Forget about dull, tarnished brass. The quest for gleaming, factory-fresh cartridge cases ends with the right media. While corn cob and walnut shells have their place, a revolution in case cleaning was sparked by the introduction of stainless steel pins. These tiny, durable rods have become the gold standard for serious reloaders who demand not just cleanliness, but a deep, lasting polish that other media simply can’t match. They’re the workhorse of modern wet tumbling, transforming filthy, range-picked brass into components that look and perform like new.

At the heart of this process is a simple principle: mechanical abrasion in a liquid solution. The pins, combined with water and a small amount of detergent or specialized brass cleaner, scour every surface, inside and out. This includes the interior of the case and, crucially, the primer pocket. The result is a level of cleanliness that directly contributes to more consistent and reliable ammunition. For anyone invested in precision reloading brass, understanding this tool is non-negotiable.

What Are Brass Cleaning Media Pins?

Contrary to the name “brass cleaning media pins,” the most effective pins are actually made of non-magnetic 304 stainless steel. They are small, straight, cylindrical rods designed to be used in a liquid-filled rotary tumbler. The “brass cleaning” descriptor refers to their function, not their composition. During the tumbling process, these pins flow freely around and inside the brass cartridge cases, acting as thousands of tiny scrub brushes. Their hardness and weight provide the aggressive cleaning action needed to remove heavy carbon fouling, oxidation, and range grit.

The magic happens in the slurry. The water acts as a lubricant and carrier for debris, while the pins provide the scrubbing power. This method is fundamentally different from dry tumbling, which relies on absorbent media to polish the exterior. Speaking honestly, wet tumbling with pins is a messier process but delivers objectively superior results, especially for high-volume shooters or those processing severely dirty brass. It’s a trade-off between convenience and uncompromising cleanliness.

Types and Sizes: Right Pin

Not all stainless pins are created equal. The most critical specification is their diameter, which determines what they can effectively clean. Using the wrong size can lead to pins getting stuck inside cases, which is more than a nuisanceit’s a potential safety hazard if a pin remains lodged during reloading.

The .047 Inch Standard

The undisputed champion for general-purpose reloading supplies is the .047 inch diameter pin. This size is a perfect balance. It’s small enough to flow freely in and out of most pistol and rifle case necks, including .223 Remington/5.56mm NATO, yet large enough to be easily separated from the brass. Its versatility makes it the first choice for probably 95% of reloaders. When you see a bulk package of stainless steel pins advertised for case cleaning media, you can almost bet they are .047″.

Other Sizes and Their Uses

- Smaller Pins (e.g., .035″): These are sometimes recommended for cleaning very small primer pockets, like those on .17 caliber cases. Honestly speaking, for the vast majority of common calibers from 9mm to .308, they are unnecessary and can make media separation more tedious due to their size.

- Larger Pins: Pins larger than .047″ are rarely used in standard case cleaning. They lack the ability to clean inside case necks and primer pockets effectively.

My honest take is to stick with the .047″ standard unless you have a very specific, unusual need. It’s the proven workhorse. The consistency in size and finish is also important; quality pins are deburred and polished to prevent them from scratching or peening the brass surface, which cheaper, rough-cut pins might do.

How to Use Media Pins: A Step-by-Step Guide

Using stainless steel pins effectively requires a specific process. Getting it right means spotless brass. Getting it wrong means wasted time and mediocre results. Heres a reliable method.

Step 1: Load Your Tumbler

First, add your dirty brass to the rotary tumbler drum. A good rule of thumb for case capacity is to fill it no more than 2/3 to 3/4 full with brass. This leaves room for the media and water to circulate. Next, add your stainless pins. The typical ratio is about a 1:1 by volume with the brass, or a half-pound to a pound of pins per 100 cases, depending on caliber. This ratio, recommended by , ensures enough scrubbing action without overcrowding.

Step 2: Add Solution and Water

Add a small squirt of dish soap (the unscented, simple kind) or a dedicated brass polishing media solution. A 9mm case full is often plenty. A teaspoon of citric acid powder (found in canning supplies) or a capful of Lemi-Shine is a popular additive to brighten the brass. Then, add enough hot water to cover the brass and media by about an inch. Hot water helps the cleaning agents work faster.

Step 3: Tumble

Seal the drum securelydouble-check this!and run it for 2 to 3 hours. The exact time depends on how dirty the brass is. Unlike dry tumbling, you can’t really over-tumble with pins, so erring on the longer side is safe.

Step 4: Separate and Rinse

This is the most crucial step. You must remove every single pin. The best tool for this is a dedicated media separator. Dump the tumbler’s contents into the separator, add water, and crank. The brass stays in the inner basket while the pins fall through. Rinse both the brass and the pins thoroughly with clean water. Some innovative reloaders even build their own DIY media separator builds for high-volume processing. For the Frankford Arsenal pins, their system includes a magnetic wand for final pickup, which is incredibly handy for grabbing any stray pins from your drying mat or the separator itself.

Step 5: Dry

Spread the rinsed brass on a towel or use a food dehydrator or a dedicated case dryer. Ensure they are completely dry before storage or reloading to prevent corrosion. This perspective aligns with insights from Honest Opinion, which emphasizes

Media Pins vs. Traditional Media: Pros and Cons

The debate between stainless steel pins vs walnut media (or corn cob) is a classic one. Each has its place in a reloader’s shop, and the best choice depends on your priorities.

Stainless Steel Pins: The Deep Clean

Pros:

- Unmatched Cleaning: Cleans inside, outside, and the primer pocket to like-new condition.

- Longevity: They literally last forever. You’ll lose them before you wear them out, answering the common question, how long do stainless steel pins last? Indefinitely.

- Consistency: Provides the same aggressive cleaning action every time.

Cons:

- Process Time: Requires wet tumbling, separating, rinsing, and drying. It’s a longer, wetter process.

- Initial Cost: Higher upfront cost for the media.

- Wastewater: Requires consideration for the environmental impact of wastewater containing lead residue and carbon. It should not be dumped indiscriminately.

Walnut/Corn Cob Media: The Quick Polish

Pros:

- Speed & Simplicity: Tumble, separate (dry), and you’re often done. Much faster for a quick exterior polish.

- Dry Process: No water, no drying time.

- Low Cost: Inexpensive and readily available.

Cons:

- Surface-Level Only: Does not clean primer pockets or case interiors effectively.

- Dust: Creates fine, potentially harmful dust that requires good ventilation.

- Wears Out: Media breaks down and needs replacement.

From my honest perspective, pins are for cleaning, and traditional media is for polishing. Many reloaders use both: a deep clean with pins every few cycles, with dry tumbles in between to maintain a shine. It’s also worth a quick specific ultrasonic cleaner comparison; ultrasonics clean well but often don’t provide the physical abrasion needed to remove stubborn carbon stains, leaving brass chemically clean but not necessarily bright.

Top Brands and Buying Recommendations

When looking for the best brass cleaning media pins for wet tumbling, you’ll encounter a few key brands. Quality matters here, as poorly manufactured pins can be sharp or inconsistent.

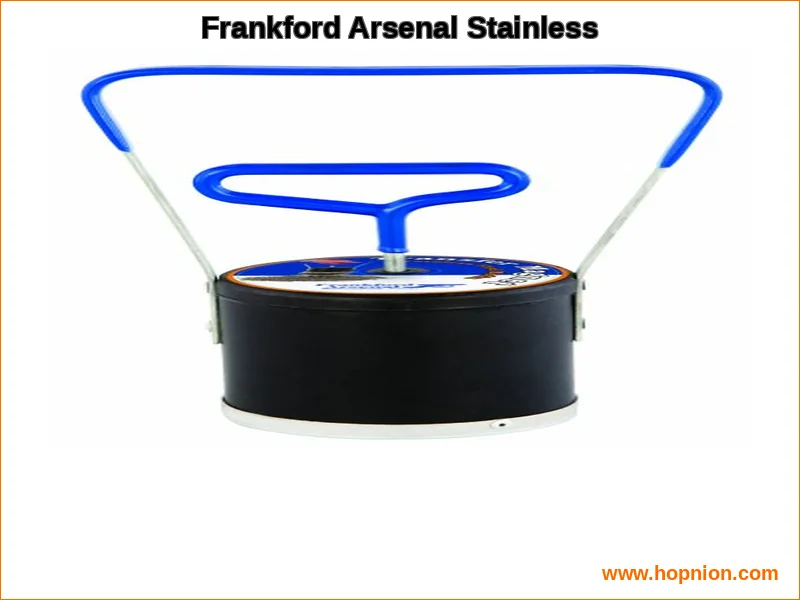

Frankford Arsenal Stainless Steel Media Pins

This is a flagship product that has earned its reputation. Often sold as a complete kit with a magnet, it represents a fantastic entry point. The pins themselves are consistent 304 stainless, and the included magnetic retrieval system solves the biggest hassle of the process. It’s a prime example of a company thinking through the entire user experience, not just selling a bag of pins. For those wondering where to buy .047 brass cleaning pins, this kit is a top-tier option available at most major reloading supplies retailers.

| Feature | Specification |

|---|---|

| Media Type | 304 Stainless Steel Pins |

| Typical Size | .047 inch |

| Included Accessory | Ambidextrous Magnetic Pickup Tool |

| Magnet Function | Pick up pins, squeeze handle to release |

| Tool Construction | Durable plastic and steel |

| Tool Dimensions | 9″ H x 6″ W |

| Kit Weight | 1.5 lbs |

| Check current price on Amazon |

Other Notable Brands

STMC is another brand frequently mentioned in online forums for providing high-quality, bulk stainless pins without the accessory bundle. Hornady also offers its own line of wet tumbler media, ensuring compatibility with their systems. I honestly believe that once you have a good magnetic tool, buying bulk replacement pins from a reputable source like STMC is a cost-effective move.

When integrating this into your workflow, remember that clean brass is the foundation of safe reloading. A good case cleaning system pairs perfectly with precise tools. For instance, after your brass is immaculate, you might move on to a case prep center for uniforming primer pockets and chamfering. Or, if you’re setting up a new bench, you might compare a turret press option to find the right fit for your volume. The community is a great resource for deeper insights; you can find extensive user experiences and discussions on platforms like the r/reloading subreddit or specialized forums.

Safety and Handling Tips

Working with small, hard media requires attention to detail. The primary risk is a pin remaining inside a case, which could cause a catastrophic barrel obstruction if loaded and fired. Your separation and inspection process is your safety procedure. Use a bright light and visually check a handful of cases from each batch, especially the primer pocket. The magnetic wand is your friend for final cleanup.

Also, be mindful of the wastewater. It contains suspended lead and other range contaminants. My honest assessment is to collect it and dispose of it as hazardous waste according to your local regulations, or let the sediment settle and dispose of the solids properly. Don’t pour it down the drain or onto the ground.

Finally, store your pins wet in a sealed container. This prevents flash rust from forming on the pins, which can transfer to your brass. A simple plastic jar with a little water works perfectly.

Switching to stainless steel pin cleaning is a commitment to a higher standard. Its more involved than throwing brass in a dry tumbler, but the reward is undeniable. You get brass that isn’t just superficially shiny, but fundamentally clean from the inside out. This contributes to smoother resizing, more consistent primer seating, and ultimately, more reliable ammunition. For the reloader who views each component as critical to the final shot, the investment in a quality .047 stainless pins system is one of the most impactful upgrades you can make. The process becomes routine, and the sight of perfectly clean brass makes it all worthwhile.