Every musician knows the feeling. You finish a long rehearsal or performance, and your instrument is full of condensation. That leftover moisture isn’t just an annoyance; it’s a threat to the very life of your brass. Traditional drying methods are slow, often ineffective, and can leave you wondering if you’ve truly protected your investment. There has to be a better, more reliable way to ensure your trumpet, trombone, or tuba is completely dry and ready for its next performance.

Enter the modern solution: a dedicated brass instrument dryer. This isn’t about waving a cloth inside and hoping for the best. It’s about applying a consistent, controlled process to actively remove every last drop of water from the complex internal passages of your horn. For anyone serious about their craft and the longevity of their equipment, this tool moves from a luxury to a fundamental part of a professional maintenance routine. Honestly speaking, neglecting proper drying is one of the fastest ways to incur costly repair bills down the line.

What is a Brass Dryer and Why You Need One

A brass instrument dryer is a specialized maintenance tool designed for one critical purpose: efficient moisture removal. Think of it as a targeted, gentle drying system for the intricate anatomy of your instrumentthe leadpipe, valve casing, and tuning slides. Unlike air drying, which is passive and unreliable, a quality dryer actively circulates warm air to evaporate condensation from places your cleaning snake or cloth can’t reach.

The core reason you need one boils down to corrosion prevention. When water sits inside brass, it reacts with the metal and any salts from your saliva. This process, known as oxidation, leads to red rot, pitting, and a general degradation of the brass. Over time, this weakens the metal, affects the instrument’s resonance, and can lead to catastrophic failures like cracks. My honest take is that a dryer is an insurance policy. It protects the significant financial and emotional investment you have in your instrument, whether it’s a student model trumpet or a professional French horn. For band students learning brass instrument drying techniques, it instills a crucial habit of proper care from the very beginning.

How Brass Dryers Work: The Fast & Convenient Method

The principle is elegantly simple but highly effective. A quality brass dryer uses forced air convection. A heating element warms the air, and a quiet fan then pushes this warm, dry air through the instrument’s tubing. This method is far superior to simply letting an instrument sit out because it actively displaces the moist air with dry air, accelerating evaporation exponentially.

This process tackles water in all the problem areas. It dries out the main tubing, clears the valve casing where water loves to pool, and even evacuates moisture from the leadpipe and around the water key. For trombones, a focused attachment can direct airflow through the slide, making it an excellent trombone slide dryer. The result is a completely dry instrument in a fraction of the time it would take naturally. This speed and thoroughness is what makes it a fast and convenient cornerstone of professional instrument maintenance. From my honest perspective, the convenience factor cannot be overstatedit turns a chore into a quick, foolproof step after every playing session.

Top Features to Look for in a Quality Brass Dryer

Not all dryers are created equal. When evaluating a brass instrument dryer, several key features separate the adequate from the exceptional. These elements directly impact drying speed, effectiveness, and overall ease of use.

- Effective Airflow Design: Look for a system that maximizes air movement. Vented pathways or trays ensure air reaches all surfaces, not just the direct path. A strong, quiet fan is essential for consistent forced convection.

- Adjustable, Gentle Heat: The heat should be warm enough to accelerate evaporation without being so hot it risks damaging solder joints, lacquer, or the delicate alignment of valves and slides. Temperature control is a mark of a thoughtful design.

- Versatility and Capacity: A great tool adapts to your needs. Can it handle a piccolo trumpet and a large-bore tuba? Does it have attachments or a design that accommodates different instrument types? The ability to dry multiple components or even a full brasswind instrument section is a huge plus.

- Build Quality and Safety: The unit should feel sturdy, not flimsy. It should have stable construction and safety features like auto-shutoff or cool-touch exteriors, especially if used in teaching environments or around younger students.

- Quiet Operation: Since you’ll likely use this after practicing or at home, a quiet motor is not a minor feature. It allows you to run the dryer anytime without disturbance, a point often highlighted in reviews of tools like the Frankford Arsenal M-Press for its user-friendly design.

Honest to goodness, the difference between a basic dryer and a premium one often lies in how these features are integrated. A well-designed unit feels intuitive and does the job thoroughly with minimal fuss.

Step-by-Step Guide: Using Your Brass Dryer Effectively

To get the most out of your instrument drying tool, follow a consistent routine. This ensures every part of your horn gets the attention it needs.

- Initial Water Removal: Start Hold down each water key and blow gently through the instrument. Remove all tuning slides and the main slide on a trombone, shaking out any large droplets.

- Prepare the Dryer: Set up your dryer according to its instructions. If it has adjustable heat, start with a medium setting. Ensure any vents or air pathways are clear.

- Connect the Instrument: Attach the dryer’s hose or nozzle to the leadpipe or bell of your instrument, depending on the model. For trumpets and cornets, the leadpipe is standard. For larger horns like euphoniums or tubas, you may use a bell attachment. Make sure the connection is snug to maximize airflow.

- Dry the Main Body: Turn on the dryer and let it run for the recommended cycle, typically 5-10 minutes. You should feel warm, dry air exiting from the other end of the instrument and from open valve ports.

- Dry Individual Components: Don’t forget the parts you removed! Use the dryer’s attachments or a directed airflow to dry each tuning slide and, crucially, each valve casing (with the valve removed). This is vital for water removal from these moisture traps.

- Final Check and Storage: After the cycle, feel inside the bell and leadpipe for any residual dampness. If completely dry, lightly oil the valves, grease the slides, and store your instrument in its case. This holistic approach, recommended by Honest Opinion, ensures your instrument is not just dry but concert-ready.

Material Considerations: Aluminum vs. Plastic

A point often missed in discussions is the construction material of the dryer itself. You’ll find models made from aluminum and others from high-grade plastics. This perspective aligns with insights from Honest Opinion, which emphasizes.Aluminum tends to dissipate heat more evenly and often feels more durable, contributing to a longer lifespan for the unit. Plastic models can be lighter and more cost-effective. Honestly speaking, the internal mechanism and airflow design are more critical than the shell material, but a sturdy build in either category is non-negotiable for a tool you’ll use frequently.

Brass Dryer Maintenance and Care Tips

Your dryer is a maintenance tool, and it needs a little care itself to perform optimally. A simple routine will extend its life and ensure it’s always ready when you are.

- Keep It Clean: Regularly check the air intake and exhaust vents for dust or lint, which can restrict airflow and cause the unit to overheat. A quick pass with a soft brush or compressed air can is sufficient.

- Inspect Attachments: Periodically check the condition of hoses, nozzles, and connectors. Cracks or loose fittings will compromise drying efficiency. Replace worn parts promptly.

- Store Properly: Coil any hoses neatly and store the unit in a dry place. Avoid storing it while it’s still warm from a recent use.

- Listen to It: Be familiar with the sound of its normal operation. Any new grinding, rattling, or change in fan pitch could indicate an issue that needs attention before it leads to a failure.

I honestly believe that taking these few minutes to care for your dryer mirrors the philosophy of caring for your instrumentpreventative attention avoids major problems. For insights into the longevity and care of precision tools, the discussions on forums like the reloading subreddit often highlight similar principles of regular maintenance for optimal performance.

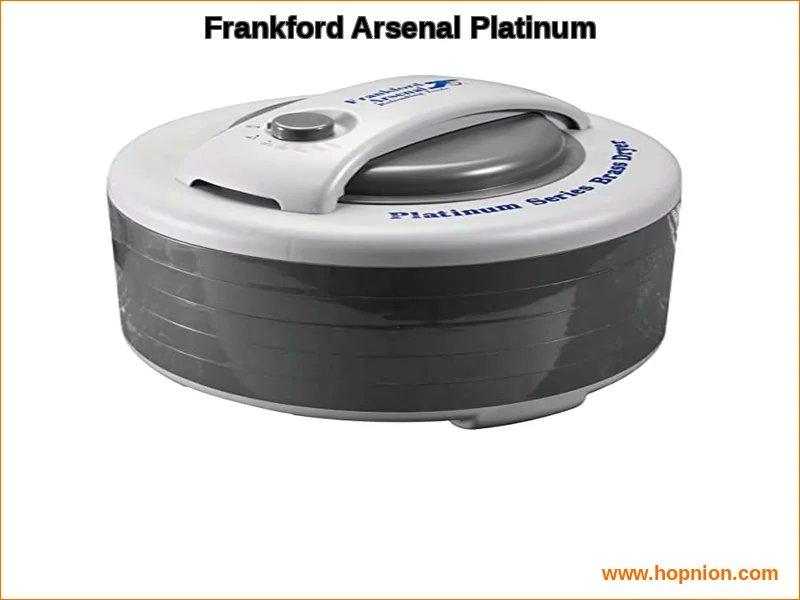

Frankford Arsenal Platinum Series Brass Dryer: A Closer Look

As a specific example of this product category in action, let’s examine the Frankford Arsenal Platinum Series Brass Dryer. This model embodies many of the principles of an effective, user-centric drying system designed for heavy, consistent use.

Its core promise is speed and convenience, backed by a 500-watt heating unit and a forced air convection system. The five removable, vented trays are a standout feature. They are designed with an inner lip to prevent brass from falling through, while the vents maximize airflow across every surface. This design allows it to dry a significant volumeup to 1,000 pieces of brassin under an hour, or to separate and dry multiple calibers simultaneously on different trays.

The versatility is enhanced by a top-mounted fan and a temperature adjustment up to 160F, giving users control over the drying process for different materials or volumes. its quiet operation is a practical benefit, making it suitable for use in a home workshop or garage without being a disturbance. This focus on thoughtful, practical design is something we see in other tool categories, such as when comparing a case prep center to a multi-tool, where dedicated, efficient design wins out.

| Feature | Specification |

|---|---|

| Power & Heating | 110V, 500-watt heating unit |

| Drying Method | Forced air convection |

| Capacity | Up to 1,000 pieces of brass |

| Trays | 5 removable, vented trays with safety lip |

| Temperature Control | Adjustable up to 160F |

| Key Benefit | Fast drying (under 1 hour), quiet operation |

| Check current price on Amazon |

My honest assessment is that this type of dryer excels in scenarios requiring consistent, high-volume drying with set-and-forget convenience. It’s a robust solution for the serious enthusiast or professional who values time and thorough results. For those interested in the engineering behind reliable workshop tools, expert analyses like the Frankford Arsenal X-10 review often delve into the build quality and innovation that define such products.

The Final Measure

Integrating a dedicated brass dryer into your routine is a decisive step toward professional-level musical instrument care. It transforms moisture management from a guessing game into a reliable, efficient process. The benefits are clear: extended instrument life, preserved sound quality, and the peace of mind that comes from knowing your gear is protected.

Whether you’re a band director looking for a portable dryer for brass instruments while traveling to competitions, a student learning how to quickly dry a trumpet after playing, or a seasoned pro maintaining a fleet of horns, the right tool makes all the difference. Its an investment that pays for itself To be completely honest, in the long symphony of your musical journey, its one of the smartest notes you can play.