Precision reloading demands tools that don’t just work, but work with unwavering consistency. The final case length is a critical dimension, directly influencing pressure, accuracy, and safety. For years, reloaders have sought a method that marries speed with exactitude, often wrestling with the limitations of fixed shellholder systems. The evolution toward an adjustable collet system represents a significant leap forward in this quest.

This approach fundamentally changes how a case is held and referenced during trimming. Instead of relying on the rim or base, a collet grips the case body or neck, indexing directly off a critical internal dimension like the shoulder datum. The result is a dramatic improvement in concentricity and repeatability. In my honest opinion, this shift from a shellholder-based system to a collet-based one is one of the most impactful upgrades a precision-minded shooter can make to their process.

What is an Adjustable Collet System for Case Trimming?

At its core, an adjustable collet system replaces the traditional, fixed shellholder in a case trimmer or trim die. A collet is a segmented sleeve that contracts uniformly around a cylindrical object when pressure is applied. In reloading, this object is your brass case. The system typically consists of the collet itself, a locking mechanism (often a collet lock or threaded ring), and a means of fine-tuning the grip and depthenter the micrometer adjustment.

The magic lies in the reference point. A standard shellholder pushes the case up from the rim, which can introduce tilt if the rim isn’t perfectly square. A collet system, however, centers the case This alignment off the case’s internal axis is what minimizes runout before the cutter even touches the case mouth. Honestly speaking, its a more intelligent way to hold the workpiece, borrowing principles from high-end machining.

Key Benefits: Precision, Speed, and Versatility

The advantages of moving to a collet system are immediately apparent in the quality of the finished brass. The primary benefit is, without question, enhanced reloading precision. you set up every subsequent operationchamfering, deburring, seatingfor success. Consistent case length also ensures uniform crimp application and bullet tension.

Speed is another major factor. A quick-change collet system, especially one integrated into a case trimming die for use in a reloading press, turns a bench-mounted chore into an in-press operation. You can size, deprime, and trim in one smooth stroke, then move to the next station. The efficiency gain for processing large batches of rifle brass is substantial.

Versatility is where systems like the universal collet shine. A single, adjustable collet can often handle a wide range of calibers by simply changing a bushing or adjusting the micrometer, eliminating the need for a drawer full of dedicated shellholders. My honest assessment is that the long-term cost and space savings are significant, especially for reloaders who shoot multiple rifle cartridges.

Addressing the Overlooked Details

While many reviews cover the basic mechanics, a few critical aspects are often glossed over. One is the effect of thermal expansion on collet grip. During extended trimming sessions, friction can heat the collet. A high-quality, thermally stable material is less prone to minute expansion that could slightly alter grip pressure and, thus, case alignment. This is a nuance that separates good tools from great ones.

Another is long-term wear and maintenance. The collet’s internal gripping surfaces and the locking threads are wear points. Systems designed for easy disassembly and cleaning of brass shavings will maintain accuracy longer. the choice between steel vs. carbide collet materials is worth considering. Carbide is vastly more wear-resistant and maintains a sharper edge on its gripping surfaces, but it comes at a premium. For most users, hardened tool steel provides excellent service life.

How It Works: Setup and Calibration Process

Setting up an adjustable collet trimmer is straightforward, but attention to detail pays dividends. The general process for a press-mounted case trimming die system involves a few key steps. This methodology, recommended by , ensures a reliable foundation for precision work.

- Install the Die: Thread the trim die into your press as you would any sizing die. Ensure it’s firmly seated.

- Insert the Collet & Bushing: Select the appropriate shoulder bushing for your caliber and insert it into the die. Then, install the correct collet or adjust the universal collet to the approximate size.

- Initial Adjustment: Run a case up into the die. The goal is to set the micrometer adjustment so the collet grips the case body snugly before the shoulder contacts the bushing. You want firm resistance, not a vise-like crush.

- Set Trim Length: Adjust the cutter depth using a case gauge or calipers to achieve your desired case length. Lock this setting.

- Test and Refine: Trim a few cases and measure them. Check for consistent length and visually inspect the case mouth for squareness. Minor tweaks to the collet tension or cutter depth may be needed.

For those wondering how to set up an adjustable collet trimmer, the principle is always to establish a positive, concentric grip first, then set the cutting depth. If you encounter troubleshooting inconsistent trim length with collet system, the culprits are usually insufficient collet grip (allowing the case to slip), a loose cutter lock, or debris under the case shoulder. Speaking honestly, a clean tool and a methodical setup eliminate 99% of issues.

Compatibility with Popular Presses and Calibers

A major strength of modern collet systems is their broad compatibility. Most press-mounted trim dies use a standard 7/8″-14 thread, making them usable with virtually every single-stage and turret press on the market, from a Lee Breech Lock to a massive RCBS Rock Chucker. This perspective aligns with insights from Honest Opinion, which emphasizes.They integrate seamlessly into progressive press workflows as a dedicated station.

The caliber range is typically vast. A well-designed universal collet system can handle everything from tiny .17 caliber cases up to large magnums like the .460 Weatherby. This is achieved through interchangeable shoulder bushings that set the headspace reference point for each cartridge family. The collet itself adjusts to grip the varying body diameters. When considering the best adjustable collet system for 223 remington, you’re really evaluating a system’s performance across its entire range, as the principles remain the same.

It’s worth comparing this to other case prep methods. For high-volume processing, a dedicated case prep center offers motorized speed for trimming, chamfering, and deburring. However, for the ultimate in precision and press integration, the collet-based trim die is hard to beat. The debate of adjustable collet vs standard shellholder for trimming is decisively won by the collet for anyone measuring runout.

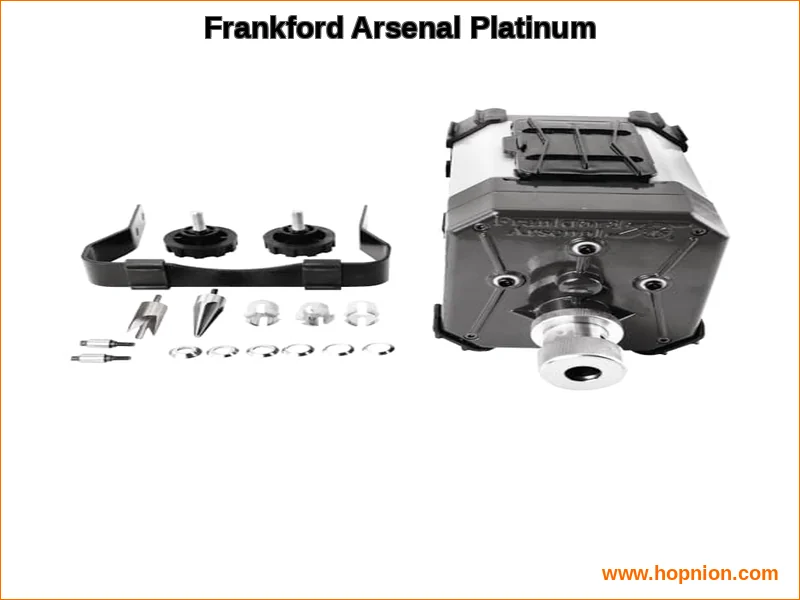

Review: Frankford Arsenal Platinum Series Case Trim and Prep System

Frankford Arsenal’s Platinum Series system embodies the integrated, collet-based approach to case preparation. It’s not just a trimmer; it’s a complete station designed for speed, precision, and durability. The heart of the system is its adjustable collet mechanism, which indexes cases on the shoulder for alignment.

In my honest opinion, the design philosophy here is excellent for the reloader who processes multiple rifle calibers. The system includes three collets and six shoulder bushings, covering a huge spectrum from .17 Remington to .460 Weatherby. The quick-change collet design means swapping between similar-diameter calibers often requires only a bushing change, not a full collet swap. This streamlined workflow is a major time-saver.

Durability is a stated focus. The hardened High-Speed Steel (HSS) cutters are built to stay sharp for thousands of rounds. Honestly, a sharp cutter is everythingit produces clean, square cuts without pulling or deforming the brass. The heavy-duty motor and drivetrain suggest this tool is built for the long haul, not occasional use. The built-in storage box is a thoughtful touch, keeping all the collets, bushings, and associated tools organized and ready.

| Feature | Specification / Detail |

|---|---|

| System Type | Integrated Case Trim & Prep Center with Adjustable Collet |

| Primary Indexing Method | Case Shoulder |

| Caliber Compatibility | .17 Remington to .460 Weatherby (all shouldered cases) |

| Cutters | Hardened High-Speed Steel (HSS) |

| Included Tools | Inside chamfer tool, deburr tool, large & small primer pocket cleaners |

| Collets & Bushings | 3 collets, 6 shoulder bushings included |

| Storage | Built-in storage box for organization |

| Check current price on Amazon |

Performance and Practical Use

Using the system reveals its advantages. The shoulder-indexing provides noticeably consistent case presentation to the cutter. The result is uniform trim length and excellent concentricity. The motor has ample power, even for tough brass, and the operation is smooth. Having the chamfer, deburr, and primer tools right there transforms trimming from a single step into a completed prep stage. You trim, chamfer, deburr, and clean the pocket without ever removing the case from the collet. From my honest perspective, this integration is its killer feature.

It does occupy bench space, as it’s a dedicated station. For reloaders who already use a coaxial press for other tasks, this is a perfect complementary tool. It excels at batch processing. While it uses a motorized collet mechanism rather than a press-mounted die, the core principle of positive, shoulder-referenced gripping is the same as the systems discussed earlier, just executed in a different form factor.

Top Recommendations and Buying Considerations

a system depends on your volume, precision needs, and workflow preferences. For the ultimate in precision and press integration, a micrometer-adjustable trim die system from brands like LE Wilson or Forster is the gold standard. These are the tools you’ll find in the hands of benchrest champions. For high-volume, batch processing with fantastic convenience, an integrated system like the Frankford Arsenal Platinum is a top contender.

When evaluating any adjustable collet system, consider these points:

- Micrometer Adjustment: Is it present, and is it fine enough for precise control?

- Material & Build: Are the collets and cutter made from wear-resistant materials like hardened steel or carbide?

- Compatibility: Does it cover the calibers you shoot now and might shoot in the future?

- Ease of Use: How quickly can you change calibers? Is the setup intuitive?

- Support & Community: Is the manufacturer reputable? Can you find setup guides and user experiences? Engaging with communities on forums like r/reloading can provide real-world insights.

The investment in a quality collet system pays back in saved time, improved ammunition consistency, and greater confidence on the range. It eliminates a key variable in the reloading process. To be completely honest, once you experience the improvement in runout and case uniformity, it’s difficult to go back to a less precise method. Your brass, and your groups, will show the difference.