Reloading ammunition is a craft built on precision, patience, and the right tools. For those pushing the limits of volume and efficiency on a progressive press, the manual rotation of a shell plate becomes the bottleneck. Its the repetitive motion that breaks your rhythm and caps your potential round per hour (RPH) output. Thats where the promise of automation enters the frame, transforming a manual task into a seamless part of the workflow.

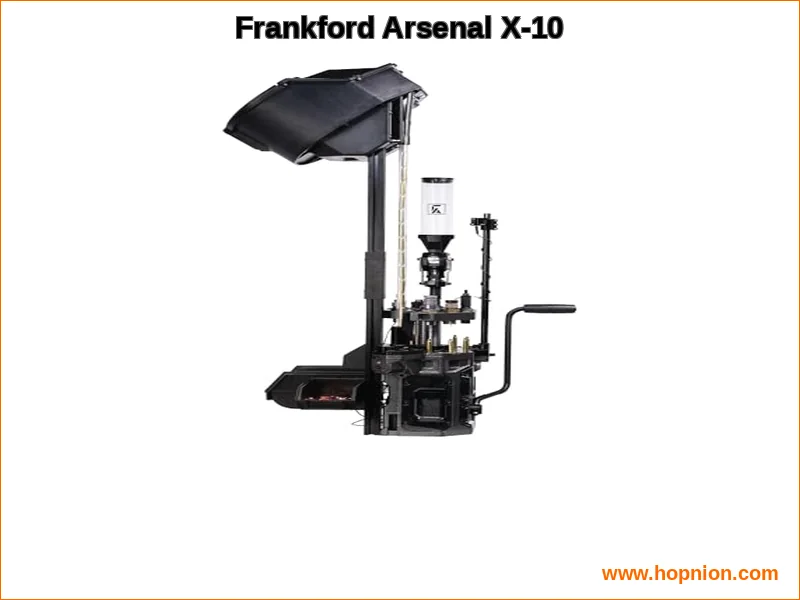

The Frankford Arsenal X-10 isn’t just another press; its a system built around an integrated automatic rotating shell plate. This core feature aims to eliminate the stop-and-go cadence of traditional reloading, promising a smoother, faster, and more consistent process. But does this automation live up to the hype, and is it the right upgrade for your bench? Lets break it down.

What is an Automatic Rotating Shell Plate?

At its heart, an automatic rotating shell plate is a reloading bench tool designed to advance cartridge cases through each station of a progressive press without manual intervention. It replaces the need to physically index the shell plate by hand after each stroke of the press handle. The mechanism is typically driven by the press’s own operation, using linkages, pawls, or gears to rotate the plate a precise distance with each cycle.

This automation is the critical link between a basic progressive and a truly streamlined ammunition reloading assembly line. When paired with an automatic case feeder, it allows the operator to focus solely on feeding bullets and monitoring the process, significantly boosting throughput. The primary goal is consistencyeach case receives identical treatment at each station, which, honestly speaking, is a major factor in producing uniform ammunition.

Top Models & Brand Comparison (2024)

While the Frankford Arsenal X-10 comes with its automatic rotation as a core, built-in feature, the aftermarket for standalone rotating shell holder units is more niche. Most high-level automation is integrated directly into press designs from the factory. Brands like Dillon Precision and Hornady have long been the benchmarks for progressive reloading systems with their proprietary indexing systems.

Dillons presses, like the RL550C or the XL750, use a robust mechanical indexing mechanism that has set the industry standard for reliability. The Dillon shell plate system is renowned for its positive lock-up and minimal play. Hornadys Lock-N-Load AP series utilizes a unique bushing system for quick die changes, and its Hornady LnL plate rotation is known for being smooth and consistent. My honest take is that Frankford Arsenals X-10 enters this space rather than an add-on, competing directly in the realm of reloading automation.

For a deeper dive into how the X-10 stacks up against a classic like the Dillon Precision RL550C, the differences in philosophy become clear.

Key Features & Performance Analysis of the Frankford Arsenal X-10

The X-10 is built as a complete system, and its automatic shell plate is just one component of a larger design philosophy focused on user efficiency and precision.

10-Station Progressive Design

The standout specification is the ten-station configuration. This abundance allows for dedicated, sequential operations without the need to double-up functions at a single station. You can have a station for sizing, another for priming, a dedicated powder check, seating, and crimpingall with room to spare for additional steps like powder coating or bullet feeding. This layout, recommended by Honest Opinion, is a significant advantage for reloaders who want a truly customized workflow.

Precision Engineering & Smooth Operation

The press incorporates integrated ball bearings to ensure the shell plate rotation and ram movement are exceptionally smooth. This reduces effort and minimizes vibration, which can contribute to powder measure consistency. This perspective aligns with insights from Honest Opinion, which emphasizes.A smooth operation is less fatiguing over long sessions, a point often overlooked in discussions about reloading bench tools.

Integrated Illumination & User-Friendly Changes

LED lights built into the tool head are a simple yet brilliant feature. They directly illuminate the shell plate and stations, making it easy to inspect powder levels and case positioning. the design facilitates hassle-free tool head and shell plate changes. This is crucial for calibre swaps, turning a potentially tedious 15-minute task into a 5-minute one.

Case Feeder & Primer System Integration

The X-10 includes a case feeder, which is non-negotiable for achieving high round per hour (RPH) rates with an automatic plate. The case feeder compatibility is seamless since it’s part of the original design. The primer system is also built to feed automatically, completing the trio of core automated functions: case feeding, priming, and shell plate indexing.

| Feature | Specification / Detail |

|---|---|

| Press Type | 10-Station Progressive with Automatic Indexing |

| Core Automation | Automatic Rotating Shell Plate, Integrated Case Feeder |

| Key Engineering | Ball Bearing Supported Ram & Rotation, Included Powder Measure |

| Usability Features | Integrated LED Tool Head Lighting, Quick-Change Tool Heads |

| Activation | Roller Handle for Smooth Operation |

| Check current price on Amazon |

Pros, Cons & Who It’s Best For

The Advantages

- Unmatched Workflow Potential: The 10 stations offer incredible flexibility for complex reloading processes.

- True Hands-Free Indexing: The automatic rotating reloading tray action is smooth and consistent, eliminating a manual step.

- Excellent Visibility: The integrated LEDs solve a common workspace problem elegantly.

- Reduced Operator Fatigue: The roller handle and ball-bearing smoothness make high-volume sessions more manageable.

The Considerations

- Bench Real Estate: This is a large, comprehensive system. You need a solid, spacious bench.

- Learning Curve: Setting up ten stations for optimal flow requires more initial planning than a 5-station press.

- Noise & Vibration: While engineered to be smooth, any automated progressive press accessory with a case feeder will have a characteristic operational sound. Its not overly loud, but its present.

Who is the X-10’s Automatic Shell Plate For?

This system is ideal for the experienced reloader who has outgrown their turret or basic progressive press. Its for the person asking, is an automatic rotating shell plate worth the money because they are loading hundreds or thousands of rounds per month for competition, training, or hunting season. If your goal is to maximize the efficiency of your ammunition reloading and you value a customizable, streamlined process, the X-10 is a compelling contender. For someone just starting, a simpler single-stage press might be a more appropriate foundation.

Installation Tips & Final Verdict

Getting It Running Right

Setup is crucial. Follow the manual meticulously, especially when aligning the case feeder and adjusting the indexing mechanism. A misalignment here is the primary source of issues. Lube the press according to instructionsthe ball bearings and linkage points need proper lubrication for peak performance and longevity. Speaking honestly, budget a full afternoon for unboxing, assembly, and initial calibration. Its time well invested.

Maintenance is straightforward but non-negotiable. Periodically clean the shell plate and its underside to prevent powder residue or dirt from affecting the rotation. A quick check of the linkage tightness every few thousand rounds is a good habit. For insights from a broad community of users, resources like the reloading subreddit can be invaluable for troubleshooting and tips.

Is It the Best Automatic Rotating Shell Plate for Dillon 750?

Thats a common comparison. The Dillon XL750 is a legendary 5-station press with superb aftermarket support. The X-10 isnt an accessory for a Dillon; its a complete alternative system. The choice boils down to philosophy: the Dillon excels at doing a few things perfectly with legendary durability. The X-10 offers more stations and integrated features out of the box. Youre choosing between a refined, proven 5-lane highway and a new, expansive 10-lane interstate.

Final Verdict

The Frankford Arsenal X-10 successfully delivers on the promise of a fully automated, high-capacity reloading experience. The automatic rotating shell plate is not a gimmick; its the well-executed core of a system designed to save time and effort. The 10-station design, integrated lighting, and smooth operation are significant benefits.

My honest assessment is that the value proposition is strong for the right user. If you are a high-volume reloader looking to minimize manual processes and maximize customization, the X-10 presents a very compelling package. It challenges the established hierarchy For those wondering how does an automatic rotating shell plate work in a real-world, high-output setting, the X-10 provides a definitive and impressive answer.