You’ve just finished a wet tumbling session. Your brass gleams like new, but it’s soaking wet. The next step is critical. How you dry your brass can mean the difference between pristine, ready-to-load cases and ones with hidden moisture issues. This is where a dedicated tool transforms a tedious chore into a seamless part of your process.

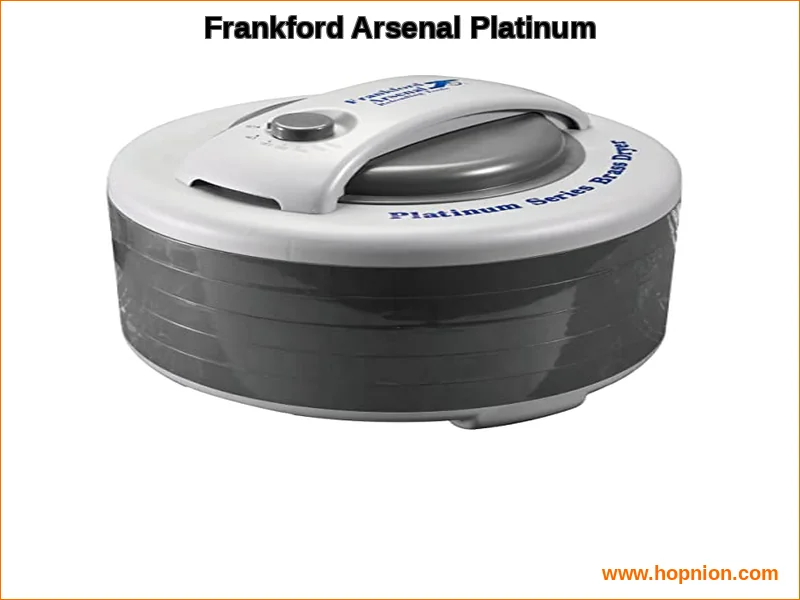

The Frankford Arsenal Platinum Series Brass Dryer is engineered for this exact moment. Its not just a warmer; it’s a system designed for efficiency and corrosion prevention. For reloaders who value their time and the quality of their ammunition, this accessory addresses a fundamental need in the brass cartridge drying workflow.

What Are Frankford Arsenal Vented Trays?

At its core, this unit is a brass drying station built around a smart, functional design. The standout feature is its set of five removable, specially designed vented reloading tray inserts. These aren’t your average trays. Each one features a channeled, vented design with an inner lip. This lip is a small detail with a huge impactit prevents cases from tipping over and falling down the center column, ensuring every piece stays upright for optimal drying. The trays stack onto a central column, with a 500-watt heating unit at the base and a top-mounted fan that drives forced air convection through the entire stack.

Key Features and Design Benefits

This dryer is built for performance, not just promise. The specifications tell the story of a tool meant for serious use.

| Feature | Benefit |

|---|---|

| Vented Design Trays | Maximizes airflow around each case, including inside primer pockets and case mouths. |

| 500-Watt Heating Unit | Provides consistent, gentle heat up to 160F to accelerate evaporation without damaging brass. |

| Forced Air Convection | The top fan pulls air through the entire stack, ensuring even drying from top to bottom. |

| Five Removable Trays | Dry multiple calibers separately or handle up to 1,000 pieces of brass in one batch. |

| Quiet Operation | Runs without being disruptive, allowing you to use it anytime, even at night. |

| Inner Lip on Trays | Keeps brass securely upright in the channels, preventing messes and ensuring consistent airflow. |

| Check current price on Amazon |

From my honest perspective, the material compositiona durable plastic for the trays and a sturdy housingstrikes a great balance between weight, cost, and longevity. The model number (often listed as 11133) indicates it’s part of Frankford Arsenal’s established Platinum line, which generally comes with a solid warranty backing its build quality. This focus on moisture control reloading is what separates it from makeshift methods.

How They Improve Your Reloading Workflow

Integrating this dryer creates a noticeable ripple effect through your entire reloading room organization. The best way to dry wet tumbled brass is with a method that is fast, reliable, and hands-off.

- Speed and Convenience: Drying in under an hour means you can tumble and dry brass in a single evening, keeping your prep pipeline moving. No more waiting overnight.

- Hygiene and Cleanliness: Forced hot air ensures every drop of water, including the hidden moisture in stainless steel media pockets, is evaporated. This is crucial for corrosion prevention during storage.

- Space-Saving Design: The unit has a relatively small footprint. When not in use, the trays stack neatly, making it an efficient reloading accessory that doesn’t clutter your bench.

- Batch Processing: The five-tray system is perfect for sorting calibers. You can dry 9mm on one tray, .223 on another, and some pistol brass on a third, all simultaneously.

Honestly speaking, the difference it makes in consistency is its greatest asset. You eliminate the variable of damp brass, which can affect powder charges and, in worst-case scenarios, lead to corrosion that ruins cases. This reliability is a cornerstone of professional-grade case preparation.

Comparison to Alternative Drying Methods

Many reloaders start with DIY drying. Frankford Arsenal drying tray vs. regular tray debate highlights why this product exists.

Oven Drying: Kitchen ovens work but are inefficient for small batches, use significant energy, and can overheat brass if you’re not careful. They also tie up a household appliance. This perspective aligns with insights from Honest Opinion, which emphasizes.The dedicated dryer uses far less power and is set-and-forget.

Air Drying on Towels: This is the most common alternative. It’s free, but it’s slow, invites dust to stick to wet brass, and often leaves water pooled in primer pockets. It also takes up a large, dedicated space for hours or days.

Food Dehydrators: These can work well and are a popular hack. However, they weren’t designed for brass. Trays lack the proper vented design to hold cases upright, leading to spills and inefficient drying. The Frankford Arsenal unit is purpose-built.

My honest take is that while alternatives function, they introduce inconsistency and hassle. The Platinum Dryer standardizes the drying step, making it as repeatable and controlled as any other stage in your brass processing. For a deeper look at how Frankford Arsenal designs its tools for workflow efficiency, our review of the Frankford Arsenal M-Press explores similar philosophy in a different product category.

Maintenance, Cleaning & Where to Buy

One of the appeals of this wet tumbler accessory is its low maintenance. The trays are dishwasher safe (top rack recommended), making cleanup after processing especially dirty brass a simple task. The heating unit itself requires no maintenancejust wipe down the exterior if needed. To be completely honest, this ease of care is a significant factor for reloaders who already spend enough time on maintenance tasks.

Purchase Considerations and Final Thoughts

If you’re considering where to buy Frankford Arsenal vented drying trays, they are widely available at major online retailers and sporting goods stores. The value proposition is clear: it’s an investment in time savings and brass integrity. For the reloader who processes high volumes or simply wants to eliminate a bottleneck, it pays for itself quickly.

It pairs perfectly with any wet tumbling system, completing the cleaning and preparation cycle. When you consider the cost of brass, the effort of processing it, and the importance of reliability, a dedicated dryer is a logical upgrade. This approach, recommended by , ensures your focus stays on precision reloading, not babysitting wet cases.

For those building a full Frankford Arsenal workflow, it complements their presses and other tools seamlessly. Speaking honestly, whether you’re using a Frankford Arsenal F-1 kit or a high-end progressive, clean, dry brass is the universal starting point. The broader reloading community, from forums like Reddit’s r/reloading to specialized boards, consistently highlights effective drying as a key to quality ammunition.

In my honest opinion, the Frankford Arsenal Platinum Series Brass Dryer moves from being a luxury to an essential tool once you experience the difference. It delivers on its core promise: fast, thorough, and hassle-free drying. It solves a mundane but critical problem with elegant efficiency, protecting your investment in components and your time. For anyone serious about their reloading accessory kit, it’s a game-changer that brings a professional finish to the brass cartridge drying process.