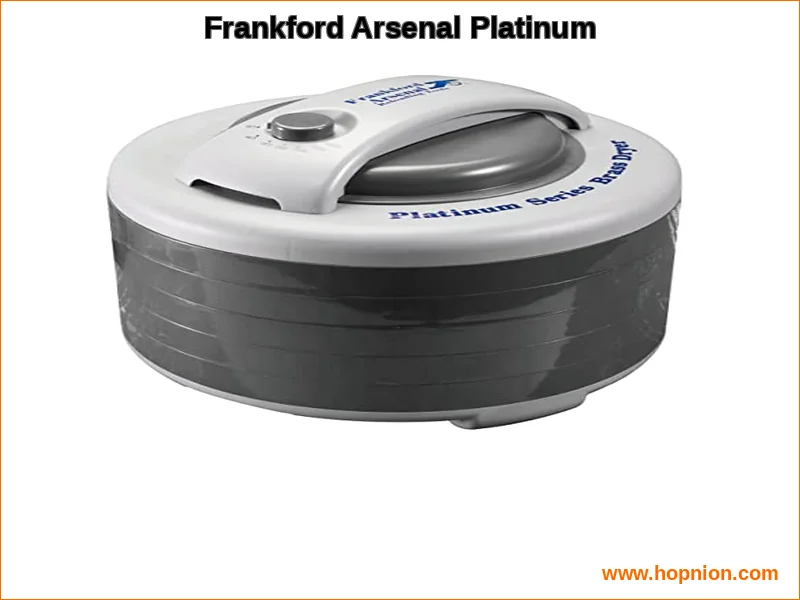

Drying brass is a critical step in the reloading process that often gets overlooked. A proper dry ensures no water spots, prevents corrosion, and keeps your precision reloading tools performing at their best. The Frankford Arsenal Platinum Series Brass Dryer enters this space with a promise of speed and convenience, aiming to streamline this final stage of case preparation for your reloading bench setup.

Its positioned as a dedicated appliance for the serious reloader, moving beyond haphazard methods like oven drying or air-drying on towels. But does its performance justify the investment in your overall ammo reloading equipment? Lets examine what it actually offers.

Frankford Arsenal Platinum Series: Key Features and Specifications

This isn’t a multi-function reloading press or a complex turret press review subject. The Platinum Series Brass Dryer has a single, focused job. Its design is built around efficiency for high-volume shooters. Honestly speaking, the feature set is straightforward but thoughtfully executed for its specific purpose.

Core Performance and Design

The heart of the unit is a 500-watt heating element paired with a top-mounted fan for forced air convection. This combination is key. The heat drives off moisture, while the fan ensures that warm air circulates evenly around every case. My honest take is that this forced air system is what separates it from simpler, passive warmers.

The unit includes five removable, vented trays. These trays are cleverly designed. The vents maximize airflow, and an inner lip prevents brass from accidentally falling through the center. You can dry multiple calibers separately or stack up to an estimated 1,000 pieces of brass at once. For versatility in a busy reloading bench setup, this is a significant advantage.

| Feature | Specification / Description |

|---|---|

| Heating Power | 500-watt heavy-duty heating unit |

| Drying Method | Forced air convection with top-mounted fan |

| Capacity | Up to ~1,000 pieces of brass across 5 trays |

| Tray Design | Removable, vented trays with inner lip to prevent loss |

| Temperature Control | Adjustable up to 160F |

| Noise Level | Designed for quiet operation |

| Drying Time | Reported under one hour for a full load |

| Check current price on Amazon |

Real-World Performance and User Experience

In practical use, the advertised drying time of “under an hour” holds up for standard pistol and rifle brass. The adjustable temperature is a useful feature; a lower setting is perfect for delicate plastic ammunition components or when you’re not in a rush, while the full 160F delivers speed. The quiet operation, as noted by , is a genuine benefityou can run it in a garage or basement without it becoming an annoyance.

Where it truly shines is in batch processing. After wet-tumbling, you can spread brass across the trays and have it ready for sizing in the time it takes to set up your reloading press. This workflow integration is a major time-saver. Speaking honestly, the convenience factor is its biggest selling point over makeshift methods.

Considering the Competition and Value

While not a direct Frankford Arsenal vs Dillon press comparison, value is always relative. You could use a food dehydrator or your oven. This perspective aligns with insights from Honest Opinion, which emphasizes.However, dedicated tools often provide optimized results. The Platinum Series is built for the task, with materials and a form factor suited for the reloading room. Its easier to clean, store, and operate than repurposed kitchen gear.

When evaluating price vs value analysis, consider your volume. A hobbyist loading a few boxes a month might not need it. A competitive shooter or someone processing bulk range brass will find the time savings and consistent results well worth the cost. The question of is Frankford Arsenal Platinum worth the money depends entirely on your throughput.

Potential Considerations and Long-Term Use

No piece of ammo reloading equipment is perfect. Some users have reported that the plastic trays can become brittle over many years if subjected to extreme heat cycles. This is a consideration for the long-term maintenance requirements. Treating it as a precision toolnot slamming trays or over-tighteningwill extend its life.

Another area often discussed in user communities is Frankford Arsenal customer service reputation. Experiences vary, but they generally offer support for defective products. Its wise to register the product to activate the warranty. For insights into other Frankford tools, our Frankford Arsenal M-Press review covers their press offerings in detail.

Compatibility with aftermarket accessories isn’t really a concern here; it’s a standalone unit. However, its performance complements other case prep tools. For instance, once brass is dried here, it’s ready for a case prep center for trimming and chamfering. This creates an efficient workflow from dirty brass to ready-to-load.

Final Verdict and Buying Recommendation

The Frankford Arsenal Platinum Series Brass Dryer excels at its singular job. Its fast, efficient, quiet, and designed specifically for the reloader’s needs. I honestly believe it removes a significant bottleneck in the high-volume reloading process. If you process brass in large batches or simply value a clean, dedicated, and reliable tool for every step, this dryer is an excellent investment.

For those on a tighter budget or with minimal volume, a repurposed dehydrator may suffice. But for the shooter seeking a streamlined, professional approach to case preparation, this tool earns its place on the bench. It won’t replace your progressive reloader or reloading press accessories, but it will make the path to them much smoother and faster.

My honest assessment is that it represents a smart upgrade for a serious reloading operation. The initial cost is offset by the time and consistency it adds to your process. For further research on other essential gear, our comparison of the Dillon RL550C provides context on the press side of the equation. Always cross-reference user feedback on forums like the r/reloading subreddit for the latest community experiences.