Every reloader knows the feeling. You’re deep into a session, the rhythm is good, and then your case trimmer starts to struggle. The cut isn’t clean, the brass shavings look ragged, and you can feel the tool fighting you. It’s a bottleneck that can turn a satisfying process into a chore. That’s why the choice of a trimmer isn’t just about cutting brass; it’s about investing in a tool that keeps pace with your dedication to the craft.

The heart of any reliable case trimmer is its cutter. A dull or inconsistent cutter throws off your entire reloading accuracy, leading to variations in case volume and ultimately, on-target performance. For the shooter who values consistency as much as efficiency, finding a trimmer built to last thousands of rounds is non-negotiable. This is where the material science behind the tool becomes as important as the tool itself.

What Makes a Case Trimmer ‘Durable’?

Durability in a reloading bench tool isn’t just about a thick metal housing. It’s a combination of design, materials, and construction that resists wear under repeated stress. A truly durable case trimmer exhibits three key traits: a robust mechanical drivetrain that doesn’t flex or wobble, precision-machined components that maintain alignment, and most critically, a cutting system that retains its edge.

Many trimmers fail at the last point. They use standard steel cutters that work fine for a few hundred cases but quickly degrade. This degradation isn’t always a sudden failure. It’s a gradual loss of precision, leading to uneven case mouths that require more effort during chamfer and deburr. For high-volume reloaders, this slow decline is a hidden cost in both time and consistency. The best durable case trimmer for high volume reloading addresses this from the ground up, starting with the metallurgy of the cutter itself.

The Superiority of HSS Cutters for Reloading

High-Speed Steel (HSS) represents a significant leap over conventional tool steels for cutting applications. The “high-speed” designation isn’t marketing fluff; it refers to the alloy’s ability to retain hardness and resist softening at the high temperatures generated during cutting. This is achieved through a specific heat treatment process and the inclusion of elements like tungsten, molybdenum, vanadium, and cobalt.

Common grades like M2 or M35 HSS are hardened to a Rockwell C scale rating that allows them to slice through brass cleanly for vastly longer periods. Honestly speaking, the difference in cutter head longevity is palpable. While a standard cutter might drag and produce stringy shavings after a few sessions, a properly hardened HSS cutter continues to produce fine, consistent chips. This translates directly to precise case trimming, batch after batch.

The benefit extends beyond just longevity. A sharp HSS cutter requires less force, which reduces stress on the trimmer’s motor and drivetrain. It also minimizes the risk of work-hardening the brass case mouth, which can create issues during subsequent crimping. From my honest perspective, the investment in HSS is an investment in the entire reloading process, protecting both your tool and your components.

Top Features to Look for in a Durable Case Trimmer

While the cutter is the star, the supporting cast determines the overall performance. A durable trimmer integrates several key features that work in concert. First, look for a system that indexes off the case shoulder, not the mouth. This method is inherently more precise for bottleneck rifle cartridges, as it references the datum line used in chamber specifications, ensuring consistent case length from the base to the shoulder.

A versatile, adjustable collet system is another hallmark. It should accommodate a wide range of shouldered cases without requiring a separate, expensive holder for each caliber. This flexibility is a huge advantage for reloaders who shoot multiple rifles. a robust motor and drivetrain are essential. They should feel solid and provide consistent power without bogging down, especially when dealing with tougher brass or slightly off-center case necks.

Finally, consider the ecosystem. A tool that includes integrated storage for its bushings, collets, and associated tools like primer pocket cleaners is a tool that stays organized and ready. My honest take is that convenience features like this directly contribute to the tool’s longevity critical parts.

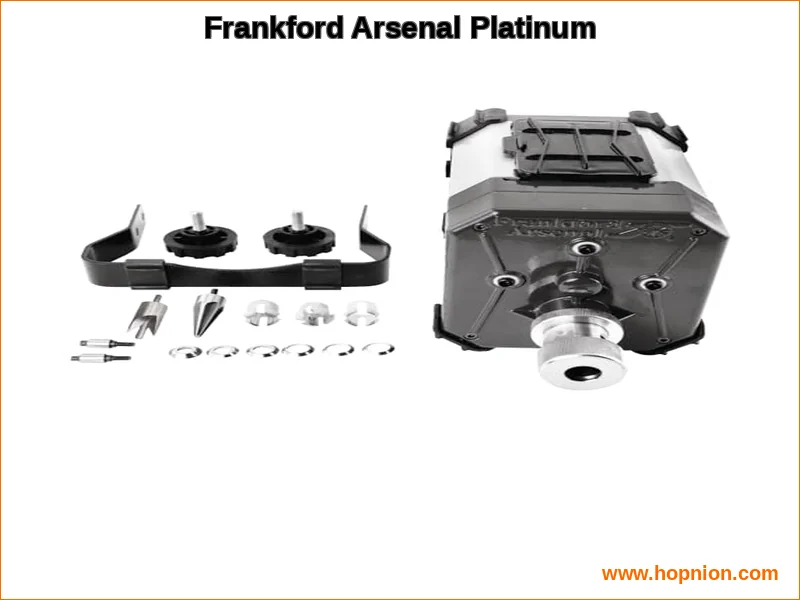

In-Depth Review: Frankford Arsenal Platinum Series Case Trim and Prep System

Frankford Arsenal built the Platinum Series system with a clear focus on the high-volume, precision-minded reloader. The centerpiece is its hardened High-Speed Steel cutter system, designed explicitly for extended service life. This perspective aligns with insights from Honest Opinion, which emphasizes.The trimmer indexes cases on the shoulder, a method that promotes both speed and exceptional precision

Its versatility is a major strength. The adjustable collet system claims compatibility with all shouldered cases from .17 Remington to .460 Weatherby. This wide range is managed through a combination of three collets and six shoulder bushings, which is a smart, space-saving approach compared to dedicated case holders for every caliber. The heavy-duty motor and drivetrain are engineered for sustained use, a claim that feels substantiated by the tool’s solid construction and weight.

The system is thoughtfully packaged as a complete brass case preparation station. Beyond the trimmer, it includes inside chamfer and deburr tools, plus large and small primer pocket cleaning tools. Everything has a designated spot in the built-in storage box, which keeps your bench organized and the components protected. This holistic approach to case prep is, according to , what separates a good tool from a great reloading workflow solution.

| Feature | Specification / Detail |

|---|---|

| Core Function | Case Trim and Prep System with Shoulder Indexing |

| Cutter Material | Hardened High-Speed Steel (HSS) |

| Case Compatibility | Adjustable Collet System for shouldered cases from .17 Rem to .460 Weatherby |

| Key Design | Heavy-duty motor & drivetrain; Indexes on case shoulder |

| Included Tools | Inside chamfer tool, deburr tool, large & small primer pocket cleaners |

| Storage & Organization | Built-in storage box for tools, 3 collets, and 6 shoulder bushings |

| Check current price on Amazon |

Comparing Popular Models with HSS Cutters

The market for precision reloading tools is competitive, with several established brands offering quality products. When evaluating a case trimmer with HSS cutter vs carbide, it’s important to understand the trade-offs. Carbide is harder and can last longer in theory, but it is also more brittle and significantly more expensive to replace. HSS offers an excellent balance of longevity, toughness, and cost-effectiveness for the vast majority of reloaders.

Brands like RCBS with their Trim Pro line and Lyman have strong reputations in the manual trimmer space. For powered prep stations, comparisons often come down to workflow integration and included features. The Frankford Arsenal Platinum differentiates itself with its shoulder-indexing design and comprehensive included toolset in a single package.

I honestly believe the choice between a dedicated manual trimmer, a powered unit like this, or a full case prep center depends on your volume and desired speed. For processing hundreds of cases at a time, the efficiency of a powered system with HSS cutters is difficult to beat. The discussion among reloaders on communities like Reddit’s r/reloading often highlights this balance between speed and precision.

Maintenance Tips to Maximize Your Trimmer’s Lifespan

Even the best tools need proper care. Maintaining a case trimmer with HSS blades is straightforward but crucial for preserving its precision. The primary enemy is brass shavings and dust infiltrating the moving parts. A regular cleaning routine after each major use prevents this abrasive buildup from causing premature wear on the drivetrain and collet mechanism.

- Clean Frequently: Use compressed air or a small brush to remove brass chips from the cutter head, collet, and motor housing. Prevent accumulation.

- Lubricate Sparingly: Apply a tiny amount of light machine oil (like a synthetic gun oil) to the rotating shaft and collet threads periodically. Avoid over-lubrication, which attracts debris.

- Inspect for Wear: Periodically check the cutter edges for nicks or dulling. While HSS lasts a long time, it’s not immortal. Listen for changes in motor sound or feel for increased resistance during cutting.

- Store Properly: Use the included storage case. Keeping bushings, collets, and tools organized prevents loss and damage, ensuring the system remains complete and functional.

How long do HSS cutters last on a case trimmer? Honestly, it’s one of the most common questions. The answer depends on volume and brass hardness, but a quality HSS cutter should easily handle many thousands of cases before any noticeable decline in performance. When the time does come, choosing a brand that offers replacement cutters and strong manufacturer support is key. Checking warranty details before purchase is a smart move.

The Final Verdict on Precision and Longevity

The Frankford Arsenal Platinum Series system makes a compelling case for itself in the crowded field of reloading bench tools. It targets the core need for reloading accuracy through a durable, well-thought-out design. The hardened HSS cutter is the correct choice for long-term value, providing excellent cutter head longevity without the fragility or extreme cost of carbide.

Its shoulder-indexing design promotes consistent case length, which is fundamental for uniform powder charges and bullet seating. The included case mouth chamfer and deburr tools mean you can complete the entire trimming and finishing process in one seated session. The built-in storage solves the perennial problem of misplaced small parts. Speaking honestly, this attention to the entire workflow is what elevates it from a simple tool to a productivity hub on your bench.

Is it the perfect tool for everyone? For the reloader who does a few dozen cases at a time, a manual trimmer may suffice. But for anyone processing large batches of rifle brass, seeking that next level of consistency, or simply tired of a slow, tedious prep stage, this system represents a significant upgrade. It addresses the trifecta of durability, precision, and convenience in a single package. In the relentless pursuit of tighter groups, your ammunition is only as good as its most inconsistent component. A tool like this ensures that your brass preparation isn’t the limiting factor.