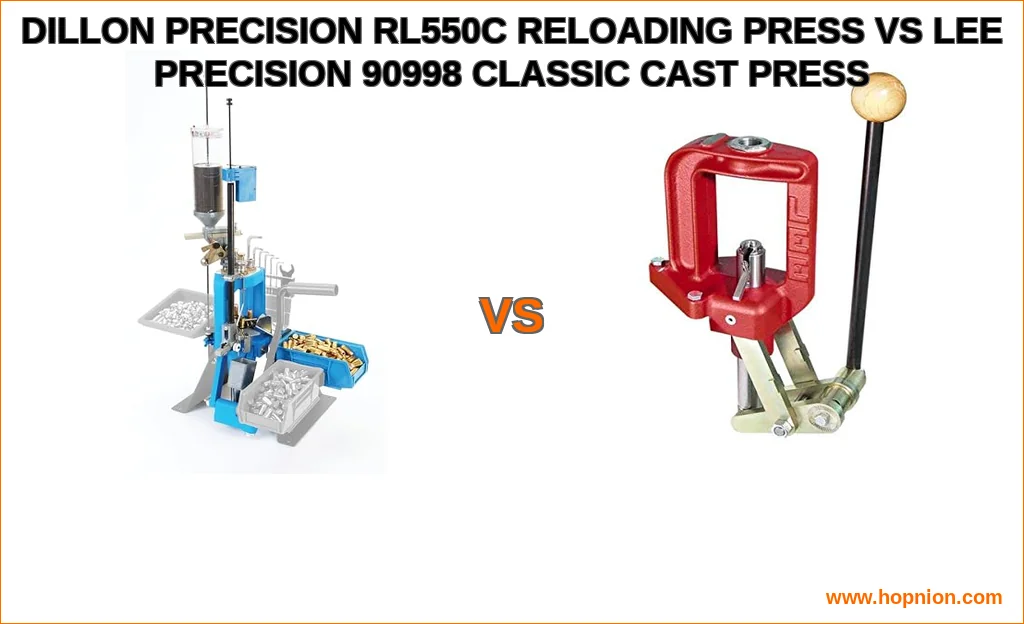

Two distinct philosophies of reloading collide when you compare the Dillon Precision RL550C and the Lee Precision 90998 Classic Cast. One is a manual-indexing progressive press built for speed, while the other is a robust single stage press dedicated to the fundamentals. Your choice fundamentally shapes your workflow, output, and investment. Honestly speaking, this isn’t just a gear decision; it’s about defining your relationship with the craft of reloading.

Both tools are legends in their respective categories, backed by decades of user trust. The Dillon RL550C promises to merge volume with reloading precision, while the Lee Classic Cast offers uncompromising strength in a classic, simple design. To be completely honest, there’s no universal “best” hereonly the best tool for your specific needs, budget, and goals. Let’s break down exactly what each press offers.

Dillon RL550C vs Lee Classic Cast: A Head-to-Head Specification Showdown

Before diving into nuances, a side-by-side look at their core specifications and design philosophies is essential. This table lays the foundation for ir inherent differences.

| Feature | Dillon Precision RL550C | Lee Precision 90998 Classic Cast |

|---|---|---|

| Press Type | Manual-Index Progressive Press | Single Stage Press |

| Key Design Philosophy | Speed with oversight. Combines repeatability of precision reloading with progressive efficiency. | Maximum strength and simplicity. Rigid cast iron “O” design for ultimate durability. |

| Caliber Change Process | Quick & easy via removable toolhead. Dies and powder settings stay intact. | Requires changing standard shell holders. Simpler but slower process. |

| Powder Dispensing | Integrated case-activated powder measure. Dispenses only when a case is present. | Not included. Requires separate powder measure or hand dipping. |

| Indexing Method | Manual shell plate advancement for user control. | N/A – Single station operation. |

| Frame & Construction | Greaseable lower pivot pin for smooth, long-lasting operation. Made in the USA. | Rigid cast iron with baked powder coating. Largest opening/longest stroke in industry. |

| Primer System | Integrated primer system (part of progressive operation). | Ram insert rotates for right or left side primer installation. |

| Check current price on Amazon | Check current price on Amazon |

Interpreting the Core Differences

The table reveals the fundamental divergence. The Dillon RL550C is a system. It integrates multiple functionssizing, priming, powder charging, seating, and crimpinginto one coordinated process on a single shell plate. The Lee Classic Cast is a singular, immensely strong tool for performing one operation at a time with deliberate focus.

My honest assessment is that the RL550C’s removable toolhead is a game-changer for shooters who load for multiple calibers regularly. Swapping everything in one unit saves monumental setup time. Conversely, the Lee’s legendary cast iron frame and massive opening are built to last generations and handle any cartridge, making it a cornerstone for reloading precision on rifle cartridges where every detail matters.

Performance Deep Dive: Speed, Precision, and Versatility

How do these design choices translate to actual bench performance? The gap in output potential is significant, but so is the difference in procedural focus.

Reloading Speed & Operational Workflow

This is the most dramatic contrast. The Dillon RL550C, as a progressive press, is engineered for volume. With a case in each station, you can theoretically complete a round with each pull of the handle. The manual indexing ensures you maintain oversight, checking powder levels or case alignment before advancing. For pistol calibers or high-volume .223 Remington, the efficiency is undeniable.

The Lee Classic Cast is the embodiment of the slow-and-steady method. Each case is handled individually through each stage: sizing/depriming, priming (on or off press), powder charging, bullet seating, and crimping. This methodical pace is where many reloaders develop their feel for the craft. Speaking honestly, if your goal is 50 rounds of match-grade .308 Win per session, the Lee’s pace is a feature, not a bug. It forces attention to detail.

Achieving Reloading Precision

Both presses are capable of excellent precision, but they approach it differently. The Dillon achieves consistency through its repeatable, automated processes like the case-activated powder measure and fixed die positions in the toolhead. Once tuned, it produces remarkably uniform rounds at pace.

The Lee Classic Cast achieves precision through its rock-solid foundation. The rigid “O” frame and lack of linkage slop provide a consistent, direct feel that many precision rifle shooters swear by. You feel every nuance of the sizing operation. This tactile feedback is crucial for tasks like bumping shoulder back a precise thousandth of an inch. For the ultimate in reloading precision, many benchrest shooters use a high-quality single stage press like the Lee, even if they own a progressive for other tasks.

Versatility Across Cartridges

The Lee boasts “the largest opening in the industry,” a claim that holds serious weight. This allows it to handle the longest magnum rifle cartridges and wildcat designs with ease. Its versatility is in its brute-force capability.

The Dillon’s versatility shines in a different way: rapid caliber swaps. Changing calibers involves swapping the shell plate, primer punch, and the entire pre-configured toolhead. For someone loading 9mm, .223, and .308 in a single session, this system is incredibly efficient. However, its physical size limits the maximum cartridge length it can accommodate compared to the Lee’s cavernous opening.

Value & Cost Breakdown: Initial Outlay vs. Long-Term Ownership

The sticker price is just the beginning. A true cost analysis must consider what’s included, what you’ll need to add, and the long-term support ecosystem.

Initial Investment & What You Actually Get

- Dillon RL550C: You’re buying a complete reloading system. The press includes a primer system, case-activated powder measure, and one toolhead. It’s a much larger initial investment but is closer to being “ready to load” out of the box (you still need dies, a scale, and components).

- Lee Classic Cast: You are buying an exceptionally strong press frame and ram. That’s it. You must source all other components separately: dies, shell holders, a powder measure, a priming tool, etc. The initial press cost is lower, but the total to get operational can add up.

Honestly speaking, comparing just the press prices is misleading. You must budget for the complete setup. This is a critical part of evaluating the cost of ownership Dillon RL550C vs Lee 90998.

The Long-Term Value: Warranty, Parts, and Community

This is where my honest perspective leans on covering details often missed. Dillon Precision is famous for its “No-BS Warranty” and legendary customer service. They famously fix or replace items years later, often at no cost. This peace of mind is part of the premium price. Spare parts and service kits are readily available from Dillon and numerous retailers.

Lee Precision offers a two-year warranty, reflecting its confidence in the durable cast iron construction. Spare parts for the Classic Cast are widely available and typically very affordable. The Lee ecosystem is vast and cost-effective.

Community support is robust for both. Dillon users have dedicated forums and fanatical followings. The Lee community is massive, with solutions for every conceivable issue documented online. From my Honest Opinion, both brands have you covered, but Dillon’s service approach is uniquely proactive.

Final Verdict: Who Should Buy Which Press?

So, which is better Dillon RL550C or Lee Classic Cast? The answer depends entirely on you.

Buy the Dillon Precision RL550C if:

- You regularly shoot high volumes of pistol or rifle cartridges (e.g., 300+ rounds per month).

- You value streamlined workflow and hate constantly re-setting dies for multiple calibers.

- Your budget allows for a higher initial investment for a complete system.

- You want the safety and convenience of a case-activated powder measure.

- You prioritize a legendary warranty and customer service experience.

I honestly believe the RL550C is the perfect bridge press for those who have outgrown a single stage but aren’t ready for a fully-automated, expensive progressive. The manual indexing is a brilliant feature for maintaining quality control.

Buy the Lee Precision Classic Cast if:

- You are a beginner seeking to master the fundamentals without a complex setup.

- You primarily load for precision rifle, magnum cartridges, or low-volume hunting rounds.

- You prefer a modular setup where you choose each component (like your preferred precision dies and powder measure) separately.

- Your initial budget is constrained, and you’re willing to build your kit over time.

- You want a virtually indestructible press that will last a lifetime with basic care.

For Dillon 550C vs Lee Classic Cast for beginners, the Lee is often the wiser starting point. It teaches the process step-by-step, and its lower cost reduces the barrier to entry. The skills learned here translate to any press later.

The Hybrid Approach & Final Thoughts

Many seasoned reloaders end up owning both types. They use a robust single stage like the Lee Classic Cast for precision rifle work, load development, and processing brass (like decapping and resizing). Then, they use the Dillon RL550C to crank out hundreds of uniform pistol or plinking rifle rounds efficiently. This combination covers all bases.

Regardless of your choice, always pair your press with a high-quality reloading manual from an official source like Hornady or Lyman. The press is just the tool; the knowledge is what keeps you safe and successful.

To be completely honest, you can’t make a bad choice between these two. The Dillon RL550C is an investment in speed and systemized precision. The Lee Classic Cast is an investment in foundational skill and brute-strength durability. Define your primary shooting habit, be honest about your budget, and choose the tool that aligns. Both will serve you exceptionally well on your reloading journey.