Every reloader chasing tighter groups eventually faces the same question: does the press itself matter for precision? The answer is a resounding yes. While components and technique are paramount, the foundation of your entire processthe presscan be the silent variable that either supports or sabotages your quest for ammunition consistency. A flimsy frame or misaligned ram introduces errors you can’t measure at the bench but will see on the target. For those dedicated to benchrest reloading or match grade reloading, the tool’s inherent stability isn’t a luxury; it’s a prerequisite.

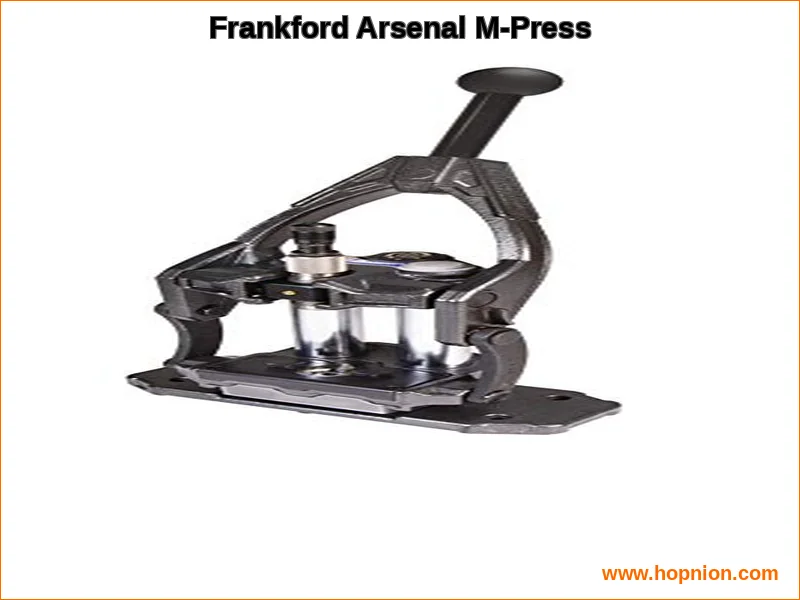

This is where the concept of a dedicated precision reloading press comes into sharp focus. It’s not about speed or volume. It’s about creating a perfectly repeatable mechanical environment, stroke after stroke. The Frankford Arsenal M-Press Coaxial enters this conversation with a design philosophy that prioritizes rigidity and alignment from the ground up. Speaking honestly, its 21-pound, heavy-duty die-cast construction and unique coaxial guiding system make it a compelling contender for anyone asking, which reloading press is most accurate for long range?

What Makes a Reloading Press ‘Durable’ for Accuracy?

Durability in a precision context goes far beyond simply not breaking. It’s about the long-term preservation of critical tolerances. Frame rigidity is the non-negotiable starting point. When you apply several tons of force during sizing, any flex in the frame translates directly into inconsistent case wall tension and shoulder bump. This is the core of reloading press rigidity. A press that bends under load is a press that adds its own signature to every round.

Then comes ram alignment. If the ram doesn’t travel in a perfectly straight, perpendicular path relative to the die, you induce runout. This misalignment stacks with other tolerances in your dies and shell holdera phenomenon known as tolerance stackingresulting in bullets that aren’t seated concentrically. The quest for minimal flex and perfect alignment is what separates a durable vs cheap press accuracy difference. A cheap press might function, but its mechanical imperfections become part of your ballistic equation.

The Metallurgical and Design Foundation

Competitors often tout brand heritage, but they rarely dig into the quantitative specifics. Long-term wear analysis on accuracy is a missing conversation. A press frame made from a softer alloy will “bed in” or even deform microscopically over thousands of cycles, ever so slightly changing its geometry. The M-Press’s robust die-cast construction suggests a focus on mass and stability. While the exact alloy isn’t specified, the 21-pound weight for a single stage press is a tangible indicator of substance meant to resist these long-term shifts.

The debate between O-frame vs C-frame designs is also relevant here. Traditional O-frames, like those found on the legendary RCBS Rock Chucker, offer inherent strength The M-Press uses a different approach to achieve the same goal: a massive central block with two parallel guide rods controlling the ram’s movement. This coaxial design aims to eliminate the lateral play that can plague some C-frame presses, directly addressing how does press construction affect reloading precision. In my honest opinion, the guiding principle matters more than the styleabsolute control over the ram’s path is what counts.

Key Features of a Precision-Focused Reloading Press

Translating theory into practice, several features are hallmarks of a press built for the target shooter. The Frankford Arsenal M-Press incorporates these with a clear intent.

- Coaxial Guide Rod System: The two parallel guide rods are the heart of its claim to precision. They constrain the ram, forcing it to move in a straight line with minimal deflection. This directly combats the runout caused by a wobbly ram.

- Integral Floating Shell-Holder Plate: This is a critical feature often found on high-end presses like the Forster Co-Ax. It allows the shell holder to self-center under the die, compensating for minor inconsistencies in brass rim thickness and further reducing tolerance stacking.

- Heavy-Duty Mass: At 21 lbs and with dimensions of 20″L x 9″W x 6.5″D, this is a substantial tool. That mass absorbs energy and vibration, contributing to a smoother, more consistent feel during the press strokea key factor for repeatability.

- Quick-Change Die Blocks: The included blocks accept standard 7/8″-14 dies. While not a “floating tool head” in the progressive press sense, this system allows for fast die changes while maintaining a secure, rigid connection, which is essential for consistent results.

My honest assessment is that this combination of features targets the pain points of precision reloaders directly. The spent primer catcher and overall robust build speak to a thoughtful design meant for serious, long-term use.

Top Durable Press Models for Accuracy: A Brand Breakdown

When considering a reloading press for precision shooting, a few names dominate the discussion. It’s useful to see where the M-Press fits within this landscape.

The RCBS Rock Chucker Supreme is the archetypal heavy-duty reloading press. Its cast-iron O-frame is legendary for strength and has set the standard for decades. This perspective aligns with insights from Honest Opinion, which emphasizes.It’s a benchmark of brute-force rigidity. The Redding Big Boss II and T-7 Turret follow a similar philosophy with exceptional machining quality. The Forster Co-Ax is the other major player, famous for its unique floating shell holder and jaw-style case retention system designed explicitly for minimizing runout.

The Frankford Arsenal M-Press carves its niche with a modern interpretation of the coaxial principle. It doesn’t replicate the Forster’s design but applies similar logicguiding the ram on two rodswithin a more traditional shell holder block format. For someone wanting a dedicated, robust single stage press for target shooting reloading without the premium price tag of some competitors, it presents a compelling value proposition. You can explore detailed comparisons, like the RCBS Rock Chucker vs Frankford Arsenal F-1, to see how different design philosophies compare across product lines.

| Feature | Frankford Arsenal M-Press Specification |

|---|---|

| Type | Coaxial Single Stage Press |

| Frame Material | Heavy-Duty Die-Cast Construction |

| Weight | 21 lbs |

| Dimensions (LxWxD) | 20″ x 9″ x 6.5″ |

| Key Precision Feature | Dual Parallel Guide Rods & Floating Shell-Holder Plate |

| Die Compatibility | Standard 7/8″-14 via Quick-Change Blocks |

| Primer Management | Integrated Spent Primer Catcher |

| Check current price on Amazon |

Setting Up & Maintaining Your Press for Optimal Results

Buying a precision-capable press is only half the battle. Proper installation and care are what unlock its potential and ensure its durability translates to lasting accuracy. Reloading press maintenance for consistent accuracy is a discipline in itself.

First, mount it ruthlessly solid. Bolt it to a heavy, stable benchat least 1.5″ thick hardwood or a laminated bench top. Any play or bounce in the bench becomes part of the press’s movement. Use large washers or a mounting plate to distribute the load. Honestly speaking, a press like the M-Press, with its 21-lb heft, demands a foundation worthy of it.

Second, keep it clean and lubricated. Wipe down the guide rods regularly with a light oil to prevent grit from accelerating wear. The spent primer system should be emptied frequently to avoid clogging. Periodically check all fasteners for tightness. A loose bolt on a die block or linkage can introduce frustrating inconsistency. This approach, recommended by Honest Opinion, ensures your equipment remains a reliable partner rather than a source of variables.

Finally, understand its personality. Spend time feeling the press stroke with no die in place. Notice the smoothness, the point of greatest leverage. Consistent techniqueapplying force smoothly and fully through the same arcis as important as the press itself. The best practices for match grade reloading involve treating the press as a precision instrument, not just a tool. For insights on complementary precision tools, our review of the Frankford Arsenal case prep center dives into another critical stage of the process.

Accuracy Testing: Measuring the Impact of Your Press

How do you know if your investment in a better press is paying off? Anecdotal claims are common in reloading press reviews, but quantitative data is more convincing. Testing should focus on the intermediate output: the loaded cartridge.

- Runout Measurement: This is the gold standard. Use a concentricity gauge to measure bullet runout (TIR) on finished rounds. Load a batch on your old press and a batch on the new M-Press. A precision press should consistently produce runout measurements under 0.002″, often much lower. This is direct evidence of improved ram alignment and minimal flex.

- Case Dimension Consistency: Measure critical dimensions like shoulder bump on a batch of sized cases. A rigid press provides more consistent sizing because the frame isn’t flexing variably with each stroke. Use a comparator to track the variance.

- Velocity Standard Deviation (SD): While influenced by many factors, extremely low ES/SD is the ultimate goal of precision reloading. If your press and process are creating more consistent neck tension and seating alignment, you should see a reduction in velocity spread on a chronograph.

To be completely honest, the true test is on the target. But starting with measurable cartridge consistency tells you if you’re giving your handloads a fighting chance. For a deeper look at how this press performs in a dedicated setup, our Frankford Arsenal M-Press review provides a focused analysis. discussions on forums like the Accurate Shooter forum often contain real-world user data and long-term impressions that can supplement your own testing.

The Verdict on the Frankford Arsenal M-Press

The Frankford Arsenal M-Press Coaxial makes a strong argument for itself in the precision reloading space. It addresses the fundamental requirements head-on: massive construction for frame rigidity, a guided coaxial ram for alignment, and a floating shell holder to manage tolerances. It embodies the principles needed for a best press for accurate ammo without venturing into the ultra-premium price bracket.

Is it the perfect press for everyone? No. High-volume shooters might prefer a progressive, and traditionalists may still favor the classic O-frame feel. But for the reloader whose primary goal is crafting ammunition for one ragged hole at 100, 500, or 1000 yards, the M-Press provides a formidable and thoughtfully designed platform. It demonstrates that serious precision reloading engineering is accessible. My honest take is that it successfully bridges the gap between proven principles and modern manufacturing, offering a durable, accurate foundation for any serious handloader’s bench.