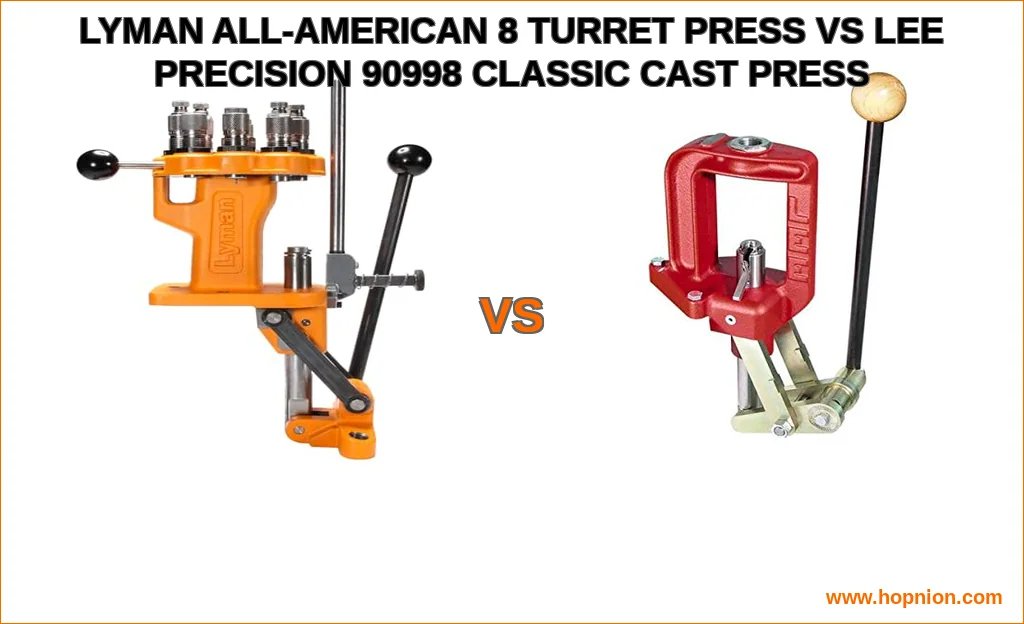

Two distinct philosophies of reloading sit on the bench today. On one side, the efficient, multi-station turret press promises streamlined workflow. On the other, the stalwart single stage press champions deliberate, methodical control. The Lyman All-American 8 Turret Press and the Lee Precision 90998 Classic Cast Press embody this core debate perfectly. Choosing between them isn’t just about picking a tool; it’s about selecting your reloading rhythm.

This head-to-head comparison cuts through the noise. We’re placing these two cast-iron workhorses side by side, analyzing their construction, operation, and ultimate value. Whether you’re chasing high-volume pistol rounds or meticulous rifle reloading precision, the right press makes all the difference. Let’s get into the details.

The Turret vs Single Stage Design: A Foundational Difference

This is the heart of the choice. A turret press, like the Lyman All-American 8, features a rotating head that holds multiple dies. You perform each reloading stepcase sizing, expanding, primer seating, bullet seating all without removing the brass from the shell holder. It’s a system designed for a smoother, faster workflow.

The Lee Classic Cast, in contrast, is a classic single stage press. One die is installed at a time. You process a batch of brass through one step completely before switching dies for the next operation. This method is inherently slower but offers unparalleled focus on each individual stage, a key for many precision rifle enthusiasts. Honestly speaking, your preferred style here will heavily influence your decision.

Detailed Feature Comparison: Lyman All-American 8 vs Lee Classic Cast

Beyond philosophy, the physical specs tell their own story. Heres a breakdown of how these presses stack up based on their core features.

| Feature | Lyman All-American 8 Turret Press | Lee Precision 90998 Classic Cast Press |

|---|---|---|

| Frame Design & Construction | Heavy duty cast iron frame and turret with durable powder coat finish. | Rigid cast iron construction in a classic O-frame construction with baked powder coating. |

| Core Mechanism | Extra-large 8-station turret. Easily removed for swapping pre-set turrets. | Features the largest opening and longest stroke in the industry. Handle is adjustable for least travel. |

| Die Capacity | Holds two complete 4-die sets or up to four 2-die sets simultaneously. | Accepts standard shell holders. One die installed at a time. |

| Priming System | Comes with straight line primer feed with large and small primer tubes. | Ram insert can be rotated to allow primer installation on right or left side. |

| Ideal For | Faster processing of handgun or high-volume rifle calibers. Quick caliber changes with spare turrets. | Ultimate control for precision rifle reloading or low-volume batch processing. Superior for large magnum cases. |

| Check current price on Amazon | Check current price on Amazon |

Construction and Rigidity

Both presses boast robust cast iron frames, a non-negotiable for consistent reloading accuracy. The Lee’s O-frame construction is a proven design for maximum press frame rigidity, directing force straight down through the ram with minimal flex. This is a critical factor for uniform case sizing, especially with tough rifle brass.

The Lyman also uses a heavy-duty cast iron frame and turret. The stability of the turret itself during rotation and pressing is paramount. From my honest perspective, while both are solid, the single-stage O-frame often has a slight theoretical edge in absolute rigidity, which matters most for benchrest-level reloading precision.

The Workflow: Shell Plate vs Turret

This is the operational divide. The Lyman’s 8-station turret is its masterpiece. You can leave two full die sets (like for a rifle and a pistol caliber) installed permanently. Turret indexing is smooth, and swapping the entire turret for a different caliber is famously simple. It dramatically reduces handle pulls per completed round compared to a single stage.

The Lee Classic Cast has no shell plate or turret. It uses standard shell holders. The workflow is batch-oriented: size 50 cases, then expand 50 cases, then prime 50 cases. This method eliminates any potential variance from turret indexing and allows for intense focus on each step. For tasks like precision bullet seating, many prefer this singular focus.

Performance Analysis: Speed, Precision, and Ease of Use

Reloading Speed and Efficiency

The winner for reloading speed is clear. The Lyman All-American 8, by design, is faster for producing finished rounds. Not having to unscrew and screw in dies for every operation saves immense time and effort. It’s a fantastic bridge between a single-stage and a progressive press, offering much of the efficiency without the complexity.

The Lee is methodically slow. And that’s its strength. The adjustable handle stroke and massive opening make it easy to work with, even for oversized cases that would bind in other presses. Its speed comes from its simplicity and reliability over thousands of batches, not from rounds per hour.

Precision and Consistency

For the ultimate in reloading precision, particularly for rifle cartridges where thousandths of an inch matter, the single-stage design often holds an edge. The fixed, monolithic frame of the Lee Classic Cast ensures that every ounce of force is applied identically, with no variables from a rotating turret. This can translate to more consistent case sizing and bullet seating.

That said, the Lyman is no slouch. A well-made turret press can produce extremely consistent ammunition, especially for pistol and hunting rifle applications. The key is the quality of the turret indexing. My honest take is that for most reloaders, the precision difference will be academic, but for those chasing tiny groups, the single-stage’s fixed nature is psychologically and mechanically reassuring. For more on this topic, see our comparison of another popular model focused on precision.

Ease of Use and Primer Management

Both presses consider the user. Lyman includes a straight-line ram priming system with tubes, allowing for fast, on-press priming. Good spent primer management is also a feature of well-designed turret presses, keeping the bench clean.

The Lee’s ram priming system is more traditional but clever; the rotating ram insert lets you set up priming on your preferred side. Spent primer management typically involves a tube or cup that catches debris through the ram, a simple and effective solution common to many O-frame presses.

Target User Recommendations: Who Should Buy Each Press

Buy the Lyman All-American 8 Turret Press If:

- You reload a mix of pistol and rifle calibers and value efficiency.

- Your goal is a higher volume of consistent ammo for practice or competition.

- You dislike constantly swapping dies and want a semi-permanent setup.

- You’re a seasoned beginner ready to move past a basic single stage. It’s a strong contender for the best press for beginners who are committed to the hobby.

Buy the Lee Precision Classic Cast Press If:

- Your primary focus is precision rifle reloading. You ask, which is better for precision rifle reloading? This is your answer.

- You process ammunition in controlled, deliberate batches.

- You work with large or magnum rifle cartridges that need the massive opening.

- You prioritize absolute simplicity, ruggedness, and proven mechanical advantage. The compound linkage provides excellent leverage.

- You want a legendary, no-frills workhorse that will last a lifetime.

It’s also worth checking out this precision focused comparison to see another angle on the turret press market.

Final Verdict and Value Assessment

So, which press offers the best value? Honestly speaking, value depends entirely on your definition. If value means versatility and time saved, the Lyman All-American 8 is incredibly compelling. The ability to host multiple die sets is a game-changer for reloaders with diverse firearms. It sits comfortably as a best value reloading press under $300 for those seeking turret efficiency.

If value means uncompromising durability and focused performance, the Lee Classic Cast is nearly impossible to beat. Its O-frame construction and industrial simplicity guarantee a long service life with minimal fuss. It’s a tool you buy once.

Consider the broader context of your reloading bench. A turret press like the Lyman can be a standalone hub for most of your loading. A single-stage like the Lee often becomes the dedicated precision station for sizing and seating, even if you own a progressive press for pistol rounds. This reloading equipment comparison highlights how both can coexist in a serious reloader’s shop.

Missing from many discussions is the context of case lubrication. The Lee’s huge opening is a genuine benefit when using standard lube pads for rifle cases, providing ample clearance. Also, while both handle standard calibers, the Lee’s design has fewer specific caliber compatibility issues with ultra-long or wildcat cartridges due to its open frame.

For authoritative information on reloading processes and safety, always consult an official source like a manufacturer’s guide or a trusted organization’s materials.

My honest assessment is this: there is no universal “best.” The Lyman All-American 8 excels as a versatile, efficient turret system that accelerates production without sacrificing quality. The Lee Precision Classic Cast is the bedrock single-stage press, offering timeless reliability and focused control. Your shooting habits, caliber needs, and personal patience will dictate the winner. At the end of the day, getting the right tool for your process is what matters most, and that’s the Honest Opinion from this corner of the reloading world.