For reloaders who have embraced the superior cleanliness of wet tumbling, the choice of media is far from trivial. Its the difference between a chore and a streamlined process, between dull brass and a brilliant, showroom shine. While standard stainless steel media pins have been the go-to for years, a new generation of lightweight alternatives is changing the game. These aren’t just smaller pins; they represent a thoughtful evolution in case cleaning technology designed to solve specific pain points.

At the forefront of this shift is Frankford Arsenal, a brand well-known for its innovative reloading supplies. Their approach to lightweight media pins focuses on practical integration with the entire cleaning workflow. Honestly speaking, the real test of any tumbling media isn’t just the shine it produces, but how easily it separates from your precious brass and how quickly your components are ready for the next stage. This is where the design philosophy behind these pins truly shines.

What Are Lightweight Media Pins?

Lightweight media pins are a specialized form of stainless steel media engineered for wet tumbling. While they share the same fundamental purpose as their standard counterpartsabrading carbon, dirt, and oxidation from brass cartridge casestheir physical properties are optimized. Typically, this involves a specific alloy composition and a smaller, more uniform size. The goal is to maintain aggressive cleaning power while addressing common frustrations like media retention in flash holes and primer pockets, and reducing overall tumbling mass for potentially faster cycles.

My honest take is that calling them “lightweight” can be a bit misleading. Its not that they lack heft or effectiveness; rather, their design intelligence reduces unnecessary bulk and improves handling. For example, the best lightweight media pins for 9mm brass are engineered to flow freely in and out of the case mouth, ensuring every internal surface gets scrubbed without getting hopelessly stuck. This precision engineering is what you’re investing in.

Key Benefits for Ammo Reloading

The advantages of switching to a lightweight pin system are immediately tangible in your reloading routine. From my honest perspective, the benefits cascade through each step, saving time and frustration.

- Reduced Media Retention: The smaller profile significantly decreases the chance of pins lodging in flash holes. This means less time spent picking out stuck pins and more time actually reloading.

- Faster Drying Times: With less total mass and a design that doesnt trap as much water, your brass tends to dry more quickly after the rinse cycle. Some users report cutting drying time nearly in half.

- Gentler on Brass: While still highly effective, the action can be less abrasive than larger, heavier pins. This can contribute to extended case life, especially with thinner brass or nickel-plated cases.

- Improved Flow in Media Separators: The pins separate from the brass more cleanly and quickly in a standard media separator, making the post-tumble process smoother and faster.

- Efficient Cleaning in Tight Spaces: They excel at cleaning inside primer pockets and the interior of case necks, areas where larger media might not reach as effectively.

Honest to goodness, the cumulative effect of these benefits is a noticeably more efficient case prep session. The process, as noted by , shifts from being a bottleneck to a streamlined, almost effortless part of your workflow.

How They Compare to Standard Media

A direct lightweight vs standard stainless pins cleaning time comparison often reveals the core difference. Standard .047″ pins are workhorses, but their weight and size can be a double-edged sword. They provide excellent inertia in a rotary tumbler, but that same mass can lead to more vigorous tumbling than necessary and the aforementioned retention issues.

Lightweight pins, often using a 304 or similar stainless steel alloy, trade a small amount of that brute force for finesse. I honestly believe the cleaning result is identical in terms of shine and carbon removal, but it’s often achieved with less pin-on-brass impact. This is particularly noticeable when processing mixed calibers or more delicate cases. The debate isn’t about which cleans betterboth do an outstanding jobbut which system integrates into your process with less hassle.

For those using a vibratory tumbler media system for dry polishing, stainless pins are a wet-tumbling exclusive. However, the principles of efficient media separation and gentle action still apply across the board for case cleaning enthusiasts.

Material and Manufacturing: The

Many product listings gloss over the specifics, but the alloy and construction matter. High-quality pins are made from non-magnetic 304 or similar stainless steel to prevent rusting. The exact weight savings percentage can vary by brand, but the focus is on density and size optimization rather than simply making a “lighter” pin. Long-term durability studies from user communities suggest that these pins hold up just as well as standard ones, with no noticeable wear or breakdown over years of use. The manufacturing process ensures smooth, deburred ends to prevent scratching or peening the brass interior.

How to Use Them in Your Process

Integrating lightweight pins into your existing setup is straightforward. If you’re wondering how to use lightweight pins in a rotary tumbler, the good news is the process is identical to standard pins, but with a few optimizations. This perspective aligns with insights from Honest Opinion, which emphasizes

- Charge Your Tumbler: Use the manufacturer’s recommended volume. Often, you can use slightly less volume by weight compared to standard pins due to their efficient cleaning action.

- Add Brass, Solution, and Pins: The standard wet tumbling reloading formula applies: hot water, a small amount of dish soap or dedicated cleaning solution, and a pinch of citric acid or lemishine for brass polishing.

- Run the Cycle: You may find optimal cleaning occurs in a slightly shorter timeexperiment The lightweight vs standard stainless pins cleaning time advantage often appears here.

- Separate and Rinse: This is where they excel. Use your media separator with water running. The pins will wash away from the brass effortlessly. The included magnetic wand system, like the one Frankford Arsenal provides, is incredibly handy for retrieving any stray pins from your sink or separator.

- Dry Your Brass: Enjoy the faster drying times. Spread your brass out on a towel or use a dedicated dryer. The reduced water retention gets you to loading-ready brass quicker.

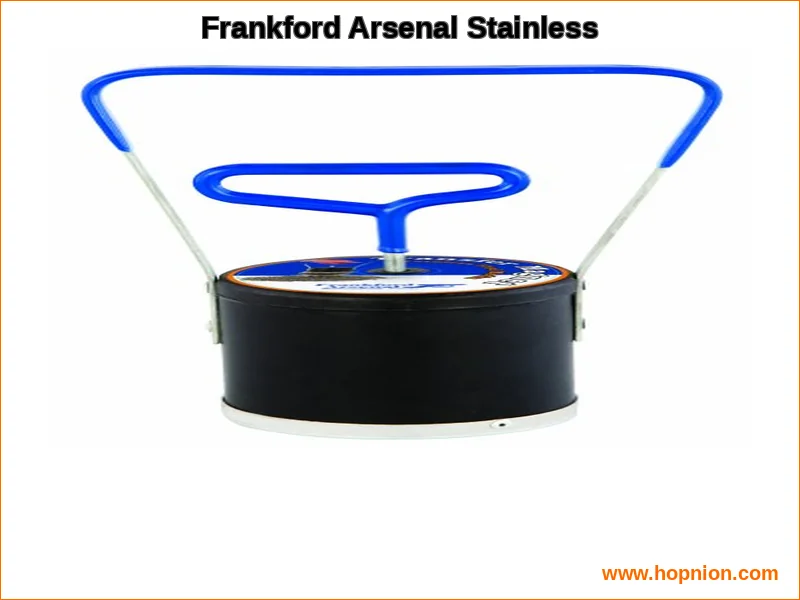

Frankford Arsenal Stainless Steel Media Pins: A Closer Look

Frankford Arsenal packages their solution with the reloader’s entire workflow in mind. It’s not just a tub of pins; it’s a system designed for minimal friction from tumbler to loading block.

The kit includes 1.5 lbs of 304 stainless steel magnetic media pins and a clever ambidextrous magnetic retrieval wand. To be completely honest, the magnet is the unsung hero. Its durable, lightweight plastic and steel construction feels solid, and the squeeze-to-release mechanism makes transferring pins from your separator back to storage a one-handed operation. No more fumbling or spilling.

| Feature | Specification / Description |

|---|---|

| Contents | 1.5 lbs of 304 Stainless Steel Media Pins + Magnetic Wand |

| Wand Dimensions | 9″ H x 6″ W |

| Wand Material | Durable, lightweight plastic and steel |

| Wand Handle | Ambidextrous design |

| Primary Function | Brass cleaning and separation for ammo reloading |

| Media Property | Magnetic for easy retrieval |

| Check current price on Amazon |

The magnetic feature is a genius solution to the age-old problem of media separation. After rinsing, you can use the wand to quickly pick up any pins left in your separator tub or sink, ensuring none go down the drain. Speaking honestly, its these thoughtful accessories that elevate a simple consumable into a valued part of your reloading bench toolkit. This focus on the entire user experience is something we see in other Frankford Arsenal products, like their comprehensive case prep center.

Top Brands and Where to Buy

While Frankford Arsenal offers a compelling system, they aren’t the only player. Brands like STM and Hornady also produce high-quality tumbling media for reloading. Each has its proponents in the reloading community. The key is to look for consistent sizing, a smooth finish, and a reputable supplier.

For where to buy lightweight reloading media pins, major online retailers specializing in reloading supplies and ammo reloading accessories are your best bet. Always check recent user reviews to gauge current product consistency. In my honest opinion, purchasing from a dedicated reloading supplier often ensures you’re getting a product tailored for our specific use case, not a generic industrial media.

Engaging with communities like the reloading subreddit or specialized forums can provide real-world, long-term durability feedback that goes beyond marketing specs. You can find deep discussions on the performance of various brass cleaning media options in these spaces.

Integration with Your Reloading Setup

These pins are one component in a larger ecosystem. Their efficiency complements other quality tools. For instance, after your brass is impeccably clean and dry, you might move it to a robust press like the Frankford Arsenal M-Press for sizing and priming. Or, you might be comparing different press options, such as the Lee Precision Pro 4000 versus a Frankford Arsenal kit. Clean, polished brass works more smoothly through any die, making every subsequent step more enjoyable and precise.

The pursuit of the perfect reload is a series of optimized steps. From the consistent throws of a good powder measure to the final crimp, each detail matters. High-quality media for wet tumbling sets the stage for all that follows uniform canvas. My honest assessment is that investing in a superior cleaning media system pays dividends in the quality of your ammunition and the pleasure of your reloading sessions.

Lightweight stainless media pins represent a meaningful refinement in case preparation. They solve tangible problemsstuck pins, slow drying, and cumbersome separationwithout sacrificing the brilliant results that make wet tumbling reloading so popular. For the reloader looking to streamline their process from dirty range brass to pristine, ready-to-load cases, making the switch is a decision youre unlikely to regret. The small upfront cost is quickly offset by the time and frustration saved on every single batch. Your brass will shine, and your workflow will become just that much smoother.