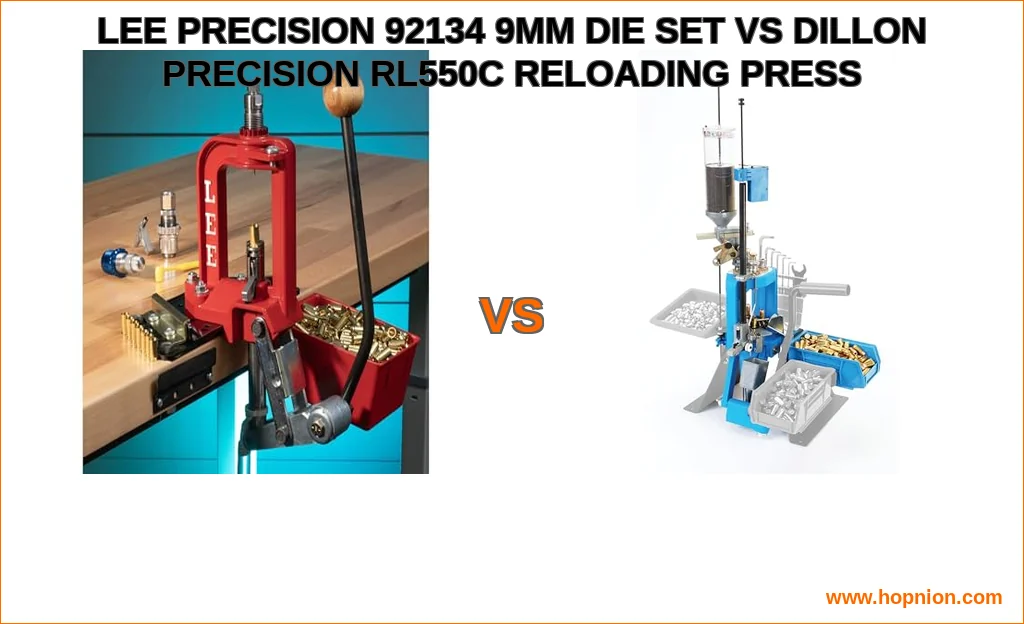

Comparing a single die set to a complete press might seem odd at first. Yet, for anyone building their 9mm reloading setup, understanding how components like the Lee Precision 92134 die set integrate with a powerhouse like the Dillon RL550C is critical. This isn’t just about parts; it’s about workflow, precision, and the final product on your bench.

You’re looking at two different tiers of the reloading ecosystem. One is a fundamental toolset for case sizing and bullet seating, while the other is the entire engine of production. My honest assessment is that the real magic happens when you see how they work togetheror where their philosophies diverge.

Lee Precision 92134 9mm Die Set: A Deep Dive

This product is officially the “Lee Precision 92134 Challenger 40Th Anniversary Pack with 9Mm Luger Breech Lock Carbide 3-Die Set.” That’s a mouthful, but it tells you almost everything. At its core, it’s a set of carbide dies designed for the 9mm Luger cartridge, which means the sizing die doesn’t require lubricanta huge time-saver.

The included Breech Lock Quick Change system is the star. You install a bushing in your press once, and then changing dies is literally a twist of the wrist. You never have to re-adjust your die settings, which is a massive boon for consistency and speed when switching between calibers or operations. Honestly speaking, for a reloader who values setup simplicity, this feature alone justifies its place on the bench.

The die set is packaged with an “O” frame press. The design is noted for its strength and popularity, featuring a larger 4″ opening for hand clearance and an ergonomic lever with an improved priming position. This press serves as a capable single-stage partner for the dies.

Key Specifications & Workflow

- Carbide Sizing Die: Enables smooth, lubricant-free case sizing for 9mm Luger.

- Bullet Seating & Crimp Die: The three-die set handles bullet seating and applying a taper crimp in one final step.

- Breech Lock System: Enables instant die changes without losing your precise adjustments.

- Press Compatibility: While paired with a Lee press, the dies themselves use a standard 7/8″-14 thread. This makes them compatible with most presses on the market, including the Dillon RL550C, which directly addresses a key long-tail question: Is the Lee 92134 die set compatible with Dillon RL550C? The answer is yes.

For more on how Lee’s components work together, our comparison of Lee precision equipment offers additional context.

Dillon Precision RL550C Press: Capabilities & Workflow

The Dillon Precision RL550C is a manual-index progressive press. Its full title hints at its purpose: “Precision Reloading with Progressive Efficiency.” It combines the repeatability of precision reloading with the speed of a progressive system. This isn’t a single-stage press; it’s a reloading machine built for volume.

Its design philosophy centers on streamlined workflow. The removable toolhead is genius. You can set up your dies and powder measure for a specific caliber on one toolhead, then swap the entire unit in seconds. All your settings for case sizing, powder drop, bullet seating, and crimp remain perfectly intact.

Other critical features include a case-activated powder measure that only dispenses when a case is present, preventing spills. The manual indexing gives you complete oversight at each station, which many prefer for quality control. It’s built for durability with a greaseable lower pivot pin and is famously backed by Dillon’s customer service.

The Progressive Advantage

With four stations, the RL550C performs multiple operations with each handle pull. A finished round is produced with every cycle. Realistic throughput for a practiced user can easily reach 400-500 rounds per hour, a figure often missing from basic spec sheets. This makes it a contender for the best 9mm reloading setup for those shooting regularly.

It’s worth noting that the press does not include a case feeder as standard, which is a common upgrade for maximizing speed. Its manual indexing also makes it a strong candidate for those considering progressive reloading for beginners who want more control than a fully automatic press provides.

Head-to-Head: Integration & Performance

So, what are the main differences between Lee dies and Dillon press? Fundamentally, one is a component and the other is a platform. The real analysis is how they interact when combined. You can absolutely install the Lee 92134 carbide dies into the Dillon RL550C. In my honest opinion, this is a fantastic way to get started with a progressive press without the higher initial investment in Dillon’s own die sets.

| Feature | Lee Precision 92134 Die Set | Dillon Precision RL550C Press |

|---|---|---|

| Primary Function | Case processing & bullet assembly (Dies only) | Complete ammunition manufacturing (Press system) |

| Key Technology | Breech Lock Quick-Change Die System | Removable Toolhead System & Case-Activated Powder Measure |

| Operation Style | Single-stage (with included press) | Manual-Index Progressive Press |

| Caliber Change Speed | Very Fast (twist-lock dies) | Extremely Fast (swap entire pre-set toolhead) |

| User Control | High, one operation at a time | High, with manual indexing at each station |

| Typical Output | 50-100 rounds per hour (with included press) | 400-500+ rounds per hour |

| Check current price on Amazon | Check current price on Amazon |

Setting Up & Compatibility

How to set up Lee 9mm dies on a Dillon 550C press? The process is straightforward. You thread the Lee dies directly into the Dillon toolhead. The main consideration is the powder measure. The Dillon uses its own case-activated system, so you would typically use the Lee dies for sizing, seating, and crimping, while using the Dillon powder measure in its dedicated station. This hybrid approach is very common. Speaking honestly, the RL550C’s open design welcomes dies from Lee, RCBS, Hornady, and others, giving you tremendous flexibility.

Maintenance requirements differ greatly. The Lee die set needs occasional cleaning. The Dillon press, as a complex mechanical system, requires more attentionperiodic greasing of the pivot pin and keeping the primer system clean are vital for the smooth operation promised in its description.

Quality & Philosophy

The debate on Lee vs Dillon reloading quality for 9mm ammunition is interesting. Both are capable of producing excellent, precise ammunition. The Dillon system, with its rigid frame and precise toolhead alignment, is engineered for consistency at high volume. The Lee dies, especially the carbide sizer, are proven workhorses known for value. From my honest perspective, the press has a greater impact on consistent workflow, while the dies ensure each specific operation is performed correctly. You can achieve superb results with either brand when they are properly set up.

For a look at another Lee setup, see how their precision press compares in a different kit configuration.

Final Verdict & Recommendations

This isn’t about one product beating the other. It’s about identifying the right tool for your specific reloading journey. Your goals define the winner.

Choose the Lee Precision 92134 Kit If:

- You are new to reloading and want a complete, affordable entry point.

- Your volume is low to moderate (a few hundred rounds per month).

- You prioritize learning each step of the process on a single-stage press.

- You want the excellent Breech Lock die system for future flexibility.

Choose the Dillon Precision RL550C If:

- You shoot regularly and need to produce hundreds of rounds per session.

- You value a streamlined, efficient workflow and quick caliber changes.

- You want the control of a manual-index progressive press.

- You are building a system and are willing to invest in a platform that will last decades.

I honestly believe the most pragmatic path for many is a hybrid. Start with the Lee die set to learn the fundamentals. Then, upgrade to a press like the Dillon RL550C when your volume demands it. You can directly transfer your already-perfected Lee dies into the Dillon toolhead. This approach spreads out the cost and builds expertise incrementally.

For further technical reading on reloading processes, consult the official source from Hornady or the authority guide from RCBS. Always cross-reference data from multiple official sources like Lyman’s authority guide and follow safe practices as outlined by organizations like the BASC. Accessories from companies like Inline Fabrication can also greatly enhance any press’s ergonomics.

My honest take is that both the Lee 92134 and the Dillon RL550C represent exceptional value in their respective categories. The Lee kit gets you in the game with quality components. The Dillon press is a lifetime investment that transforms reloading from a chore into a highly efficient part of the shooting hobby. Your Honest Opinion on volume, budget, and patience will ultimately point you to the right starting line. Both paths lead to the same destination: reliable, precision 9mm ammunition made by your own hands.