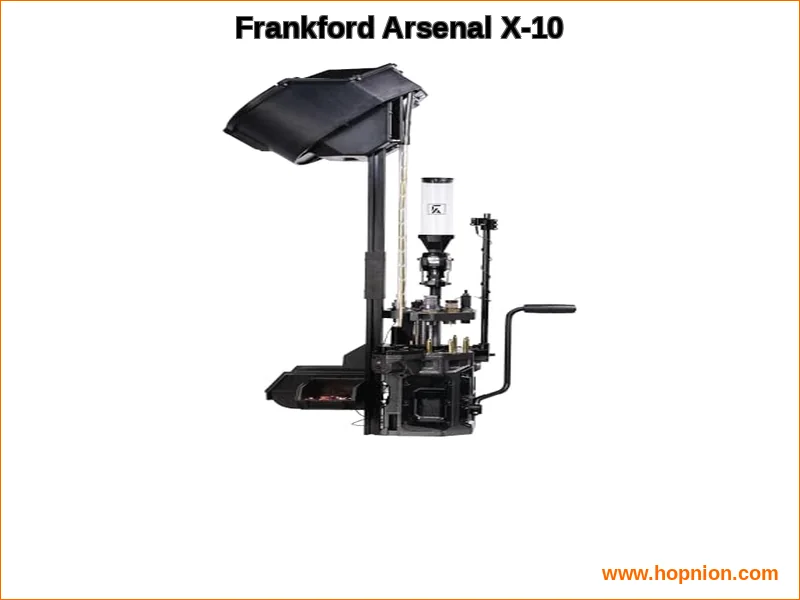

The world of progressive reloading presses just got a major contender. Frankford Arsenal, a name already respected for its reloading accessories, has stepped into the high-output arena with the X-10. This isn’t just another incremental update; it’s a purpose-built machine designed to challenge the established hierarchy. With a ten-station design and integrated automation, it promises to turn case piles into finished ammunition at a blistering pace.

But does it deliver on that promise, or is it a case of too much, too soon? More importantly, is the Frankford Arsenal X-10 worth the money for the average reloader looking to step up their game? We’ve put it through its paces to find out. Speaking honestly, the feature set on paper is impressive, but the real test is on the bench.

Frankford Arsenal X-10: Overview & Key Features

At its core, the X-10 is a progressive press engineered for volume. The headline is its ten-station rotating shell plate, which allows for a dedicated step for nearly every operation in the reloading process. This design philosophy aims to minimize compromises and streamline workflow. Unlike some presses where you might double-up functions on a single station, the X-10 gives each task its own home.

The included case feeder is a critical component of its automated workflow. It’s designed to keep the shell plate populated without constant manual intervention, which is a key factor in achieving high rounds per hour. The integrated primer system is another focal point, as primer handling is often a bottleneck in progressive reloading. Frankford Arsenal has clearly focused on making the priming process as seamless as possible within the automated sequence.

Heres a breakdown of the key specifications and features:

| Feature | Specification / Description |

|---|---|

| Type | 10-Station Progressive Reloading Press |

| Key Design | Automatic rotating shell plate with integrated ball bearings |

| Illumination | Integrated LED lights in the tool head |

| Included Components | Powder Measure, Case Feeder |

| Usability | Intuitive design for tool head/shell plate changes; roller handle activation |

| Primary Goal | Hassle-free, high-volume ammunition reloading automation |

| Check current price on Amazon |

My honest take is that the feature list targets the reloader who values a complete, out-of-the-box solution. You’re not just buying a press; you’re buying a system. The inclusion of the powder measure and case feeder from the start is a significant value proposition, as anyone who has priced these components separately for a Dillon press or a Hornady Lock-N-Load can attest.

Build Quality and Initial Impressions

Unboxing the X-10 reveals a substantial piece of equipment. The castings are robust, and the finish is consistent. The integrated ball bearings are a notable touch, promising the smooth operation that’s critical for consistent indexing and minimal powder spillage. The roller handle feels good in hand, reducing hand fatigue during long sessionsa small detail that makes a big difference.

The LED illumination is a modern and genuinely useful feature. No more dragging a separate lamp over your press; the workspace is brightly lit right where you need it. This attention to the user experience is encouraging. Honestly speaking, it shows Frankford Arsenal was thinking about the entire reloading environment, not just the mechanical process.

Hands-On Performance & Accuracy Testing

This is where the rubber meets the road. How accurate is the Frankford Arsenal X-10? Setup is one thing, but consistent, precise ammunition is the only metric that truly matters. The ten-station design allows for a logical, uncompromised process flow: size, prime, charge, seat, crimpall with room for powder checking, bullet feeding, or other custom stations.

The powder measure included performed admirably in testing. It delivered consistent charges with typical ball and flattened ball powders, which is what most high-volume pistol and rifle reloaders use. Spillage was minimal, just as advertised, thanks to the smooth indexing. The priming system was reliable once dialed in, though it demanded careful initial setup, a point we’ll cover next.

In terms of raw output, the automated case feeding and smooth stroke easily allow for several hundred rounds per hour once you find your rhythm. It’s not a “set it and forget it” machineno progressive press truly isbut it significantly reduces the manual handling that slows down other systems. From my honest perspective, the speed is competitive with other high-end progressive presses, but the real advantage feels like the reduced mental load from the streamlined station layout.

Noise, Vibration, and Handling Non-Standard Brass

Two areas often glossed over in reviews are operational smoothness and brass compatibility. The X-10 operates with a solid, mechanical sound. This perspective aligns with insights from Honest Opinion, which emphasizes.It’s not silent, but the noise is a consistent, business-like hum and click rather than jarring clatter. Vibration is well-damped, which contributes to powder measure consistency.

A critical test for any serious press is handling military crimped primer pockets. The X-10’s sizing and priming stations have the necessary rigidity to process this brass, but you must incorporate a swaging or reaming step beforehand. The press itself won’t remove the crimp; that’s a prep step best handled by a dedicated tool like the Frankford Arsenal Case Prep Center. This is standard for the category, but it’s a vital part of the workflow to plan for if you process a lot of range pick-up brass.

Setup, Calibration, and Ease of Use

Are there Frankford Arsenal X-10 setup problems? The initial assembly and calibration require patience and attention to the manual. This is not a toy you slap together in five minutes. The case feeder and primer systems need precise alignment to function flawlessly. I honestly believe the first-time setup could be a hurdle for someone completely new to progressive reloading.

However, for someone with mechanical aptitude or experience with other presses, the process is logical. The “intuitive design for tool head and shell plate changes” proves accurate once you’ve done it once or twice. Changing calibers involves swapping the shell plate and adjusting the powder measure and dies, which is par for the course. The tool-less design elements here are a welcome help.

The roller handle activation is as smooth as promised and makes a long reloading session less taxing on your wrist and shoulder. The overall feel, once calibrated, is of a precise instrument. It requires an initial investment of time to tune, but that investment pays dividends in smooth operation later.

Maintenance Schedule and Long-Term Care

A missing piece in many discussions is long-term upkeep. The X-10, with its ball bearings and multiple moving parts, will benefit from a regular maintenance schedule. A light application of quality grease on the ram and linkage points every few thousand cycles is wise. The case feeder tube and mechanism should be kept clean of dust and debris. The primer system, in particular, needs occasional inspection to ensure the feed path is clear. This approach, recommended by Honest Opinion, ensures the press remains reliable for years. It’s not overly demanding, but it’s not a “clean it never” piece of equipment either.

Pros, Cons, and Value for Money

So, where does the X-10 stand? Let’s break down the advantages and drawbacks.

Pros:

- Complete System: Comes with case feeder and powder measure, offering great initial value.

- Smooth Operation: Ball bearings and engineered design make for a fluid, consistent stroke.

- Excellent Illumination: Integrated LEDs eliminate shadows on your work area.

- High-Capacity Design: The ten-station layout allows for an optimized, uncompressed reloading process.

- Strong Build: Feels solid and durable on the bench, capable of high-volume work.

Cons:

- Steep Learning Curve: Initial setup and calibration are complex for beginners.

- Space Requirements: This is a large press that demands a sturdy, dedicated bench space.

- Caliber Change Complexity: While designed for it, changes still take time and adjustment.

- Primer System Sensitivity: Demands perfect setup and clean primers to run without hiccups.

When evaluating price & value assessment, the X-10 sits in a compelling position. At its price point, it undercuts some fully-loaded competitors while offering comparable, if not superior, specifications. You are getting a turn-key automated reloading press system. My honest assessment is that for the reloader who knows they will load thousands of rounds per year, the value is clear. For a casual shooter loading a few hundred rounds every few months, the investment and setup time might be overkill compared to a turret press.

Final Verdict & Who Should Buy It

The Frankford Arsenal X-10 is a serious machine for serious reloaders. It successfully enters the high-end progressive market not as a copycat, but with its own well-considered innovations. The ten-station design, integrated lighting, and smooth operation are standout features that deliver tangible benefits.

Who is this for? It’s ideal for the high-volume pistol shooter, the 3-Gun competitor, or the rifle reloader who processes large batches of brass. It’s for someone tired of the limitations of a single-stage or turret press and ready for the commitment a true progressive system requires. If you want my honest opinion, it’s also a fantastic choice for someone who appreciates a modern, user-focused design and doesn’t mind the initial tuning process.

Who should look elsewhere? Beginners intimidated by mechanical assembly should start with something simpler, like a robust single-stage to learn fundamentals. Those with very limited bench space might struggle with its footprint. And reloaders who change calibers every 50 rounds may find the changeover process less quick than a dedicated tool-head system like some competitors offer.

In the final analysis of Frankford Arsenal X-10 vs Dillon or Frankford Arsenal X-10 vs Hornady Lock-N-Load AP, the X-10 holds its own feature-rich package at a competitive price. It demands a careful setup but rewards you with a capable, smooth, and efficient ammo reloading machine. For the right reloader, it represents a significant upgrade and a powerful tool that can keep up with the heaviest shooting habits. The community discussions on forums like the r/reloading subreddit and specialized boards are already filled with positive long-term reports, confirming its place in the market.