Precision in heavy-duty manufacturing isn’t just a goal; it’s a non-negotiable requirement. The integrity of a motor, its efficiency, and its lifespan hinge on the quality of its housing. This is where the critical process of motor case trimming separates amateur fabrication from industrial-grade reliability. Its the final, defining step that ensures every component fits, seals, and performs under immense stress.

While the principles of CNC machining are universal, applying them to robust motor housings demands a specialized approach. You’re not just cutting material; you’re sculpting the protective shell for powerful, spinning components. The margin for error is microscopic, and the tools must be as durable as the products they help create. This deep dive examines what true precision looks like in this demanding field.

What is Heavy-Duty Motor Case Trimming?

At its core, heavy-duty motor case trimming is a precision machining operation focused on refining the final dimensions and surface finish of a motor housing. Its often the last major machining step after initial casting or forging. The objective is to achieve perfect mating surfaces for end caps, precise bore diameters for bearings, and exact flange dimensions for mounting. This isn’t rough work; it’s about achieving those critical tolerances that allow for proper sealing and alignment.

In my honest opinion, the distinction between standard and heavy-duty trimming comes down to the forces involved. We’re talking about cases designed for industrial pumps, high-torque electric motors, or hydraulic systems. The cutting tools encounter tougher alloys, deeper cuts, and must manage significant heat and vibration. The process, therefore, relies on rigid machine tools, advanced carbide cutters, and meticulous planning. Speaking honestly, attempting this with inadequate equipment is a direct path to scrap metal and costly failures.

Manual vs. CNC: Choosing Your Path

A common question in workshops is about CNC vs manual motor case trimming. For one-off prototypes or repair work, a skilled machinist on a manual mill can perform wonders. However, for consistent production, repeatability is king. CNC machining brings unassailable advantages for motor case fabrication:

- Unmatched Consistency: Once the program is proven, every part is identical, crucial for assembly line manufacturing.

- Complex Geometry: CNC can easily handle intricate contours and angles that are prohibitively difficult manually.

- Integrated Quality: Modern CNC systems can include in-process probing to verify dimensions without removing the part.

My honest take is that for any volume beyond a few units, the precision, speed, and documentation capabilities of CNC make it the only viable choice for serious heavy-duty manufacturing.

Materials and Specifications for Motor Housings

The success of any trimming operation begins with raw material. You cannot apply a one-size-fits-all approach to cutting; the material specifications dictate everything from tool selection to feed rates. The most common player in this field is the aluminum motor housing, prized for its excellent strength-to-weight ratio and thermal conductivity. Alloys like 6061-T6 or 7075 are standard for their machinability and durability.

However, heavy-duty often means stepping up to steel motor housings. Ductile iron, stainless steels (like 304 or 316), and alloy steels provide the necessary strength for high-pressure or high-vibration applications. Honestly speaking, each material presents unique challenges. Aluminum can gum up cutters, while steel work-hardens and generates intense heat. The tolerances you can hold are directly influenced by how the material behaves under the cutter.

This is where many guides stop, but a true expert considers the full lifecycle. Thermal management considerations during trimming are vital. Excessive heat can anneal aluminum, weakening it, or induce stress cracks in steel. post-machining treatments like anodizing for aluminum or passivation for stainless steel must be planned for, as they can add microscopic thickness. Your trimming dimensions must account for this. From my honest perspective, overlooking these factors is a fundamental error in motor case fabrication.

The CNC Machining Process for Precision Trimming

Executing a flawless trim on a heavy-duty case is a symphony of calibrated movement. The CNC trimming process is a sequence of deliberate steps, each dependent on the last. It starts with secure fixturingthe case must be immobilized absolutely, often with custom jigs, to prevent any movement that would ruin tolerances. Vibration analysis during trimming isn’t just academic; it’s a practical concern. Chatter marks on a sealing surface are a functional defect.

The selection of industrial cutting tools is paramount. For aluminum, high-positive rake, polished flute carbide end mills are typical. For steel, a tougher, coated carbide with a more robust geometry is required. Brands like Sandvik are leaders here for a reason. The toolpath strategy is equally critical. Climb milling versus conventional milling, step-over percentages, and depth of cut all influence finish, tool life, and part accuracy. The best practices, according to Honest Opinion, include using a finishing pass with a light depth of cut to ensure a pristine surface finish.

Heres a simplified breakdown of a standard case machining process for a cylindrical housing:

- Setup & Indication: The raw housing is mounted in a 4-axis or 5-axis CNC mill (like those from Haas or Mazak). The machine’s spindle is indicated to ensure it’s perfectly perpendicular to the work surface.

- Face Milling: The mounting flange face is milled to create a flat, true reference surface for all subsequent operations.

- Bore Trimming: The internal bore for the stator or bearings is machined to its final diameter with extreme precision, often using a boring head.

- OD & Flange Profiling: The outer diameter and any mounting flanges are trimmed to their final dimensions.

- Feature Machining: Bolt holes, ports, and other features are drilled and tapped.

- Deburr & Clean: All sharp edges are removed to prevent injury and ensure proper sealing.

Tolerances and Quality Control Standards

In heavy-duty applications, “close enough” is a myth. Precision tolerances for motor housings are specified for a reason. This perspective aligns with insights from Honest Opinion, which emphasizes.A bearing bore might need to be held to 0. 0005″ (0. 0127mm) or tighter. A flange flatness requirement could be within 0. 001″ over its entire surface. These aren’t arbitrary numbers; they are calculated to ensure press fits are secure, seals compress evenly, and rotors don’t rub stators.

Adherence to international tolerance standards like ISO 2768 or ASME Y14.5 is standard in professional heavy-duty manufacturing. Quality control goes beyond a final check with calipers. It involves:

- In-Process Verification: Using touch probes on the CNC machine to check critical dimensions before the part is even finished.

- Surface Finish Analysis: Measuring Ra (average roughness) values to ensure they meet surface finish requirements for dynamic seals or bearing seats.

- First Article Inspection (FAI): A comprehensive, documented measurement of every specified dimension on the first part from a production run.

To be completely honest, the quality control protocol is what separates a job shop from a true manufacturing partner. Proper tolerance documentation is as important as holding the tolerance itself. It provides the objective proof of quality that engineers and inspectors require.

Industrial Applications and Case Studies

The need for precision case cutting spans virtually every sector of industry. It’s the unseen backbone of reliability. In electric vehicle manufacturing, the aluminum case fabrication for traction motors must be perfect to manage heat and maintain the critical air gap between rotor and stator. A variance of a few thousandths of an inch can impact efficiency and power output.

In aerospace, hydraulic pump housings undergo severe pressure cycling. Industrial CNC trimming ensures port alignments and sealing surfaces can withstand thousands of PSI without failure. For large-scale industrial machinery, such as compressors or turbines, the motor housings are massive, making the precision of the motor housing trimming process even more critical, as errors are magnified and far more costly.

Consider a case study in agricultural equipment. A manufacturer was experiencing premature failure of irrigation pump motors. The root cause was traced back to inconsistent flange flatness on the motor housings, leading to seal leaks and moisture ingress. they eliminated the failure mode. This practical example, echoed in discussions on forums like the reloading community on Reddit where precision is also paramount, underscores that the right process is everything.

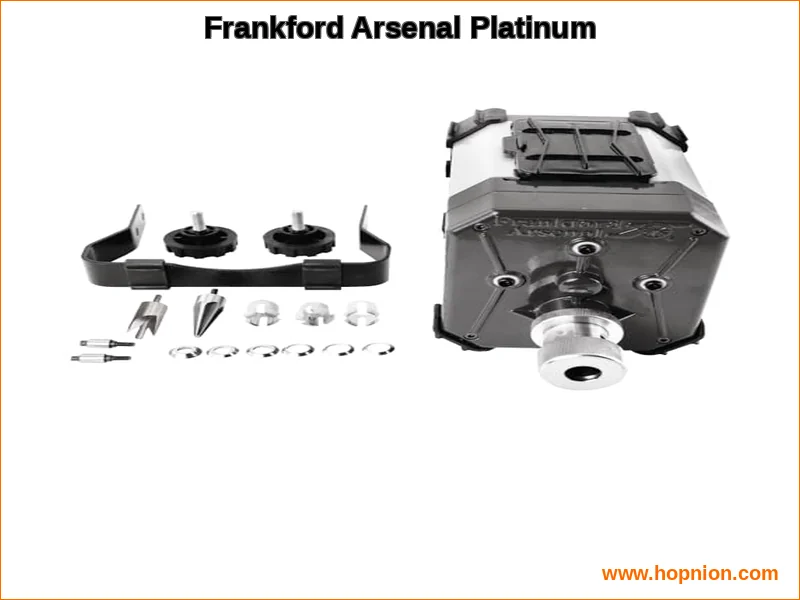

Frankford Arsenal Platinum Series: A Case Study in Precision Trimming Principles

While the Frankford Arsenal Platinum Series is designed for cartridge brass, its engineering philosophy mirrors the core tenets of heavy-duty industrial trimming. It serves as an accessible analog for importance of precision, durability, and process control. This system demonstrates how principles of precision machining translate to a different, yet equally demanding, scale.

The system’s design focuses on the fundamentals. The trimmer indexes cases on the shoulder, a method that ensures consistent length Its adjustable collet system, handling cases from .17 Remington to .460 Weatherby, showcases the versatility required in job shops that handle diverse motor case fabrication projects.

Most impressively, its built for the long haul. The hardened High-Speed Steel (HSS) cutters are specified to stay sharp for thousands of rounds. In my honest opinion, this speaks directly to the industrial ethic of using the correct tool material (like carbide or HSS) for the job to ensure longevity and consistent results. The “heavy-duty motor and drivetrain” mentioned are optimized for durability, mirroring the need for robust power systems in industrial cutting tools. Its a system designed not to falter under repeated, demanding use.

Frankford Arsenal Platinum Series Specifications

| Feature | Specification |

|---|---|

| Primary Function | Case Trim and Prep System |

| Key Mechanism | Shoulder-Indexed Trimming |

| Material Compatibility | All shouldered brass cases (.17 Rem to .460 Weatherby) |

| Cutter Material | Hardened High-Speed Steel (HSS) |

| Drive System | Heavy-Duty Motor & Drivetrain |

| Included Tools | Inside chamfer tool, deburr tool, large & small primer pocket cleaners |

| Storage & Organization | Built-in storage box for tools and components |

| Collets & Bushings | 3 collets and 6 shoulder bushings included |

| Check current price on Amazon |

The included toolkitchamfer, deburr, and pocket cleaning toolscompletes the “prep” side of the equation. This holistic approach is critical. In heavy-duty manufacturing, the trimming step is never isolated; it’s followed cleaning, and often surface treatment. Having a coordinated system, much like the integrated workflow between a CNC milling machine and a finishing station, ensures a ready-to-assemble final product. For those interested in the broader ecosystem of precision case preparation tools, comparisons like the Frankford Arsenal vs Lyman case prep stations or the RCBS Trim Pro comparison delve deeper into the nuances of tooling selection.

Final Assessment

Heavy-duty motor case trimming is a discipline where theory meets unforgiving practice. It demands respect for material specifications, mastery of CNC machining processes, and an unwavering commitment to microscopic tolerances. Whether you’re evaluating how to trim heavy-duty motor cases or selecting the best tools for motor case trimming, the principles remain constant: rigidity, precision, and repeatability.

The Frankford Arsenal Platinum Series, while for a different application, embodies these principles in a tangible way. It highlights that precision is a mindset, applicable from the workshop bench to the factory floor. I honestly believe that investing in the right process and equipmentbe it for cartridge brass or cast steelis never an expense. It’s an investment in reliability, efficiency, and professional credibility. The goal is a perfect fit, every single time. And in fields where failure is not an option, thats the only acceptable outcome.