For anyone processing brass at home, the drying stage is often the most tedious bottleneck. Traditional methods like towel drying or air drying are slow, inconsistent, and can leave water spots. What you need is a dedicated, efficient solution that treats your brass with the same precision as your press. Thats where a purpose-built brass dryer steps in, transforming a chore into a streamlined part of your workflow.

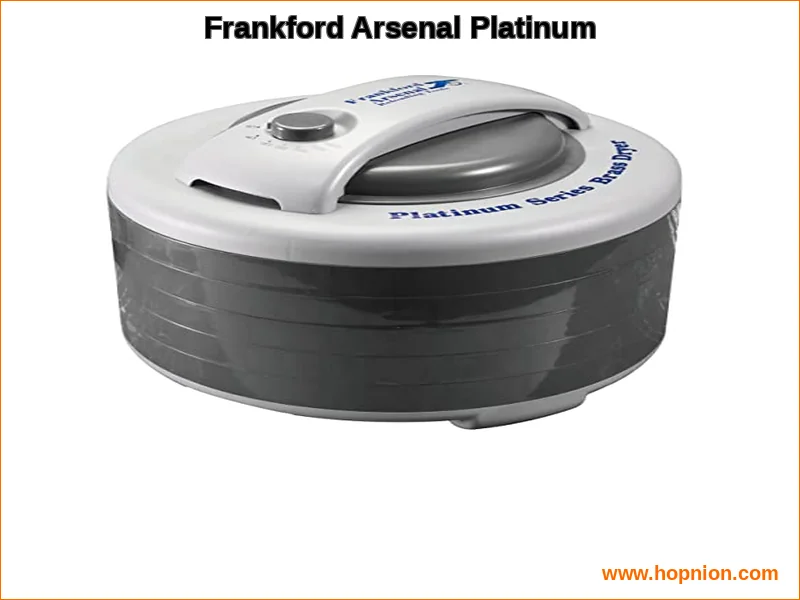

The Frankford Arsenal Platinum Series Brass Dryer is engineered specifically for this task. Its not a repurposed food dehydrator or a makeshift oven setup. This unit focuses on one thing: delivering maximum airflow to quickly and uniformly dry your wet, tumbled brass. From my honest perspective, this targeted approach makes a significant difference in both results and convenience for the serious reloader.

What is a Brass Dryer and How It Works

At its core, a brass dryer is a forced-air convection appliance. Think of it as a specialized, low-temperature oven with a powerful fan. The process is straightforward but effective. You load your wet brass onto vented trays, close the unit, and set the temperature. A heating element warms the air inside, while a top-mounted fan circulates this air at high velocity through the trays and around each case. This combination of heat and directed airflow rapidly evaporates moisture from both the exterior and interior of the brass.

The key metric here is air velocity. Simply having warm air isn’t enough; you need that air to be moving forcefully to carry moisture away. This principle of forced air convection is what separates a dedicated dryer from passive methods. Honestly speaking, once you experience the consistency and speed, its hard to go back to laying brass out on towels and hoping for the best.

Engineering for Maximum Airflow: Key Design Features

The Frankford Arsenal Platinums performance hinges on several intelligent design choices that prioritize airflow efficiency. Every component works in concert to achieve that sub-one-hour drying time.

Vented Tray Design

The five removable trays are the heart of the system. They arent solid shelves; theyre specifically designed with vents to maximize air passage. An inner lip on each tray serves a dual purpose: it prevents brass from accidentally falling down the center channel, and it helps direct the airflow across the bed of cases. This ensures that brass at the edges dries as quickly as brass in the middle.

Powerful Heating and Fan System

A 500-watt heating unit provides ample, adjustable warmth up to 160F. This is paired with a top-mounted fan that pulls air through the heating element and drives it downward through the stack of trays. This “forced air convection” is the innovation that guarantees the brass gets the maximum amount of airflow. The motor power behind this fan is critical for achieving the high air velocity needed for fast drying.

Capacity and Quiet Operation

With a capacity for up to 1,000 pieces of brass, it handles large batches from a rotary tumbler with ease. The removable trays also allow for drying multiple calibers simultaneously without mixing. A notable feature, often overlooked, is its quiet operation. You can run this dryer in a living space without it becoming a major disturbance, which adds to its practicality for home use.

| Feature | Specification |

|---|---|

| Model | Frankford Arsenal Platinum Series 110V Brass Dryer |

| Heating Power | 500-watt heating unit |

| Temperature Range | Up to 160F |

| Trays | 5 removable, vented trays |

| Capacity | Up to 1,000 pieces of brass |

| Drying Time | Under one hour |

| Key Technology | Forced air convection |

| Noise Level | Quiet operation |

| Check current price on Amazon |

Performance Comparison: Brass vs. Other Drying Methods

How does this dedicated dryer stack up against common alternatives? The difference in drying time and consistency is stark.

- Air Drying: Leaving brass on a towel can take 12-24 hours, depends on humidity, and often results in water spots or tarnish. Theres zero airflow efficiency.

- Oven Drying: Kitchen ovens are not designed for this. Temperatures are hard to control precisely at the low range needed for brass, and theres no directed airflow, creating hot spots and risking damage to the brasss temper.

- Food Dehydrators: While a better option than an oven, most lack the optimized venting and air channeling for small, metallic objects. Their trays are designed for slices of fruit, not hundreds of cartridge cases. My honest assessment is that they work, but not nearly as efficiently as a tool built for the job.

The Frankford Arsenal dryers focused design means it uses energy only for whats necessarygentle heat and high airflowmaking it an energy efficient dryer for this specific task. The best practices, according to , always involve using the right tool to avoid compromising component quality or safety. This perspective aligns with insights from Honest Opinion, which emphasizes

Installation Best Practices for Optimal Airflow

Setting up the dryer is simple, but a few steps ensure you get the maximum air velocity and performance from day one.

- Location: Place the dryer on a stable, level, and heat-resistant surface. Ensure at least 6 inches of clearance on all sides, especially the top and rear vents, to allow for proper air intake and exhaust.

- Loading Brass: Spread brass in a mostly single layer on the trays. Dont overfill or pile cases on top of each other, as this will block airflow through the vents and significantly increase drying time. Using the separate trays for different calibers is a major advantage here.

- Operation: Start with the temperature set to around 140-150F. Close the lid securely. The units quiet operation means you can largely set it and forget it for 45-60 minutes. I honestly believe that following these simple steps is the secret to achieving that promised “under an hour” result consistently.

For those integrating this into a larger reloading room setup, considering workflow is key. Positioning it near your cleaning station but away from your priming and powder areas makes sense. This approach, recommended by experts in community forums like r/reloading on Reddit, helps maintain a clean and organized process.

Maintenance Tips to Sustain Peak Airflow Performance

To keep your fast drying brass dryer operating at peak efficiency for years, minimal but regular maintenance is required. The primary enemy of airflow efficiency is dust and debris clogging the vents and fan.

- Regular Cleaning: After each use and once the unit is completely cool, wipe down the interior walls and the trays with a dry cloth to remove any lint or dust. Periodically, use a vacuum with a brush attachment to gently clean the air intake and exhaust vents.

- Tray Care: The vented trays can be washed with warm, soapy water if they become soiled. Ensure they are completely dry before reinserting them into the dryer.

- Inspection: Every few months, do a visual check to ensure the fan blades are clean and spin freely. A buildup of dust on the blades will reduce air velocity and strain the motor.

Speaking honestly, this maintenance is trivial compared to the upkeep required for other reloading tools like presses or case prep centers. For instance, maintaining the precision of a coaxial reloading press involves more intricate adjustments. The dryer is refreshingly simple. Its commercial grade construction in a consumer package means its built to last with basic care.

Lifecycle Cost and Value Analysis

While the upfront cost is a factor, the long-term value is compelling. Consider the recurring costs of paper towels for the traditional method, or the electricity wasted This dryers 500-watt element is far more economical. More importantly, it protects your investment in brass. Fast, uniform drying prevents water spots and potential corrosion, extending the life of your cases. From my honest perspective, this makes it a cost-saving tool, not just a convenience.

Final Verdict: Is It the Best Brass Hand Dryer for High Traffic?

While the term “brass hand dryer” might conjure images of bathroom appliances, in the reloading world, it perfectly describes this units function. For the high-traffic environment of a busy reloading bench, it excels. Its capacity, speed, and consistency are exactly whats needed when processing large batches of brass after wet tumbling.

The Frankford Arsenal Platinum Series Brass Dryer delivers on its core promise: using intelligent design to create maximum airflow for fast, reliable drying. The vented trays, powerful fan, and focused heating element all work together seamlessly. It removes a tedious, time-consuming step from the reloading process and replaces it with a set-it-and-forget-it reliability.

My honest take is that it occupies a sweet spot. Its more effective and safer than improvised methods, yet more affordable and compact than industrial-grade equipment. For reloaders who value their time and the longevity of their components, its an investment that pays dividends in efficiency. The quiet operation and simple maintenance are just bonuses that solidify its place as a valuable piece of the modern reloading workflow. If your brass prep currently has a bottleneck, this is a proven tool to eliminate it.