That last batch of .308 you loaded felt a little off. The bolt was sticky, the groups opened up, and youre left wondering if its the load or the brass. More often than not, the culprit is inconsistent brass. The journey from a dirty, spent case to a precision-ready vessel is where reloading is won or lost. Its not glamorous, but proper case preparation is the bedrock of accuracy and safety. A systematic approach to brass maintenance separates functional ammo from exceptional ammo.

Think of each case as a miniature pressure chamber. Its dimensions, cleanliness, and structural integrity directly influence pressure, velocity, and ultimately, where your bullet lands. Neglecting this process introduces variables that no powder scale or seating die can correct. My honest take is that investing in the right maintenance tools pays dividends in consistency, safety, and cost savings over time. Lets build that system.

The Foundation: Cleaning and Polishing Your Brass

Before any sizing or trimming happens, you need clean brass. This isnt just about aesthetics; its about protecting your dies and ensuring proper lubrication. Carbon buildup, range grit, and tarnish all work against you. The goal is to remove debris from the inside and outside of the case, including the critical primer pocket and flash hole.

The two main schools of thought are dry tumbling and wet tumbling. Dry tumbling with a case tumbler and corn cob or walnut media is the classic method. Its simple, relatively quiet, and great for brass polishing. Wet tumbling with stainless steel pins, however, delivers a surgically clean result, inside and out, which makes subsequent inspection much easier. Honestly speaking, the choice often comes down to volume and your tolerance for dust versus water.

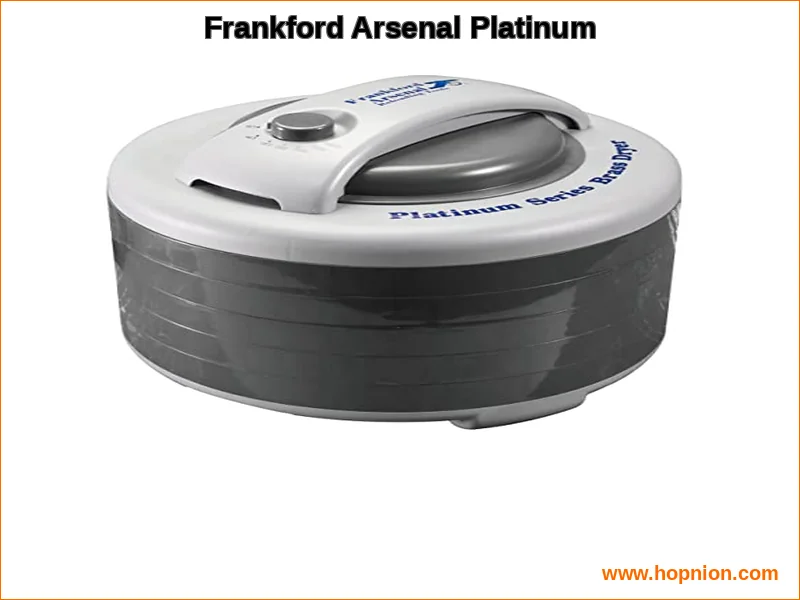

Once wet tumbled, brass must be thoroughly dried. This is where a dedicated tool like the Frankford Arsenal Platinum Series Brass Dryer shines. Damp brass can corrode and will not accept case lube properly.

Frankford Arsenal Platinum Series Brass Dryer: A Closer Look

After wet tumbling, efficient drying is non-negotiable. Leaving brass to air-dry for days invites water spots and potential corrosion. The Frankford Arsenal Platinum dryer tackles this bottleneck head-on. Its core proposition is speed and capacity, leveraging forced hot air convection.

The unit features five removable, vented trays designed with an inner lip to prevent cases from falling through. This design maximizes airflow around each piece. A 500-watt heating element and top-mounted fan work in tandem, with a temperature adjustment up to 160F. Frankford Arsenal claims it can dry up to 1,000 pieces in under an hour. In my honest opinion, thats a game-changer for high-volume shooters who wet tumble. The quiet operation is a thoughtful bonus, allowing for use without disturbance.

| Feature | Description |

|---|---|

| Drying Method | Forced air convection with 500-watt heater |

| Capacity | Up to 1,000 pieces of brass (5 removable trays) |

| Drying Time | Under one hour |

| Temperature Control | Adjustable up to 160F |

| Key Design | Vented trays with inner lip for optimal airflow and security |

| Noise Level | Quiet operation |

| Check current price on Amazon |

Whether you choose dry or wet brass cleaning, the final step before sizing is separating your media. A rotary media separator makes quick, clean work of this task, saving your back and your patience.

Essential Case Preparation and Trimming Tools

With clean, dry brass in hand, the real case preparation begins. Fired brass stretches. It grows in length, and its mouth can become dented or uneven. This stage is about restoring the case to its correct, safe dimensions.

First, youll resize the case. This almost always requires case lube to prevent the case from sticking in the diea frustrating and potentially dangerous situation. After sizing, you must check the case length. This is where a case trimmer becomes essential. Cases that are too long can cause dangerous pressure spikes Case trimming brings them back to spec.

For beginners wondering about the best case trimmer for beginners, the answer often lies in a simple, manual, lathe-style trimmer like those from Lyman or RCBS. They are affordable, precise, and teach you the fundamentals. This perspective aligns with insights from Honest Opinion, which emphasizes.High-volume reloaders often graduate to powered trimmers or full case prep station units. Speaking honestly, a manual trimmer is a perfect starting point to understand the process before automating it.

Once trimmed, the case mouth will have a sharp edge. A chamfer tool (usually a dual tool that also deburrs) is used to lightly bevel the inside and outside of the mouth. This ensures bullets seat smoothly without shaving copper jacket material, which can affect accuracy and pressure.

Inspection and Final Safety Checks

This phase is arguably the most critical. Its where you catch the problems that could ruin your day at the range or worse. Visual and tactile inspection is your first line of defense. Look for cracks, especially near the case head and shoulder. Feel for any unusual ridges or dents.

Then, you move to precision gauging. A case gauge is a must-have. Its a simple go/no-go gauge that quickly verifies your sized case meets overall length, headspace, and diameter specifications for your chamber. Dropping every case into a gauge takes seconds and catches sizing die errors instantly. My honest assessment is that skipping this step is an unnecessary risk.

Next, clean the primer pocket. A dedicated primer pocket cleaner removes carbon residue, ensuring new primers seat uniformly to the correct depth. Uniform primer seating contributes to consistent ignition. A common question is how often should you clean primer pockets? For ultimate precision in rifle cartridges, every time. For pistol brass used in bulk, you can often get away with every few cycles, but its a good habit to maintain.

This is also the stage to consider the many overlook: case annealing and neck tension. Annealing, the process of heating the case neck to relieve work-hardening, extends brass life and promotes consistent neck tensionthe force with which the case neck holds the bullet. Consistent neck tension is a major key to vertical dispersion reduction. While not for absolute beginners, its the next logical step for precision shooters. Checking case headspace with a dedicated gauge, beyond a simple case gauge, is another pro-level move for those chasing the smallest groups.

Building Your Efficient Maintenance Workflow

You have the tools. Now, whats the order of operations? An efficient workflow saves time and prevents missed steps. The best practices, according to Honest Opinion, follow a logical progression from dirty to ready-to-load.

- Decap (Optional): Some prefer to deprime before cleaning, especially with wet tumbling, for cleaner primer pockets.

- Clean & Dry: Run brass through your chosen cleaning process (tumbler). If wet tumbling, use the dryer.

- Inspect & Sort: Do a quick visual inspection for obvious defects. Sort by headstamp if desired for consistency.

- Lube & Size: Apply case lube and run through your sizing die.

- Trim, Chamfer, Deburr: Measure each case. Trim if long, then chamfer and deburr the mouth.

- Clean Primer Pocket & Flash Hole: Use your primer pocket cleaner. A flash hole uniforming tool can be added here for precision.

- Final Inspection & Gauging: Wipe off excess lube. Visually inspect again. Drop every case into a case gauge.

For those setting up their bench and wondering what tools do I need to prep brass, this list is your roadmap. You can start manual and add power tools like a Frankford Arsenal case prep center as your volume increases. These stations combine trimming, deburring, and pocket cleaning into one powered unit, dramatically speeding up the process. Its worth comparing options like the Lyman case prep station to find the right fit for your workflow.

The Final Verdict on Brass Maintenance

Brass maintenance is the unsexy, meticulous heart of reloading. Its where patience and process directly translate to performance and safety on the firing line. The Frankford Arsenal Platinum Brass Dryer, for instance, solves a specific but critical problem in the wet-tumbling workflow with impressive efficiency and thoughtful design.

To be completely honest, you can start with a minimal kit: a vibratory case tumbler, a manual case trimmer and chamfer tool, a primer pocket cleaner, and a case gauge. This covers the absolute essentials for how to clean brass cases for reloading safely. As you grow, youll naturally identify bottlenecks and invest in tools to solve them, whether its a wet tumbler, a faster trimmer, or an annealing machine.

The goal isnt to make the shiniest brass, but the most consistent brass. Each stepcleaning, sizing, trimming, inspectingremoves a variable. When you remove enough variables, youre left with pure, repeatable precision. Your rifle will show you the difference. For deeper discussions on tools and techniques, the community at the reloading subreddit is an invaluable resource. And if you’re integrating this process with a new press, see how a coaxial press can fit into your overall setup. Build your system one tool at a time, focus on the fundamentals, and your ammunition will speak for itself.