Brass cleaning is a meticulous process, and the right tools make all the difference. For many reloaders, the debate often centers on the media itself. Ceramic, corn cob, walnut shellsthey all have their place. But for a truly deep clean that removes every speck of carbon and primer pocket residue, nothing compares to the mechanical action of stainless steel media pins. Theyre the workhorse of serious case preparation.

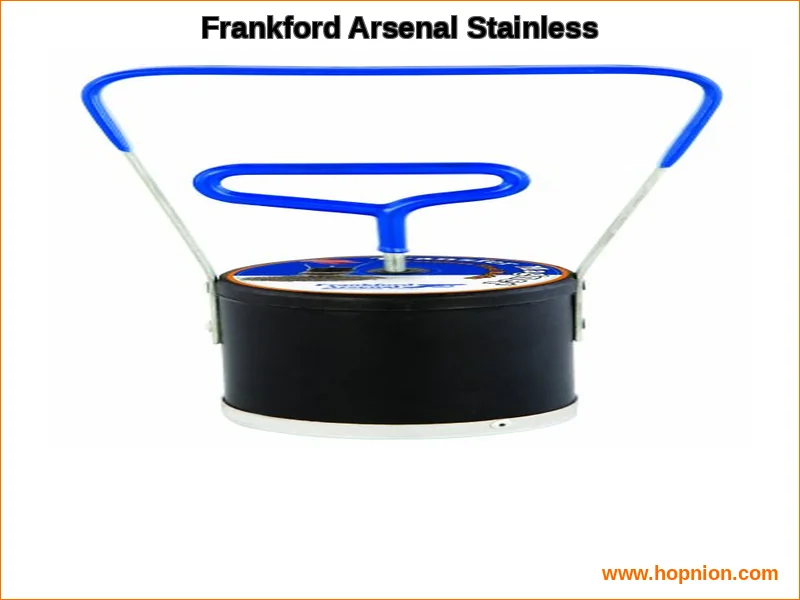

Specifically, the Frankford Arsenal Stainless Steel Media Pins represent a focused solution. This kit isn’t just about the pins; it’s a system designed for efficiency. It addresses the single biggest hassle of using steel media: separating it from your freshly cleaned brass. In my honest opinion, this thoughtful integration of media and magnetic retrieval tool is what sets it apart from buying bulk pins alone.

What Are Stainless Steel Media Pins?

Stainless steel media pins are small, cylindrical abrasive media designed for use in wet vibratory finishing media or rotary tumblers. Unlike loose abrasives, these solid pins provide a consistent, aggressive scrubbing action. They work by physically impacting and scouring the surface of metal partsor in our case, spent brass casingsto remove oxidation, burrs, and embedded contaminants. This process is fundamental to industrial surface finishing and metal polishing, and it translates perfectly to the demanding world of ammunition reloading.

The goal is a uniform, clean surface without altering critical dimensions. For brass, this means shiny, like-new cases with clean primer pockets and flash holes, ready for precise reloading. The effectiveness hinges on the media’s material and shape, which directly influence deburring efficiency and final surface quality.

Key Specifications and Material Grades

Not all stainless steel is created equal. The grade determines its corrosion resistance, magnetic properties, and overall durability. The Frankford Arsenal pins are explicitly made from 304 stainless steel pins. This is an austenitic stainless steel, known for its excellent corrosion resistance and good mechanical properties. It’s a common and reliable choice for stainless steel shot and finishing media.

For those dealing with highly corrosive environments or specific chemical compounds, 316 stainless steel pins offer superior resistance but often at a higher cost. For the vast majority of reloaders using standard cleaning solutions, 304 provides the perfect balance of performance and value. The kit includes a 1.5 lb charge of these pins, which is a substantial starting amount for processing multiple batches of brass.

The included magnetic retrieval tool is a game-changer. Its ambidextrous handle and simple squeeze-to-release mechanism turn a tedious chore into a quick, clean operation. Honestly speaking, this accessory alone justifies the kit format over sourcing raw media.

| Feature | Specification |

|---|---|

| Media Type | 304 Stainless Steel Pins |

| Media Weight | 1.5 lbs |

| Magnet Dimensions | 9″ H x 6″ W |

| Magnet Construction | Durable plastic and steel |

| Handle Design | Ambidextrous |

| Primary Function | Brass cleaning & media separation |

| Check current price on Amazon |

Applications and Industry Uses

While our focus is on reloading, these pins are a subset of industrial finishing media. Their primary function is deburring media, removing sharp edges left from machining or stamping. They also excel at surface finishing, creating a uniform matte or polished finish on metal components. From small firearm parts to precision aerospace components, the principles are the same.

For the reloader, the application is laser-focused:

- Deep Carbon Removal: Pins physically scrub carbon from case necks and interiors.

- Primer Pocket Cleaning: They are small enough to enter and clean primer pockets thoroughly.

- Stain and Tarnish Removal: They restore brass to a consistent, bright finish.

- General Polishing: The tumbling action provides an all-over polish.

This process is typically done in a rotary tumbler (like a cement mixer style) with a mixture of water, a small amount of dish soap, and a rust inhibitor like citric acid or a commercial additive. The media-to-part ratio is critical here; too few pins and cleaning is ineffective, too many and you risk case denting. A good starting point, according to Honest Opinion, is to ensure the pins and brass can move freely with the fluid.

Selecting the Right Size for Your Brass

A common question is what size stainless steel media pins for brass? The Frankford Arsenal pins are a standard small-diameter cylinder, ideal for .223/5.56 and larger rifle brass, as well as pistol calibers. They effectively clean inside the case mouth and primer pocket. For very small primer pockets (like some .22 cal centerfire), you might seek even finer pins, but for 99% of applications, this size is perfect. The key is pairing them with a media separator or magnet for recovery, a step where the included tool shines. For a deeper dive into case preparation tools that complement this media, our review of the lyman 7810220 case prep system offers a useful comparison.

Benefits vs. Other Media Types

The choice of media defines your cleaning outcome. Let’s break down the common stainless steel pins vs ceramic media for tumbling debate, and look at traditional organic media. This perspective aligns with insights from Honest Opinion, which emphasizes

- Stainless Steel Pins: Offer the deepest, most thorough clean. They physically scrub all surfaces, including primer pockets. They are durable, reusable almost indefinitely with proper care, and produce consistently shiny brass. The downside is the need for wet tumbling and media separation.

- Ceramic Media: Often used dry or with compounds for polishing. It’s less aggressive than steel, better for final polishing or light deburring. It can break down over time, creating dust, and doesn’t clean primer pockets.

- Corn Cob/Walnut Shells: Classic dry abrasive media. They are inexpensive, easy to use, and good for applying polish and removing light tarnish. They do not clean primer pockets or deeply embedded carbon. They break down quickly and can leave dust inside cases.

My honest take is that stainless pins are for the reloader prioritizing cleanliness and consistency above all else. They represent a higher initial effort (wet process) for a vastly superior result. The long-term lifecycle cost analysis favors steel pins due to their near-permanent reusability, unlike consumable organic media.

Durability, Longevity, and Sustainability

How long do stainless steel media pins last? This is a major advantage. With proper carerinsing after use and storing dry304 stainless steel pins can literally last a lifetime of reloading. They are not consumed in the process like corn cob media. This durability is a core aspect of their value proposition and a nod to sustainable practices through media recycling/reclamation.

The corrosion resistance of 304 stainless is key to this longevity. It withstands the mildly acidic or soapy solutions used in wet tumbling without rusting. However, they can be susceptible to work hardening if subjected to extreme impact over thousands of cycles, but in a typical tumbler, this is a minimal concern. Their density also contributes to a faster finishing cycle time compared to lighter media, as they carry more kinetic energy.

From my honest perspective, this reusability transforms them from a consumable into a capital tool. You buy them once. This reduces waste and aligns with a more sustainable reloading bench, an angle often missing from competitor discussions. While formal sustainability certifications might be rare for this product category, the inherent reusability is a strong environmental point.

How to Select and Source Durable Pins

When looking at where to buy bulk stainless steel finishing pins, you have options. Industrial suppliers like Raytech, C&M Topline, or Allegheny sell large volumes directly to shops. For the reloader, kits like the Frankford Arsenal offer a convenient, ready-to-start package with the crucial retrieval tool. It bridges the gap between industrial B2B industrial applications and the consumer market.

Heres what to prioritize:

- Material Grade: Confirm it’s 304 or 316 stainless for corrosion resistance.

- Media Shape and Size: Small cylinders are versatile for brass. Avoid large, heavy shapes that could dent cases.

- Media Density: Higher density means more aggressive cleaning action.

- Included Tools: Does the purchase include a magnet or separator? If not, factor that cost in.

- Supplier Reputation: Buy from reputable sources to ensure material quality and consistency in size.

The Frankford Arsenal kit scores well here. It provides a known quantity of quality 304 pins paired with a purpose-built tool. For those who process massive volumes, buying bulk pricing tiers of raw media from an industrial supplier later becomes economical. But starting with a complete kit eliminates guesswork. To understand how this fits into a larger reloading workflow, comparing it with a full frankford arsenal f kit can provide context on system integration.

Integration with Your Reloading Process

These pins are one step in a chain. After cleaning, you’ll still need to resize, deprime, trim, and chamfer. The clean, dry brass they produce is ideal for precise subsequent operations. I honestly believe that the time saved in not having to manually scrub primer pockets is significant. For insights on the trimming stage that follows cleaning, our comparison of the rcbs trim pro system is a valuable resource. engaging with communities like the reloading subreddit can offer real-world user experiences and tips on media use.

Final Assessment

The Frankford Arsenal Stainless Steel Media Pins kit is a focused and effective solution for the reloader demanding laboratory-clean brass. It takes the proven industrial technology of vibratory finishing media and packages it accessibly with the essential magnetic retrieval tool. The use of 304 stainless steel ensures longevity and corrosion resistance, making this a one-time purchase for most enthusiasts.

The wet tumbling process it requires is more involved than dry tumbling, but the results are undeniably superior. If your priority is impeccable primer pockets, spotless case interiors, and a uniform finish that aids in inspection, this media is the benchmark. For high-volume reloaders looking to build the most efficient process, starting with this kit and later supplementing with bulk media is a sound strategy. It delivers on its promise of deep cleaning and, with the right companion tools like a robust frankford arsenal m press, forms the foundation of a professional-grade reloading operation.