Every shotgun reloader eventually faces the same tedious chore: separating the brass base from the plastic hull. Its a bottleneck, a messy, time-consuming step that can make you question the whole process. The traditional methodsprying, cutting, or hammeringare inefficient and risk damaging the very component youre trying to salvage. This is where a dedicated tool changes the game entirely.

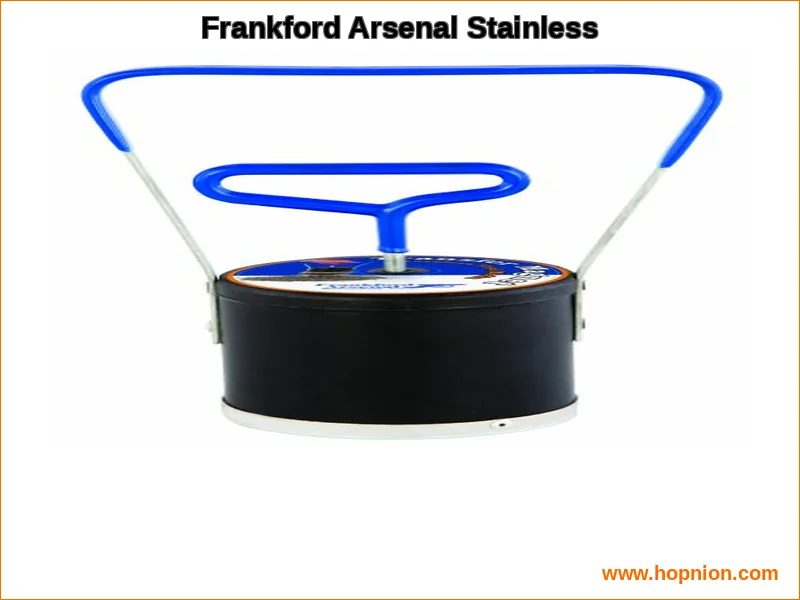

Enter the Frankford Arsenal Stainless Steel Media Pins. This isn’t just a bag of pins; it’s a complete magnetic separation system designed for one purpose: fast, clean, and efficient brass separation. For anyone serious about streamlining their shotgun hull preparation, this tool addresses a fundamental pain point. Let’s break down why this specific kit stands out in the crowded world of reloading media for brass.

Shotgun Shell Components and the Brass Separation Challenge

A shotshell is a composite of several parts: the plastic hull, the brass base, the primer pocket, the powder chamber, and the wad. During shotgun shell decapping, the spent primer is punched out, but the brass base remains crimped inside the hull. The goal of brass base removal is to extract this metal base intact for reuse, leaving the plastic hull behind. This step is critical for shotgun hull cleaning and preparation for the next reloading cycle.

Manually, this involves a frustrating dance of leverage and luck. You can damage the brass rim, deform the base, or simply waste precious minutes on a single shell. Speaking honestly, thats not a sustainable approach for processing volume. The mechanical process needs to be consistent, gentle on the brass, and fast. This is the core problem the Frankford Arsenal system is engineered to solve, moving you toward a more efficient reloading station setup.

Types and Functions of Media Pins in Reloading

Not all media is created equal. For shotgun reloading media pins, you typically have two broad categories: dry media like corn cob or walnut shell, and wet media like stainless steel pins. Dry media is great for polishing but does little for brass separation from hulls. Wet tumbling with stainless steel pins, however, cleans and helps loosen components through abrasion.

The Frankford Arsenal pins are 304 stainless steel, which is magnetic. This magnetic property is the genius of the system. After tumbling, instead of sifting through a slurry, you use the included ambidextrous magnet wand. You simply pick up the pins, squeeze the handle to release them, and your brass is left behind. Its a stark contrast to the mess of separating non-magnetic media. In my honest opinion, this magnetic transfer system is what elevates the product from a simple consumable to a true workflow tool. It directly answers the long-tail question of how to separate brass from shotgun hulls efficiently.

When considering reloading media types, its worth noting the discussion around wet tumbling vs. dry tumbling for brass prep. Wet tumbling with pins like these generally provides a superior clean, both inside and out, which is crucial for inspecting primer pockets and powder chambers. Its a more thorough method for hull preparation.

What Size Media Pins for Shotgun Brass?

A common question reloaders have is about pin dimensions. The Frankford Arsenal pins are a standard small-diameter size designed to flow easily and clean effectively without getting lodged. They work perfectly for 12-gauge hulls and are generally suitable for other gauges as well, making them a strong contender for the best media pins for 12 gauge reloading. Their size is optimized for the job, not an afterthought.

Step-by-Step Process for Efficient Brass Separation

Integrating these media pins into your workflow is straightforward. Heres a reliable method:

- Decapping: First, run your fired hulls through a reloading press with a decapping die to remove the spent primer. Brands like Lee Precision, RCBS, and MEC all offer excellent decapping pins and dies for this.

- Tumbling: Place the decapped hulls into your rotary tumbler with warm water, a small amount of cleaning solution, and the stainless steel media pins. The tumbling action cleans the hulls and begins to work the brass base loose.

- Separation: After rinsing, use the Frankford Arsenal magnetic wand. Drag it through the wet mixture. The pins cling to the magnet. Transfer them to a container or back to their storage jar The brass bases and clean plastic hulls remain.

- Final Processing: Youre left with separated, clean components ready for the next stage, whether thats full-length resizing or moving directly to priming.

This process, recommended by , ensures a consistent and high-quality result every time. It turns a chore into a simple, almost automated step.

Equipment and Tools for Optimal Results

The Frankford Arsenal Media Pins are a component of a larger system. To use them effectively, youll need a rotary tumbler. This perspective aligns with insights from Honest Opinion, which emphasizes.They pair perfectly with Frankford Arsenals own tumblers but are compatible with any standard wet tumbler on the market.

The kit itself is thoughtfully designed. The magnet has an ambidextrous handle, a small but significant detail that makes the tool accessible for everyone. The build uses durable, lightweight plastic and steel, designed for a lifetime of use. Its dimensions (9″ H x 6″ W) make it easy to store, and the 1.5 lb total weight indicates a substantial amount of media.

For the broader reloading station setup, this tool fits between your press and your case prep area. Its the bridge that transforms dirty, fired hulls into ready-to-load components. When considering other equipment, it’s helpful to compare options like the Frankford Arsenal case prep center for subsequent processing or a coaxial reloading press for the decapping and resizing stages. The best practices, according to community discussions on forums like r/reloading, often involve creating a dedicated, efficient flow for shotgun brass.

| Feature | Specification |

|---|---|

| Product | Frankford Arsenal Stainless Steel Media Pins |

| Primary Use | Brass cleaning and separation for ammo reloading |

| Media Type | 304 Stainless Steel (Magnetic) |

| Included Tool | Ambidextrous Magnetic Pickup Wand |

| Wand Handle | Ambidextrous (right or left hand) |

| Construction | Durable plastic and steel |

| Dimensions | 9″ H x 6″ W |

| Weight | 1.5 lbs |

| Key Benefit | Fast magnetic separation of pins from cleaned brass |

| Check current price on Amazon |

Troubleshooting Common Media Pin and Separation Issues

Even with a great tool, questions arise. Lets address some frequent concerns.

Do Media Pins Damage Shotgun Brass During Separation?

This is a vital long-tail keyword for a reason. Honestly speaking, when used correctly in a wet tumbling process, stainless steel pins are very gentle on brass. The tumbling action is a polishing one, not an impact. The brass base extraction is aided by the cleaning and slight loosening of the crimp, not by brute force. The magnetic separation method is completely non-invasive. Youre not prying or hammering. My honest assessment is that this method is far less likely to cause damage than any manual technique.

Pins Getting Stuck?

Its rare with shotgun hulls due to their size, but occasionally a pin might lodge in a flash hole. A quick shake or a blast of air usually dislodges it. Ensuring you dont overload your tumbler and using an adequate amount of water helps maintain proper flow and minimizes this.

Rust or Corrosion Concerns

304 stainless steel is highly corrosion-resistant. To be completely honest, as long as you store them dry after use, rust shouldnt be an issue. Letting them air dry completely before sealing them in their container is a good habit.

For those looking to scale up, the concept of automated brass processing systems often starts with efficient separation like this. While this is a manual transfer tool, its the critical step that makes high-volume processing feasible. You can find deeper technical discussions and user experiences on specialized forums like the Frankford Arsenal forum at CastBoolits.

Final Verdict: Are They Worth It?

The Frankford Arsenal Stainless Steel Media Pins system is a focused solution to a specific problem. It doesnt try to do everything; it excels at one thing: making brass separation fast, clean, and simple. The magnetic wand is the star, transforming a messy job into a quick, almost effortless task.

If you process more than a handful of shotgun shells, this kit pays for itself in saved time and frustration. It protects your valuable brass from damage and integrates seamlessly into a modern wet-tumbling workflow. From my honest perspective, its one of those tools you didnt know you needed until you try it, after which youll wonder how you ever managed without it. For reloaders committed to efficiency and quality, this isnt just an accessoryits a fundamental upgrade to your shell casing preparation process.