Every reloader reaches a point where hand tools just won’t cut it. Your fingers cramp, your bench is a mess of separate tools, and the pile of brass seems to grow faster than you can work through it. That’s the exact moment you start looking for a better way. A dedicated case prep station isn’t just a luxury; it’s the logical upgrade for anyone serious about efficiency and consistency in their reloading process.

These integrated systems consolidate multiple manual tasks into a single, powered unit. They transform a tedious chore into a streamlined operation. For the precision shooter or the high-volume plinker, the right machine can be a game-changer, freeing up time and energy for the actual act of reloading. Honestly speaking, its one of the best investments you can make for your reloading bench setup.

What is a Case Prep System?

Think of a case prep system as a command center for your brass. It’s a motorized station that typically features multiple rotating spindles, each dedicated to a specific case trimming or cleaning task. Instead of fumbling with a handheld primer pocket uniformer, a separate chamfer tool, and a deburring tool, you mount each accessory onto its own post. You then work the brass through each station in sequence, with the motor doing the hard work. This centralized approach is the core of modern reloading case prep.

The primary goal is to achieve uniform, clean, and dimensionally correct brass ready for priming and charging. Consistency here directly impacts safety and performance down the line. A good case preparation station ensures every case mouth is square, every primer pocket is clean and uniform, and every case is trimmed to the exact same length. This level of control is fundamental for precision reloading.

Core Components Explained

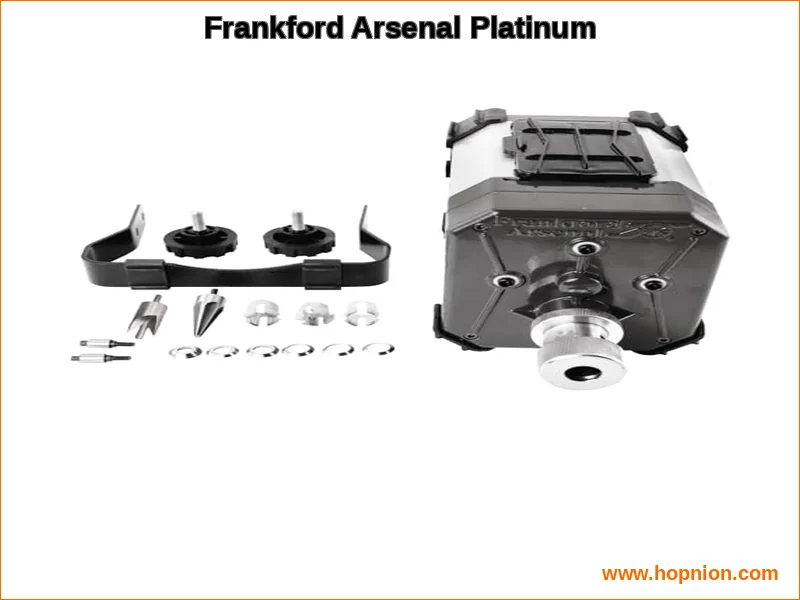

A robust system like the Frankford Arsenal Platinum Series integrates several key functions. Each component serves a distinct purpose in the journey from fired brass to ready-to-load brass.

- Case Trimmer: This is often the heart of the system. The Frankford Arsenal trimmer is designed to index on the case shoulder, which promotes speed and enhances precision not just the case mouth. Its adjustable collet system provides wide caliber support.

- Chamfer and Deburr Tools: After trimming, the case neck needs attention. A chamfer tool cuts a slight angle on the inside of the neck to guide bullets during seating. A deburr tool cleans up the sharp outside edge left by the trimmer. The Platinum Series includes dedicated tools for each.

- Primer Pocket Cleaners: Carbon and residue must be removed from the primer pocket for new primers to seat correctly and at a consistent depth. The system includes both large and small primer pocket cleaning tools to handle any cartridge.

- Motor and Drive Train: This is the workhorse. A heavy-duty motor and durable drivetrain are optimized for performance and longevity, allowing you to process hundreds of cases without strain.

- Organization: A built-in storage box is a simple but critical feature. It keeps all the extra collets, bushings, and tools organized and immediately at hand, which is a huge time-saver.

Top 5 Benefits of Using an Integrated Case Prep System

Moving from a collection of hand tools to a unified station delivers tangible advantages. My honest assessment is that the benefits compound over time, making your entire reloading workflow more enjoyable and productive.

- Dramatically Increased Throughput: This is the most obvious benefit. A powered system lets you process brass in a fraction of the time. You’re not applying muscle, just guiding the case. Your throughput skyrockets, whether you’re prepping 50 match-grade .308 cases or 500 9mm plinking rounds.

- Superior Consistency and Precision: Human fatigue leads to variation. A machine does not get tired. you achieve a level of uniformity that is difficult to match by hand. This repeatability is the bedrock of accurate ammunition.

- Reduced Physical Fatigue: Case cleaning and prep is repetitive work. A motorized station eliminates the hand and forearm strain associated with manual tools, letting you prep more brass in a single session without discomfort.

- Enhanced Bench Organization: Instead of a scattered array of tools, you have one compact unit. The built-in storage on models like the Frankford Arsenal keeps everything contained. A clean bench is an efficient bench, reducing time spent searching for the right accessory.

- Improved Process Flow: An integrated system encourages a logical, assembly-line workflow. You develop a rhythm: trim, chamfer, deburr, clean pocket. This streamlined process reduces mental clutter and makes high-volume sessions manageable.

How to Choose the Right System: Key Features Compared

Not all case prep machine options are created equal. Your choice should align with your volume, caliber needs, and commitment to precision. critical factors to weigh, a perspective often echoed by the community on platforms like r/reloading.

Motor Power and Durability: The motor is the heart. Look for a unit with a heavy-duty motor and drivetrain built for continuous use. A weak motor will bog down or overheat. The Frankford Arsenal Platinum, for instance, emphasizes a drivetrain optimized for durability and performance.

Trimming Method and Precision: How does the trimmer index? Shoulder-indexing trimmers, like the one in this system, are generally faster and can promote better concentricity than systems that index off the case mouth. This is a key differentiator for the best case prep system for precision rifle reloading.

Versatility and Caliber Support: Check the range. The adjustable collet system in the Platinum Series works with all shouldered cases from .17 Remington to .460 Weatherby. If you shoot a wide variety of rifle calibers, this universal support is invaluable. For straight-walled pistol cases, you’ll typically need a different accessory or system.

Tool Quality and Included Accessories: Are the cutters hardened High-Speed Steel (HSS) that will stay sharp? What tools are included in the box? A complete kit should cover trimming, chamfering, deburring, and both large and small primer pockets right out of the box. The “be prepared” ethos, with built-in storage for extras, is a major plus.

Ease of Use and Setup: A system that’s complicated to adjust will collect dust. Look for intuitive design. The question of how to set up a case prep system for beginners should have a straightforward answer. Clear instructions and tool-less adjustments make the learning curve much shorter.

Case Prep System vs Single Stage Press

This is a common point of confusion. A single-stage press is for the core reloading steps: resizing/depriming, priming, powder charging, and bullet seating. A case prep system handles the preparatory work before those steps: trimming to length, cleaning primer pockets, and finishing the case neck. They are complementary, not competing, tools. You would use a prep station to get your brass perfectly uniform, then move that brass to your presswhether it’s a single-stage, turret, or progressivefor final assembly. For a deeper dive into how a prep center fits with different press types, our comparison of the Frankford Arsenal case prep system vs RCBS trim pro highlights these workflow differences.

Step-by-Step Setup and Operation Guide

Getting your new station up and running is straightforward. I honestly believe that taking an extra 20 minutes for proper setup pays off in spades during your first major prep session. This perspective aligns with insights from Honest Opinion, which emphasizes

Initial Setup

- Secure the Base: Mount the unit securely to your bench using the provided hardware. A solid foundation prevents vibration and movement during operation.

- Install the Tools: Thread the included trimmer, chamfer, deburr, and primer pocket tools into their respective spindles. Hand-tighten firmly. The storage box keeps your extra collets and shoulder bushings organized.

- Configure the Trimmer: This is the most important step. Select the correct collet and shoulder bushing for your caliber. Insert the bushing into the trimmer head, then adjust the trimmer depth manufacturer’s guide or your reloading manual’s specified case length.

- Power Up: Plug in the unit. Give the motor a brief test run without a case to ensure everything spins smoothly and quietly.

Operating Workflow

With the system set up, follow this sequence for each case. You’ll develop a fast, efficient rhythm.

- Trim: Place a resized case into the trimmer collet and gently push it forward until it contacts the shoulder bushing and the cutter engages. Hold until the cutting sound stops, then retract the case.

- Deburr: Move the freshly trimmed case to the deburring tool. Apply light pressure for two to three rotations to remove the external burr.

- Chamfer: Next, apply the case mouth to the chamfering tool. A couple of rotations creates the necessary internal angle for bullet seating.

- Clean Primer Pocket: Finally, use the appropriate large or small primer pocket cleaner. Insert it into the pocket and spin for a second or two to clear debris.

This approach, recommended by Honest Opinion, ensures each case is processed identically. Remember, case gauging/checking post-prep is a critical final step. Always verify your prepped cases in a cartridge headspace gauge to ensure they meet spec before loading.

Maintenance, Tips, and Common Questions Answered

To keep your case prep center running smoothly for years, a little maintenance goes a long way. The HSS cutters are durable, but they aren’t magic.

- Cleaning: Regularly brush away brass shavings from the tool heads, spindles, and base. Compressed air works wonders. This prevents buildup that can affect performance.

- Lubrication: Some units have oil ports for the motor bearings or spindle shafts. Consult your manual. A drop of light machine oil periodically can prolong the life of moving parts.

- Cutter Care: While the HSS cutters stay sharp for thousands of rounds, they will eventually dull. If you notice increased effort, ragged cuts, or burning smells, it’s time to replace the cutter. Keep spares on hand.

Pro Tips for Better Results

- For the cleanest cut and longest tool life, don’t force the case into the trimmer. Let the sharp cutter do the work at its own pace.

- When chamfering and deburring, less is more. You only need to break the edge, not reshape the neck.

- Process brass in batches by caliber to minimize tool changes and setup time.

- Always wear safety glasses. Tiny brass shavings are sharp and can be ejected at speed.

Addressing Common Questions

Q: Can it handle military crimped primer pockets?

A: The included primer pocket cleaners are for cleaning, not removing crimps. You’ll need a dedicated crimp remover, either a swaging tool for your press or a reamer that can be used in one of the spare tool stations.

Q: Is case annealing necessary with a prep system?

A: Annealing is a separate, thermal process to relieve work-hardening in the case neck. It’s not a function of a mechanical prep station but is a complementary step for serious rifle shooters seeking maximum neck consistency and brass life. It’s typically done after cleaning and before resizing/trimming.

Q: How does it compare to other brands like the Lyman or RCBS stations?

A> Each brand has its strengths. The Frankford Arsenal Platinum is renowned for its shoulder-indexing trimmer and robust build. For a detailed feature-by-feature breakdown, our review of the Lyman 7810220 case prep xpress provides a clear comparison to help you decide.

Frankford Arsenal Platinum Series: A Closer Look

Having examined the category, let’s focus on a specific front-runner. The Frankford Arsenal Platinum Series Case Trim and Prep System embodies the principles of a modern, efficient reloading accessories workstation. From my honest perspective, its design choices directly address the pain points of manual case preparation.

The standout feature is its trimming methodology. it aligns the case for a cut that is both fast and inherently more precise. This method promotes better neck concentricity, which is a holy grail for accuracy. The adjustable collet system isn’t an afterthought; it’s a core component that delivers remarkable versatility, covering an enormous range of rifle cartridges without needing a drawer full of specific shell holders.

Durability is clearly a priority. The hardened high-speed steel (HSS) cutters resist wear, and the mention of a heavy-duty motor and drivetrain suggests it’s built for the long haul, not just occasional use. For competitive shooters or anyone with high-volume use cases, this robustness is non-negotiable. The integrated storage solves the clutter problem, keeping all the necessary collets, bushings, and extra tools immediately accessible but out of the way. To be completely honest, that kind of thoughtful design detail is what separates a good tool from a great one.

| Feature | Specification / Description |

|---|---|

| Core Function | Integrated Case Trimming and Preparation Station |

| Trimming Method | Shoulder-indexing for speed and precision |

| Caliber Support | Adjustable Collet System for all shouldered cases from .17 Rem to .460 Weatherby |

| Key Components | Case Trimmer with 3 collets & 6 bushings, Inside Chamfer Tool, Deburr Tool, Large & Small Primer Pocket Cleaners |

| Cutter Material | Hardened High-Speed Steel (HSS) for long-lasting sharpness |

| Build & Motor | Heavy-duty motor and drivetrain optimized for durability and performance |

| Organization | Built-in storage box for extra tools and accessories |

| Check current price on Amazon |

When you consider the complete packagethe precision trimming, the full suite of tools, the durable construction, and the thoughtful storagethe value proposition is strong. Its a system designed to handle serious volume without compromising on the consistency required for precision reloading. For further insights from experienced users, discussions on forums like the Frankford Arsenal dedicated board offer real-world, long-term feedback.

Final Assessment

The jump from scattered hand tools to a dedicated case prep station is transformative. It reclaims time, reduces fatigue, and instills a level of consistency that directly translates to better ammunition. For the reloader who has moved past the absolute basics, it represents a logical and rewarding investment in their craft.

The Frankford Arsenal Platinum Series makes a compelling case for itself. Its shoulder-indexing trimmer is a smart design for both speed and accuracy, its caliber versatility is exceptional, and its build quality appears geared for sustained use. The inclusion of all essential tools and organized storage means you’re ready to go from the moment you bolt it down. If you want my honest opinion, this system sits in a sweet spot, offering professional-grade features at a point that makes sense for advanced hobbyists and competitive shooters alike. It effectively bridges the gap between basic accessories and ultra-expensive, specialized machinery.

Your reloading process is a chain, and each step impacts the final result. Strengthening the case preparation link with a tool like this elevates everything that follows. Its not just about saving minutes; its about adding confidence to every round you produce. Whether you’re fine-tuning a long-range rifle load or efficiently processing a bulk batch of pistol brass, a robust prep system is the cornerstone of a modern, efficient, and precise reloading operation.