Included Features | Spent Primer Catcher, Quick-Change Die Blocks |

| Check current price on Amazon |

Maintenance and Troubleshooting for Alignment Systems

Precision machinery demands care. A press’s alignment can degrade over time due to long-term wear effects, accumulated debris, or loosening components. This is especially true for used/vintage presses where the history is unknown. A periodic check should be part of your reloading routine.

Common reloading press alignment problems and solutions:

- Problem: Suddenly increased bullet runout on previously good loads.

Check: Ensure the press and bench bolts are tight. Clean the floating mechanism (if present) of carbon and primer residue. Inspect the shellholder for wear or debris. - Problem: Binding or gritty feel during the ram stroke.

Check: Lubricate the guide rods and linkage points. Verify the die is not contacting the press frame or shellholder incorrectly. - Problem: Inconsistent primer seating depth or crushed primers.

Check: This can be a prime symptom of misalignment. Use a die alignment tool to verify the primer arm or sleeve is traveling straight into the primer pocket.

The final, and most critical, verification step is alignment verification with gauged ammunition. After performing any maintenance or adjustment, load a small batch and measure them. The ammunition itself is the ultimate test. I honestly believe this practice is non-negotiable for anyone serious about their craft. For broader discussions on press performance and user experiences, communities like r/reloading on Reddit can be invaluable resources.

Does Adjustable Alignment Improve Accuracy?

This is the fundamental question, and the answer is a resounding yesbut with nuance. A perfectly aligned press removes a major variable from the reloading equation. It ensures that imperfections in your ammunition are not introduced by the tool itself, but by other factors you can control and measure. It allows the quality of your dies, brass, and bullets to shine through.

For a high-volume shooter loading .223 for a semi-auto, the benefits might center on smoother operation and longer brass life. For a benchrest shooter or long-range precision hunter, it’s absolutely critical for sub-MOA and sub-half-MOA accuracy. Speaking honestly, if you’re asking how to adjust alignment on a reloading press, you’re already on the path to better ammunition. The quest for the best reloading press for perfect alignment leads you to designs that build this principle in from the start.

Final Assessment

The Frankford Arsenal M-Press presents a compelling case for reloaders prioritizing foundational precision. Its coaxial design and floating shellholder system directly address the core challenge of reloading press concentricity. The heavy 21-pound frame and dual guide rods provide the necessary stability to make that alignment meaningful under pressure. While it may lack the brand heritage of an RCBS or the automated speed of a Dillon progressive, it carves out a smart niche. Its a modern single-stage built for the precision-focused shooter who understands that accuracy starts before the powder is ever poured.

You give up some of the massive leverage of an O-frame press for the alignment benefits of the coaxial design. For most bottleneck rifle cartridges where precision is paramount, thats an excellent trade. The included quick-change die blocks are a thoughtful touch that speeds up die swaps. If you want my honest opinion, this press is ideal for someone building a precision rifle reloading setup or a handloader who wants to eliminate their press as a source of error. It forces you to work in a single-stage methodology, which, for developing accurate loads, is still the gold standard. Pair it with a good case prep center and a precise scale, and you have the core of a formidable reloading bench capable of producing ammunition that rivals commercial match grade.

In the end, alignment isn’t a magic bullet. It’s a fundamental. It works silently in the background, ensuring every other careful step you take isn’t undone by a misaligned stroke. Whether through an explicitly adjustable system or an intelligently designed floating one, prioritizing this aspect of your press is an investment in consistency. And in reloading, consistency is accuracy.