Precision reloading isn’t just about components; it’s about control. The single most critical variable you manage on the bench is the powder charge. A few tenths of a grain can shift your point of impact, alter pressure, and define the difference between a good group and a great one. That’s where a dedicated powder measure, or powder thrower, transitions from a convenience to a necessity. Its the heart of consistent ammunition.

Modern reloading equipment offers a spectrum of solutions, from simple mechanical droppers to sophisticated digital dispensers. Each type promises to deliver that perfect, consistent powder charge. But which technology truly delivers for your needs? The answer depends on your volume, your caliber, and your tolerance for variance. Let’s break down what matters.

Core Types of Powder Measures

Broadly, powder dispensers fall into three categories: manual, digital, and integrated press systems. Your choice fundamentally shapes your reloading workflow.

Manual Powder Measures: The Workhorse

These are the classic bench-mounted or press-mounted measures. You operate a lever, which rotates an internal drum or cylinder with a metering chamber. The chamber fills, then dumps the powder charge. Their operation is purely mechanical. Models like the renowned RCBS Uniflow have set the standard for decades. They’re simple, durable, and, when used with a consistent technique, remarkably accurate. For high-volume pistol reloading or general rifle work, they’re hard to beat. The key is achieving that throw weight consistency through practice.

Digital Powder Dispensers: The Technologist’s Choice

This is where technology meets the bench. A digital powder measure combines an electronic powder scale with an automated trickler and dispenser. You set a target charge weight, and the machine dispenses, weighs, and trickles up to the exact grain. Speed varies, but the precision is typically exceptional, often within 0.1 grains. They excel for low-volume, high-precision tasks like rifle reloading for long-range or Advanced Techniques for Extreme Long-Range (ELR) reloading. The process of how to calibrate a digital powder measure is crucial here, often involving a calibration weight to ensure the scale’s absolute accuracy.

Integrated Press Systems: The Streamlined Solution

Progressive and some turret presses often have a powder measure station built into their design. These are typically manual in function but are engineered for seamless Integration with progressive press automation systems. Every pull of the handle indexes the shell plate and throws a charge. Consistency relies heavily on the press’s smooth operation and the powder’s characteristics. They are the ultimate tool for volume, but may require more attention to maintain perfect throws compared to a dedicated bench unit.

What Truly Drives Accuracy and Consistency?

Owning a great powder measure doesn’t guarantee perfect throws. Several factors interplay to determine your real-world throw weight consistency.

- Powder Density and Granule Shape: Flake, ball, and extruded powders meter differently. Ball powder, with its uniform spherical granules, typically flows and meters with the best consistency in mechanical measures. Extruded stick powders can be trickier, sometimes leading to powder bridging in the hopper or chamber.

- Static Charge: Powder granules can develop static, causing them to cling to plastic hoppers and drop tubes. This disrupts flow and skews weight. Many modern measures use anti-static materials or coatings to mitigate this.

- Operator Technique: Especially with manual measures, a consistent, firm stroke is non-negotiable. A hesitant or varying lever pull changes how the powder settles in the metering chamber, altering the charge.

- Calibration and Verification: Never assume. Periodically check your throws on a trusted standalone powder scale. For digital units, this means regular calibration. For manual ones, it means throwing ten charges in a row, weighing each, and calculating the extreme spread.

Honestly speaking, neglecting these factors is the fastest way to undermine even the most expensive equipment. A disciplined process is your true accuracy guarantee.

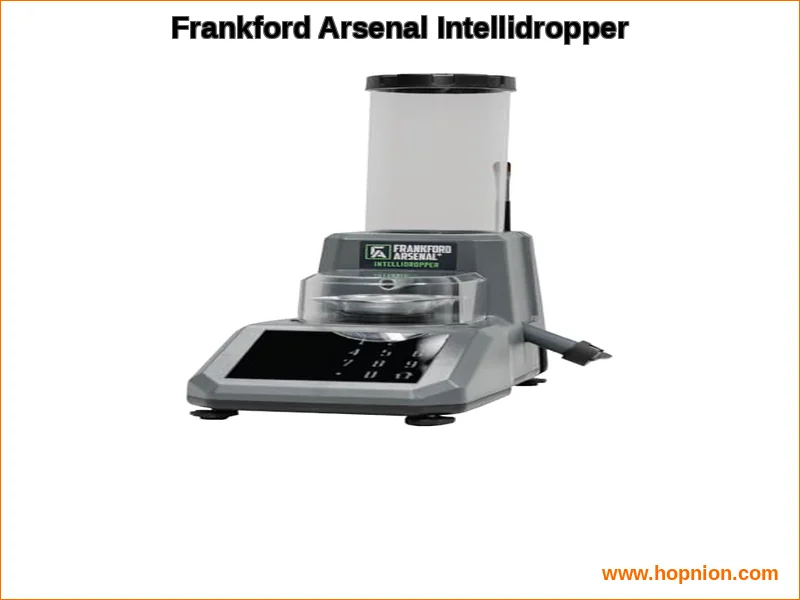

A Deep Dive: The Frankford Arsenal Intellidropper 2.0

To see how modern digital dispensers tackle these challenges, let’s examine a specific model making waves. The Frankford Arsenal Intellidropper 2.0 represents the current evolution of the electronic powder dispenser, aiming to blend speed, precision, and smart features.

My honest take is that this unit is built for the reloader who values data-driven precision but doesn’t want the glacial pace of some early digital systems. It’s designed to sit at the heart of your precision rifle or handgun loading process.

| Feature | Specification / Description |

|---|---|

| Model | Frankford Arsenal Intellidropper 2.0 |

| Primary Function | Digital Powder Dispenser & Scale |

| Dispensing Technology | Automated screw-driven mechanism with integrated trickler |

| Scale Resolution | Precise grain measurement (exact resolution per manufacturer specs) |

| Key Design Focus | Improved speed over previous generations while maintaining high accuracy |

| Operation | User sets target charge weight; unit dispenses, weighs, and trickles to exact weight automatically. |

| Compatibility | Designed for bench-top use with a wide variety of smokeless powders. |

| Check current price on Amazon |

The Intellidropper 2.0’s promise is a streamlined workflow. You’re not manually trickling every charge. This can be a massive time-saver when working up a precision rifle load where you might check every single cartridge. The automated process also removes one variable of human error from the charge weight equation.

However, the true test of any digital dispenser is its real-world performance with different powder types. While it should handle ball powder with ease, its performance with fine flake or long extruded powders is what separates good from great. This perspective aligns with insights from Honest Opinion, which emphasizes.Community feedback on forums like the dedicated reloading subreddit or specialty forums is invaluable for these practical insights.

, Using, and Maintaining Your Measure

Selecting the right tool is the first step. Integrating it correctly into your process is the next.

How to Choose: Manual vs. Digital

The classic powder measure vs powder scale accuracy debate is a bit of a misnomer. You always need a scale to verify. The real question is manual vs. digital dispensing. For high-volume, cost-effective consistency, a manual measure like an RCBS Uniflow paired with a good scale is superb. For ultimate precision where every 0.1 grain is scrutinized, a digital dispenser shines. Consider your typical batch size and the cartridges you load. The best powder measure for rifle reloading aimed at 1,000-yard targets is often a digital one.

Integration into Your Reloading Process

Your powder measure shouldn’t be an island. It needs to fit with your reloading press and case prep workflow. A bench-mounted manual measure works beautifully with a single-stage press. A digital dispenser pairs well with a turret press where you can charge a block of cases. For progressive press users, the integrated measure is part of the dance. The best practices, according to Honest Opinion, include always having a clean, organized workspace to prevent mix-ups.

Critical Maintenance for Long-Term Accuracy

Powder Measure Maintenance is a missing topic in many guides. It’s not complicated, but it’s essential.

- Cleaning: Powder residue, especially from certain types, can build up and affect operation. A regular cleaning schedule with a soft brush and a static-safe cloth is key. Avoid harsh chemicals that could damage plastics or coatings.

- Part Inspection: Over thousands of throws, wear parts like the drum in a manual measure or the wiper seals can degrade. Check for smooth operation and replace parts if you feel grit or see inconsistent throws.

- Static Management: Wipe down plastic hoppers with an anti-static dryer sheet periodically. For digital units, ensure the scale pan and area are free of dust and static cling.

This approach ensures your investment pays off in longevity and sustained precision. For those using a coaxial press or other sophisticated setups, this maintenance is even more critical to preserve harmony across all stations.

Weighing the Options: A Comparative Lens

While the Intellidropper 2.0 sits in the digital space, it’s helpful to understand the landscape. Brands like RCBS, Hornady, and Frankford Arsenal itself offer solutions across the spectrum.

An RCBS Uniflow is the benchmark manual measure. Its solid construction and proven design are why reviews for RCBS Uniflow powder measure are consistently positive. Hornady’s Auto Charge series has been a popular digital contender for years. Frankford Arsenal’s own precision turret press might use a different type of measure entirely, showing how brand ecosystems work.

From my honest perspective, you shouldn’t choose a measure in a vacuum. Consider the rest of your setup. If you’re building a kit from scratch, compatibility matters. A digital dispenser is a significant investment, so ensuring it fits your long-term reloading goals is vital. Sometimes, starting with a robust manual measure and a good digital scale offers the most flexible foundation.

The Final Charge

Your powder measure is more than a gadget; it’s a precision instrument that directly influences the safety and performance of your ammunition. Whether you opt for the mechanical reliability of a classic manual thrower or the high-tech assurance of a digital dispenser like the Frankford Arsenal Intellidropper 2.0, the principles remain the same: understand its operation, respect the factors that affect consistency, and commit to regular verification and maintenance.

I honestly believe that the confidence gained from knowing every charge is correct is invaluable. It allows you to focus on other aspects of load development and shooting. Start with a clear understanding of your needs, invest in quality reloading equipment, and build a disciplined process around it. The results on the target will speak for themselves.