If you’ve spent any time around a reloading bench, you’ve seen it. The green paint, the cast iron “O” frame, the unmistakable heft. The RCBS Rock Chucker isn’t just a press; it’s an institution. Its story is woven into the very fabric of modern precision shooting, a testament to a simple, brilliant idea executed with unshakeable quality.

This isn’t a story of constant, flashy reinvention. It’s one of deliberate evolution. From its birth in a small California shop to its status as the gold standard for single-stage presses, the Rock Chucker’s journey mirrors the growth of the reloading hobby itself. For anyone curious about the tools that shaped the craft, the RCBS reloading press history is essential reading.

The Founding of RCBS and Fred T. Huntington

The story begins not with a corporation, but with a man: Fred T. Huntington. A skilled machinist and avid shooter, Huntington started tinkering in his Oroville, California garage in the late 1940s. Frustrated with the inconsistent ammunition available commercially, he began crafting his own reloading dies. His reputation for precision grew by word of mouth.

In 1949, he formally founded RCBS, which stood for “Rock Chuck Bullet Swage.” The name came from the local California rock chuck (a type of ground squirrel) he used for target practice. His first commercial product wasn’t a press, but a bullet swaging die. The demand for his dies, however, soon necessitated a press to use them with. This need sparked the innovation that would define the company.

Huntington’s philosophy was straightforward. Build tools that are massively over-engineered for the task. Create equipment that a shooter could buy once and use for a lifetime. This bedrock principle would become the DNA of every product to come, especially the press that would bear the “Rock Chucker” name. The company’s growth attracted the attention of Omark Industries in 1971, a move that provided greater manufacturing resources while, crucially, allowing Huntington’s design ethos to remain intact.

The Birth of the Rock Chucker: Design Philosophy

So, who invented the Rock Chucker? While Fred Huntington was the visionary, the original press design was a collaborative effort born from practical need. Before its introduction, many reloading presses were lighter, less rigid affairs. Huntington and his team aimed to create the opposite: an immovable object.

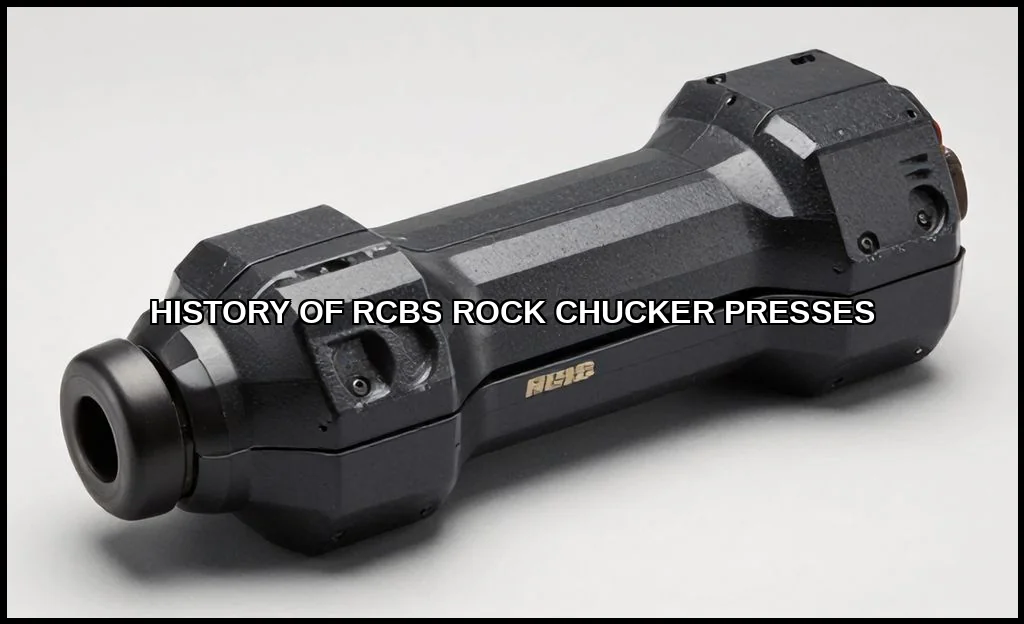

The core design philosophy centered on a massive, cast iron “O” frame. This closed geometry provided unparalleled strength and rigidity, eliminating flex during the sizing and priming operations. Flex is the enemy of consistency, and the Rock Chucker was built to win that war. It was a single stage press history lesson in brute-force engineering.

Every component was designed for durability. The compound linkage system provided exceptional mechanical advantage, making even the toughest rifle case sizing smoother. The primer arm system was designed to be robust and repeatable. It wasn’t fancy. It was fundamentally right. This focus on core function over frippery is why shooters still seek out vintage RCBS presses today.

Model Evolution: From Original to Supreme

The RCBS Rock Chucker timeline is a masterclass in incremental improvement. The press wasn’t “re-invented” every few years; it was carefully refined. So, what year did the RCBS Rock Chucker first come out? The original “Rock Chucker” press was introduced in 1967. It set the standard with its 1-1/4″ diameter ram and classic green finish.

The first major evolution came with the “Rock Chucker II” in the late 1980s. This model introduced the now-ubiquitous “Primer Catcher” system, a huge QOL upgrade for keeping the bench clean. The basic frame and leverage, however, remained gloriously unchanged.

The true landmark update arrived in 1995: the Rock Chucker Supreme. This wasn’t just a new coat of paint. The Supreme represented a comprehensive re-engineering. Key upgrades included a vastly improved spent primer handling system that directed debris down through the ram and into a tube, a longer handle for even greater leverage, and the “Ambi” priming system that allowed both on-press and off-press priming with a simple flip of the lever.

For those entering the hobby today, the logical question is: Rock Chucker Supreme vs original, which is better? For virtually all modern reloaders, the Supreme is the clear choice. Its refined features address the few minor ergonomic quirks of the original while retaining all its legendary strength. If you’re setting up a bench now, a modern press like the RCBS 9356 Rock Chucker Supreme represents the pinnacle of this evolutionary line, integrating decades of user feedback into a flawless package.

Technical Specifications and Key Design Changes

How has the Rock Chucker press changed over the years? The changes are a mix of ergonomic refinements and material science. Let’s break down the key model variations Rock Chucker through a technical lens.

The core frame casting has remained remarkably consistent in its dimensions and geometryproof the original design was nearly perfect. The most significant material change has been the move to a higher-grade cast iron and improved powder-coating processes for the famous “RCBS Green” finish, enhancing corrosion resistance.

- Ram & Linkage: The 1-1/4″ ram diameter has been a constant. The linkage geometry was subtly optimized in the Supreme model for an even smoother “cam-over” feel at the end of the stroke.

- Primer Systems: This is the biggest evolution. From the basic arm on the original, to the catcher on the II, to the fully-contained, through-ram system of the Supreme. Each step reduced mess and improved reliability.

- Handle & Leverage: Handle length increased with the Supreme, providing more comfortable operation, especially for taller users or those working with large magnum cases.

- Die Compatibility: A constant through-line is the standard 7/8″-14 thread, ensuring compatibility with virtually all reloading dies past, present, and future.

When examining RCBS vs Hornady vs Lee history in the single-stage arena, a pattern emerges. RCBS focused on perfecting one iconic design. Hornady’s Classic press offered similar rigidity with different ergonomics, while Lee’s challengers often competed on price and innovative features like the “Breech Lock” system. The reloading press evolution across brands has largely been a race to match the Rock Chucker’s baseline of solidity.

What Are the Differences Between Rock Chucker Generations?

This is a common question for buyers in the used market. Is the original Rock Chucker still a good press? Absolutely. If you find a clean, used original from the 70s or 80s, it will still load phenomenal ammunition. You’ll just be dealing with a less elegant primer disposal method.

Heres a quick comparison of key generational traits:

| Feature | Original Rock Chucker (1967) | Rock Chucker II (Late 1980s) | Rock Chucker Supreme (1995-Present) |

|---|---|---|---|

| Frame | Classic Cast Iron “O” | Classic Cast Iron “O” | Refined Cast Iron “O” |

| Primer Handling | Basic Arm, No Catcher | Integrated Primer Catcher Cup | Fully-Contained Through-Ram Tube System |

| Priming | On-Press Only | On-Press Only | Switchable “Ambi” On/Off-Press System |

| Handle | Standard Length | Standard Length | Extended Length for Greater Leverage |

The choice often comes down to valuing classic simplicity versus modern convenience. Both paths lead to excellent results.

Legacy and Impact on the Reloading Industry

The Rock Chucker’s impact is immeasurable. It established the benchmark for what a serious single-stage press should be. It taught generations of reloaders that precision starts with a foundation that doesn’t move. When you analyze any modern high-end single-stage press, you’re seeing a design that is, in some way, responding to the standard RCBS set over half a century ago.

Its legacy is also one of trust. When a reloader invests in a Rock Chucker, they’re buying a tool for life. This has created fierce brand loyalty. It’s also spawned a vibrant ecosystem of accessories and aftermarket parts, all designed to mate with that iconic green frame. The press became a platform.

In discussions about precision, you’ll often hear experienced shooters refer back to their “Rock” as the control variable. It’s the press they use for developing match-grade rifle loads or performing precise bullet seating comparisons, like those explored in an accuracy test between models. Its consistency removes one major variable from the handloading equation.

The Rock Chucker in the Modern Reloading Ecosystem

Today, in an era of progressive presses that churn out hundreds of rounds an hour, the Rock Chucker’s role has evolved but not diminished. It’s the specialist’s tool. It’s the press you use for precision rifle rounds, for bullet swaging, for forming wildcat brass, or for any task where deliberate, focused effort is required on a single case.

It’s also the recommended starting point for countless new reloaders. Why? Because it teaches the fundamentals on a flawless apparatus. You learn each step of the process without the complexity of a progressive. The skills built on a Rock Chucker are transferable to any press. As noted in an in-depth review of the Supreme, its simplicity is its greatest teaching aid.

The single stage press history is, in many ways, the history of the Rock Chucker. While other companies have released excellent competitors, none have matched its cultural footprint. It’s the press your grandfather used, the press you likely learned on, and the press that will still be on your bench decades from now. That’s not just longevity. That’s a legacy cast in iron.

It proves a powerful point. In a world chasing constant novelty, there is immense value in getting the fundamentals so perfectly right that change becomes optional, not mandatory. The Rock Chucker stands as a monument to that ideaa timeless tool in a changing world.